Cement-based stone-like road edge stone and preparation method and forming device thereof

A molding equipment and curb stone technology, applied in the field of artificial stone, can solve the problems of reduced strength and performance, high mold investment cost, short service life, etc., and achieve the effects of improving compactness, improving surface finish, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A cement-based imitation stone type curb, comprising the following components by weight: 14-16% of cement, 26-29% of yellow sand, 37-39% of crushed stone, 11-13% of gypsum, 6- 9% water, yellow sand is fine yellow sand with an average particle size of 0.25mm-0.35mm and a fineness modulus of 2.2-1.6, the particle size of gypsum is 0.1-10mm, and the particle size of crushed stone is less than 16mm.

[0071] When preparing curb stone ingredients, due to the influence of uncertain factors such as different weighing tools and different operators, the proportion of ingredients cannot be guaranteed to be more accurate. Therefore, in the present invention, 14-16% of cement, 26-29% of yellow sand, 37-39% of crushed stone, 11-13% of gypsum, 6-9% of water are all range values, which means that deviations within these ranges are allowed, but not necessarily specific. ratio.

[0072] The invention adopts a brand-new formula, reduces the specific gravity of cement, not only saves the...

Embodiment 2

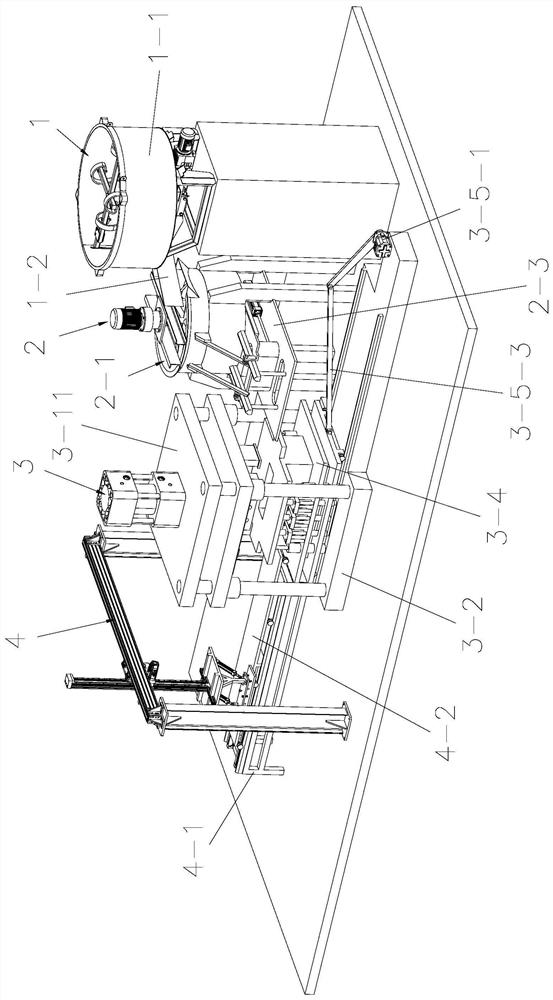

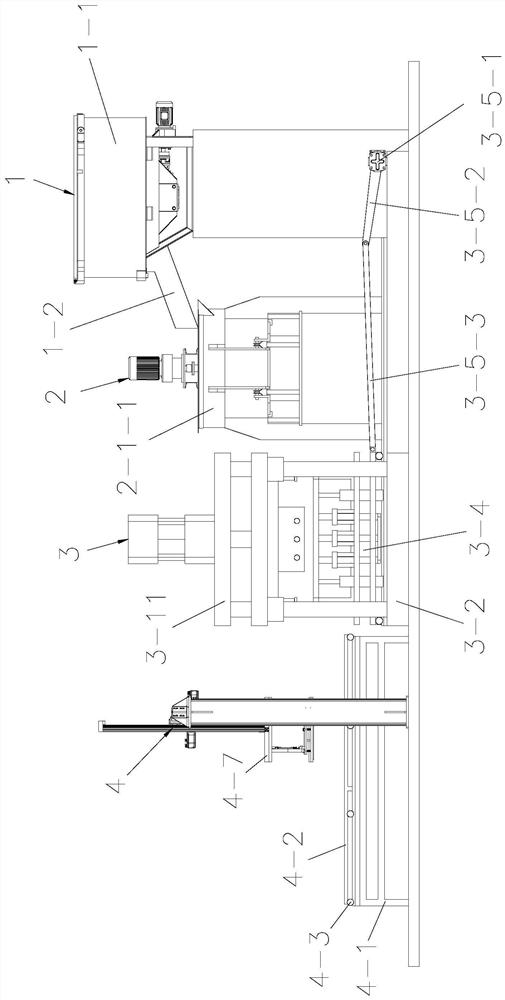

[0074] A cement-based imitation stone type curb stone molding equipment, such as figure 1 As shown, it includes: a mixing mixer 1-1, a mortar mixer 2-1, a quantitative conveying mechanism, a forming device 3, a conveying mechanism and a stacking mechanism, which are arranged in sequence in an assembly line.

