A high-voltage line maintenance device

A high-voltage line, mounting plate technology, applied in the field of power grid, can solve problems such as broken wires, grid system failures, cracks and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

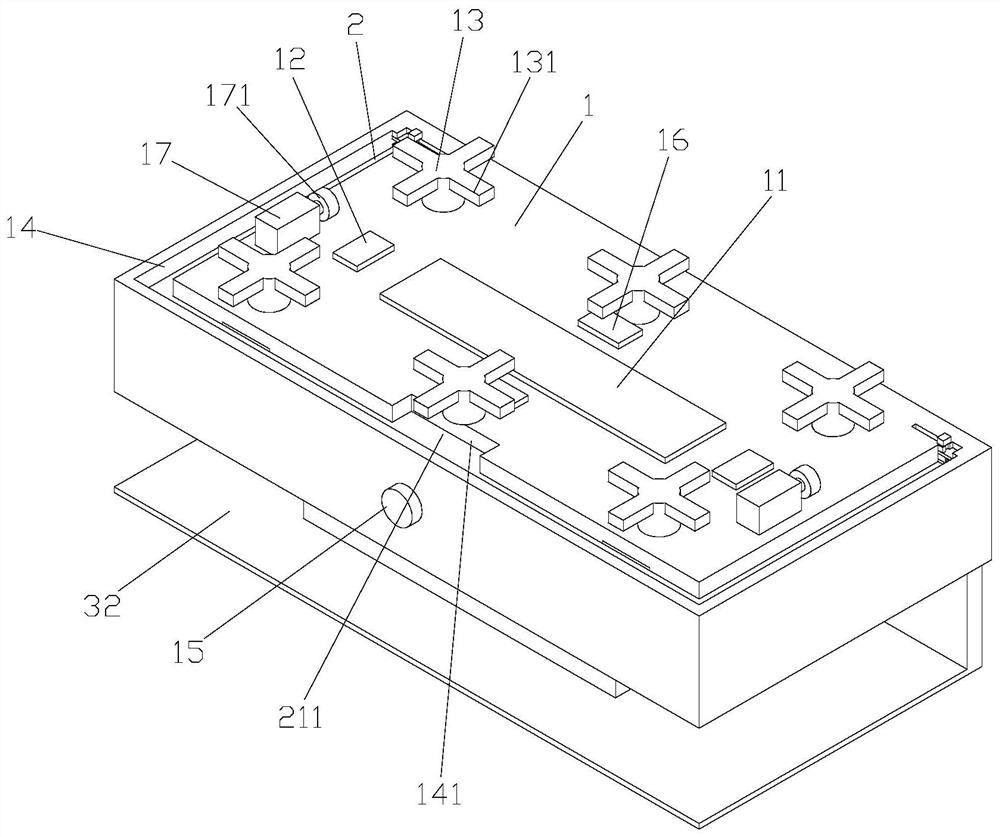

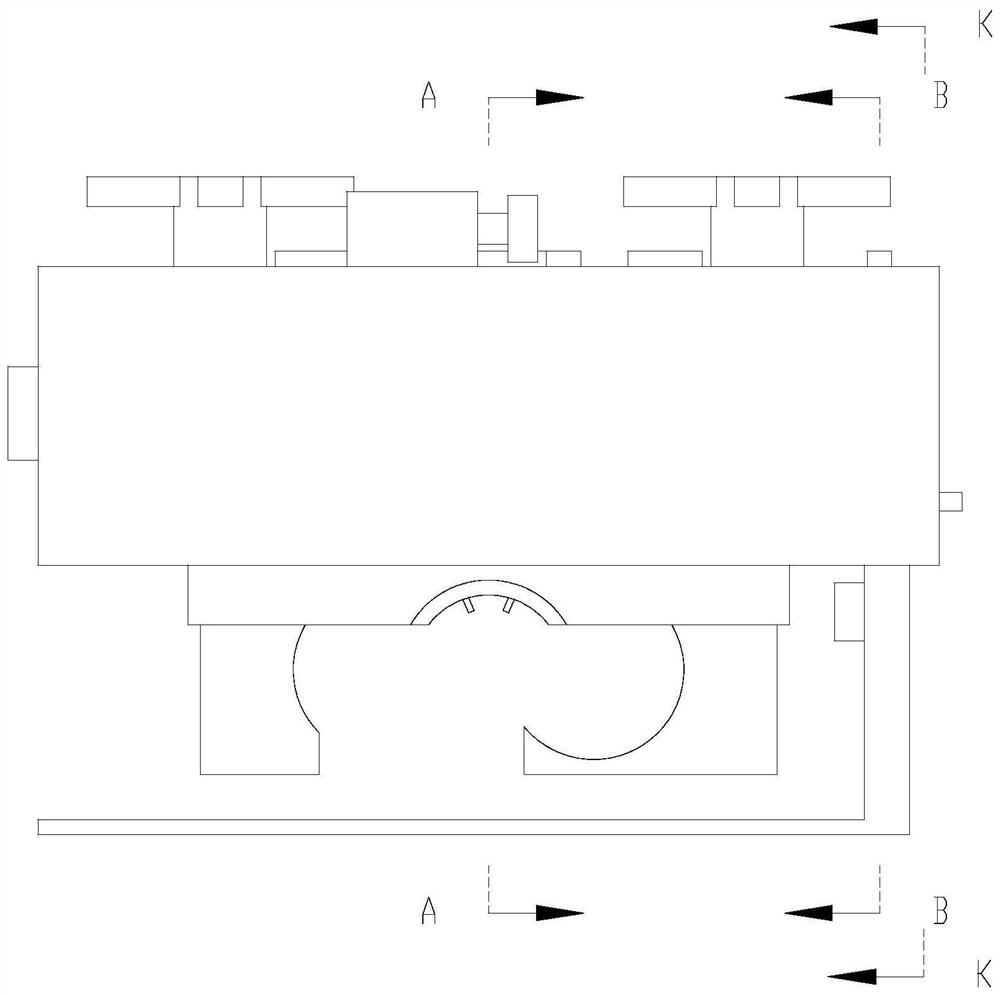

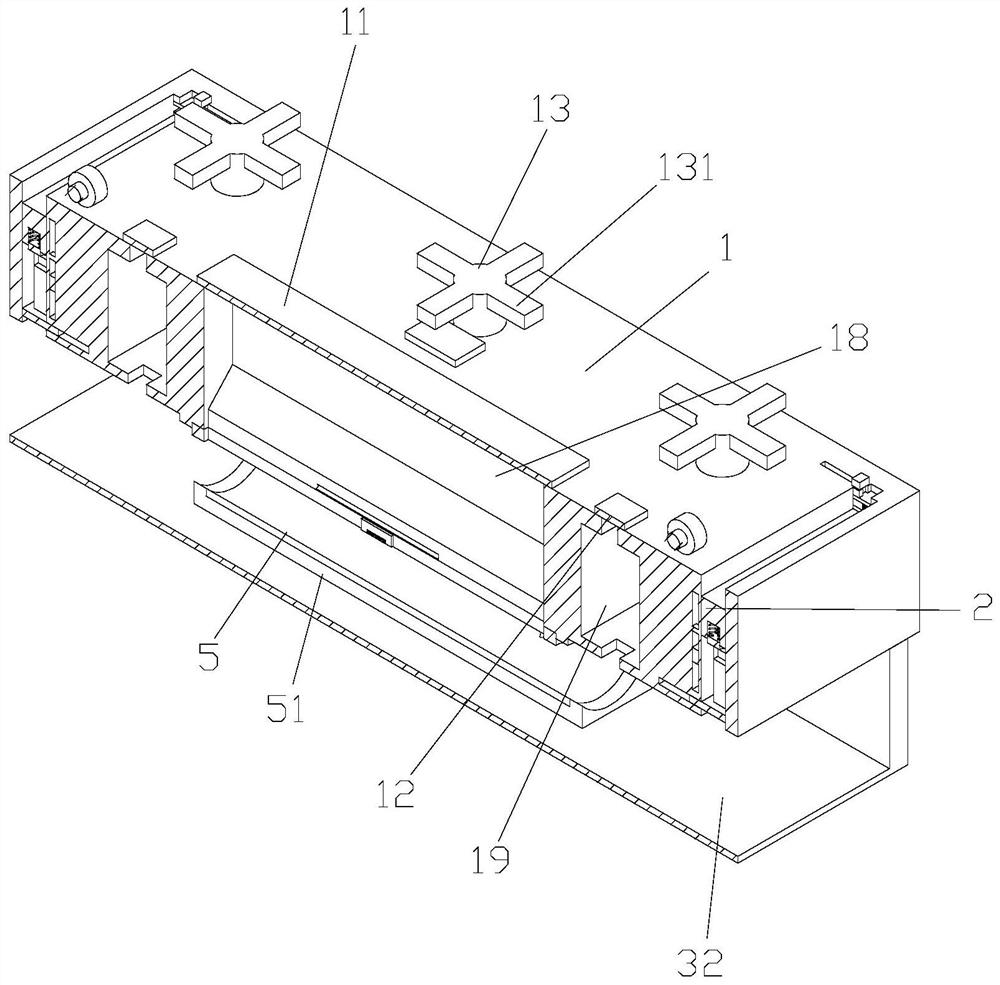

[0038] Such as Figure 1-23As shown, a high-voltage line maintenance device includes a mounting plate 1, a plurality of transmission shafts 13 are arranged on the installation plate 1, and a plurality of fan blades 131 are arranged on the transmission shaft 13, and the cooperation between the transmission shaft and the fan blades and In the prior art, the propeller structure of the unmanned aerial vehicle is the same, and the third drive motor for driving the transmission shaft to rotate is provided on the mounting plate, and the mounting plate can be driven to rise when the fan blade rotates; the side wall of the mounting plate 1 is provided with The first camera 15, the first camera is located on the side wall of the mounting plate, to avoid other parts such as fan blades from blocking the camera; the bottom of the mounting plate 1 is provided with a welding torch 471; the bottom of the mounting plate 1 is provided with a first movable groove , the first movable groove is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com