Acid removing device and acid removing system

A heating device and condensation device technology, applied in the field of analytical chemistry, can solve the problems of sample loss, complicated operation, pollution, etc., and achieve the effects of strong versatility, loss reduction, and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

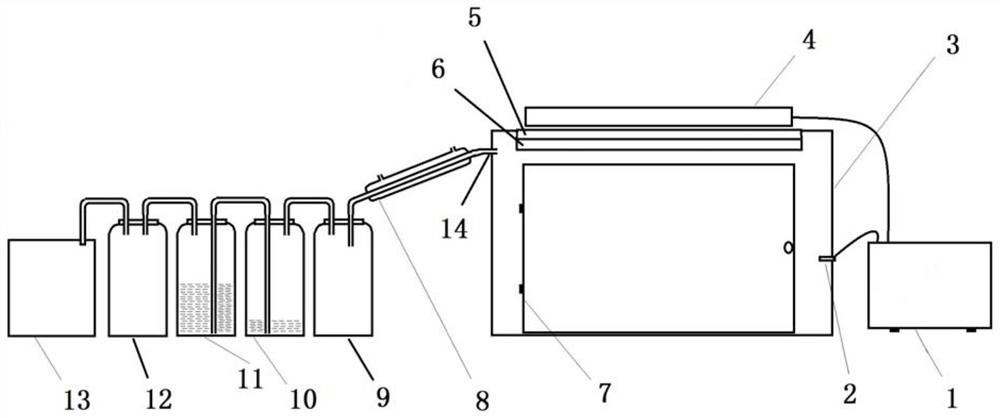

[0047] This embodiment provides an acid catching device, such as figure 1 As shown, it includes a box body 3, the box body 3 is provided with an acid gas outlet 14, a transparent glass window 5 is arranged on the top of the box body 3, and an infrared heating device 4 is arranged outside the box body 3. , and is located on the upper part of the transparent glass window 5 , so that the infrared light emitted by the infrared heating device 4 enters the inside of the box 3 through the transparent glass window 5 to heat the acid-containing solution inside the box 3 .

[0048] Further, it also includes an acid-resistant coating 6, which is arranged on the lower surface of the transparent glass, and infrared light can enter the box 3 through the acid-resistant coating 6; and a temperature control device 1, which is arranged on the box. 3. In addition, the temperature sensing device 2 is arranged on the box body 3 or inside the box body 3, and the temperature control device 1 is resp...

Embodiment 2

[0050] This embodiment provides an acid rushing system, such as figure 1 As shown, including the acid rushing device described in Embodiment 1, and also including the acid gas condensing device 8, the acid gas recovery device and the vacuuming device 13 that are connected in sequence, and the air inlet of the acid gas condensing device 8 is connected with the described acid gas condensing device 8. The acid gas outlet 14 of the tank 3 is communicated. Further, the acid gas recovery device includes a liquid acid collection device 9, an acid gas absorption device and an anti-suckback device 12 that are communicated successively, and the inlet of the liquid acid collection device 9 and the outlet of the acid gas condensation device 8. The gas port is connected, and the gas outlet of the anti-suckback device 12 is communicated with the vacuum device 13; the acid gas absorption device includes a first acid gas absorption bottle 10 and a second acid gas absorption bottle 11, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com