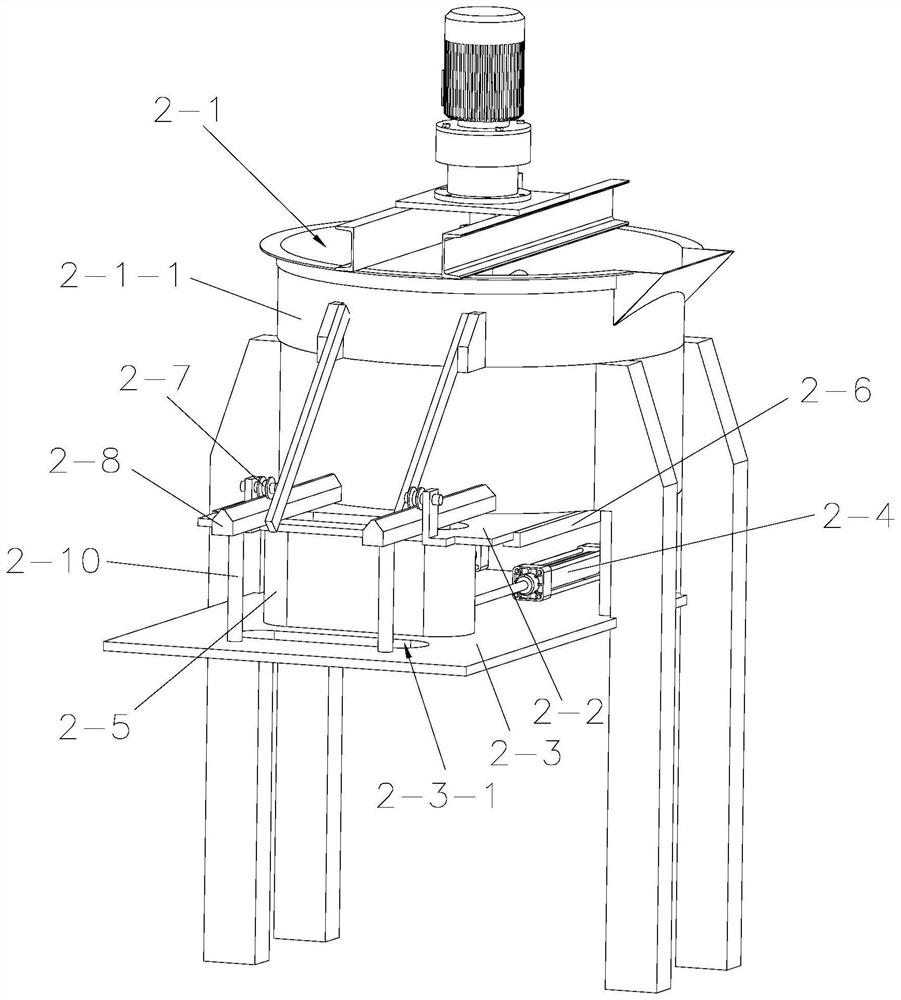

[0075] The bottom of the mixer 1-1 is fixedly installed with a feeding cylinder 1-2, such as figure 2 As shown, the feeding cylinder 1-2 is connected to the mixing cavity of the mixing mixer 1-1. The optional brand of the mixing mixer 1-1 is: Gaohong Construction Machinery, the model is: 350 type vertical mixer, and the optional brand is: Guanghuitong , model: 400L multifunctional mixer; Mortar mixer 2-1 is located just below the discharge end of feeding cylinder 1-2, the optional brand of mortar mixer 2-1 is: Jinchengsheng, model: PZ-7*2 Single-cylinder mortar mixer 2-1; mortar mixer 2-1 includes mixing barrel 2-1-1, such as image 3 As shown, the bottom of the mixing...

Embodiment 3

[0102] Below in conjunction with the molding equipment in embodiment 2, the preparation method of cement-based imitation stone type curb is further elaborated:

[0103] Include the following steps:

[0104] a) Put 14-16% of cement, 26-29% of yellow sand, 37-39% of crushed stone, 11-13% of gypsum, 6-9% of water into mixing mixer 1-1 After fully mixing, the concrete mixed wet material is obtained, and then the concrete mixed wet material is transported to the mortar mixer 2-1 through the feeding cylinder 1-2 for secondary mixing;

[0105]b) When the concrete mixed wet material is stirred for the second time in the mortar mixer 2-1, the first driving mechanism 2-4 drives the feeding cylinder 2-5 to be located directly below the first blanking through hole 2-1-1-1, The moving cylinder 2-5 is completely connected with the first blanking through hole 2-1-1-1, the moving cylinder 2-5 stops moving, and the wet concrete mix passes through the first blanking through hole 2-1-1. -1 fal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com