Instrument device for monitoring molten iron leakage of casting mold in vacuum suction casting chamber

A technology of vacuum suction casting and molten iron leakage, which is applied in the field of instruments and devices for monitoring molten iron leakage of casting molds in vacuum suction casting chambers. The effect of destroying the expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

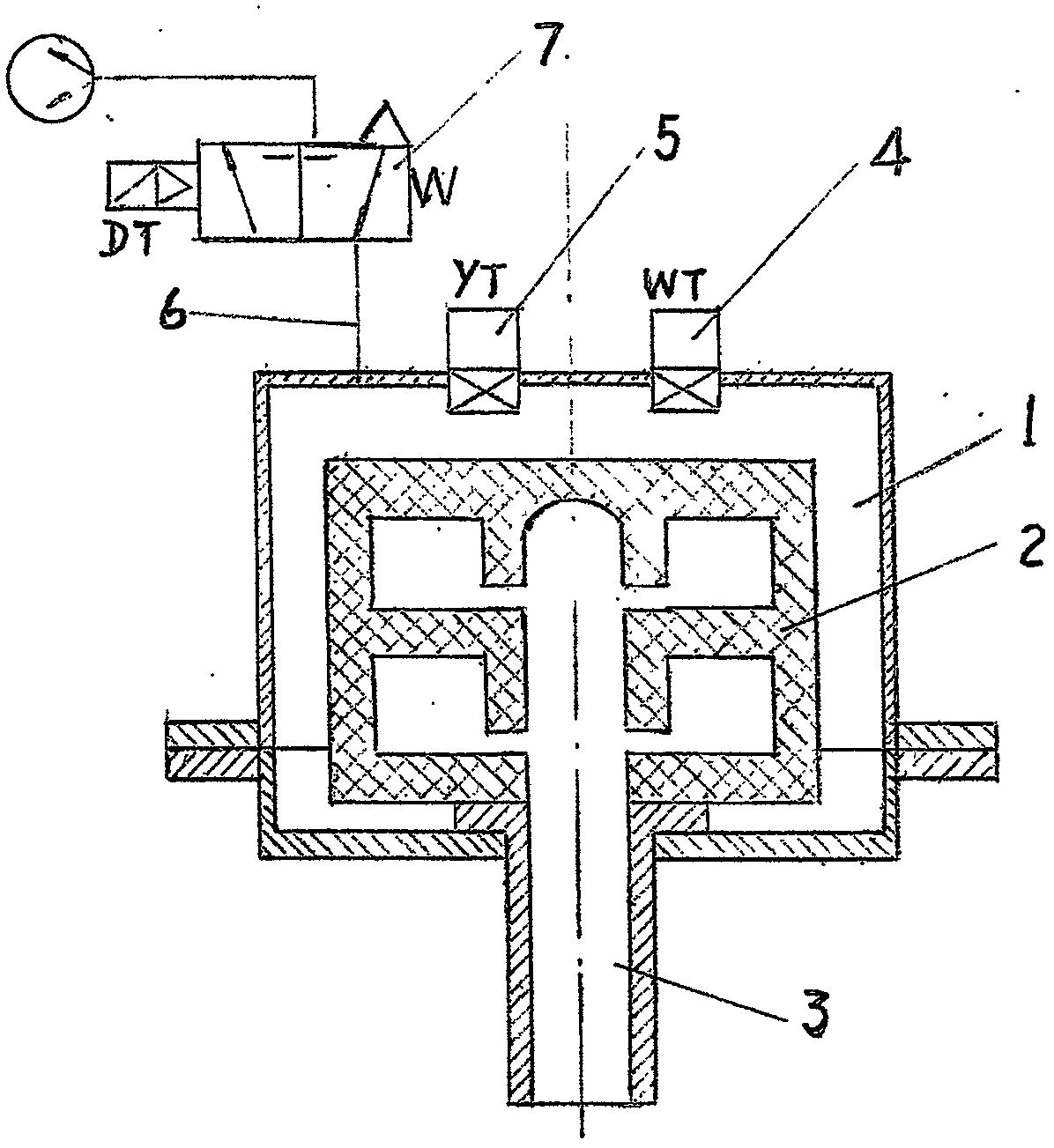

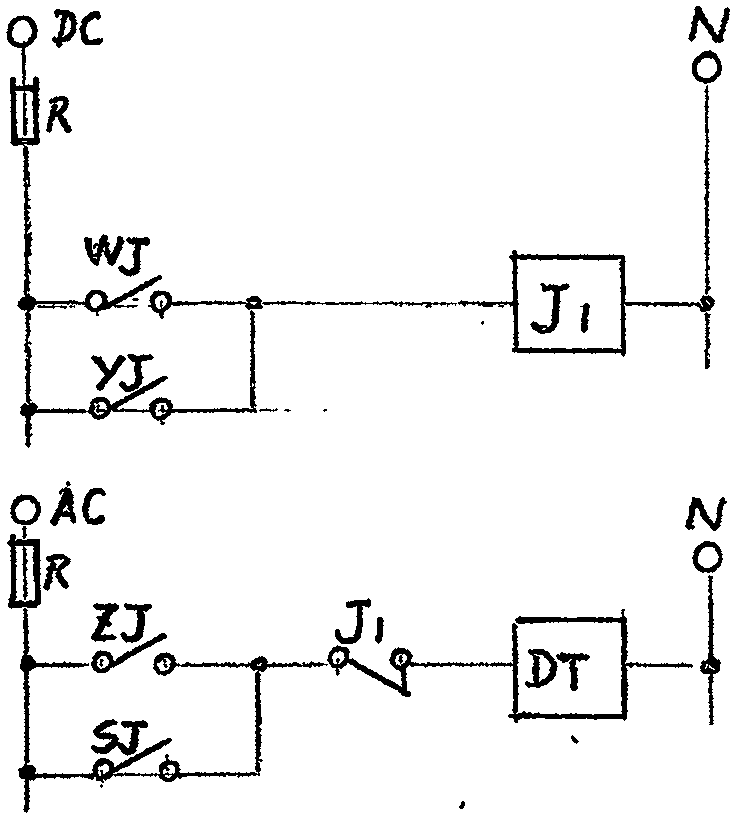

[0010] The casting mold 2 is installed on the mounting seat of the suction casting chamber 1, the liquid riser 3 is installed on the bottom surface of the suction casting chamber 1 at the lower part of the casting mold 2, and the temperature sensor probe 4 and the pressure sensor probe 5 are installed on the top of the suction casting chamber 1, When the temperature sensor probe 4 or the pressure sensor probe 5 has a signal, the vacuum air supply valve 7 will immediately lose power and change direction, open the air supply channel, release the vacuum, and stop suction casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com