a stepped energy dissipator

An energy dissipator and ladder technology, applied in marine engineering, water conservancy engineering, construction, etc., can solve the problems of single-width flow restriction and high requirements for initial aeration position, reduce kinetic energy, change the size of eddy current, and eliminate water flow energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, no longer described in detail here.

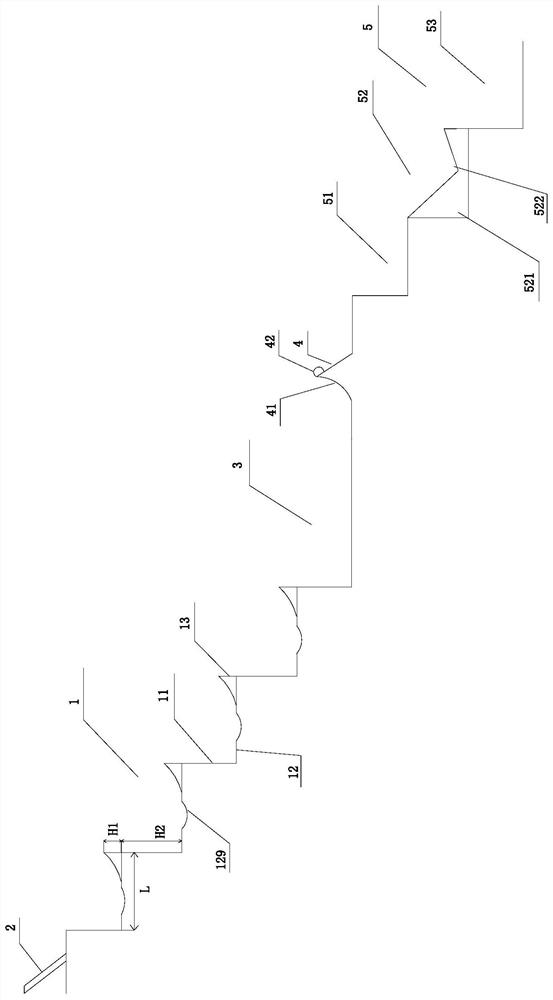

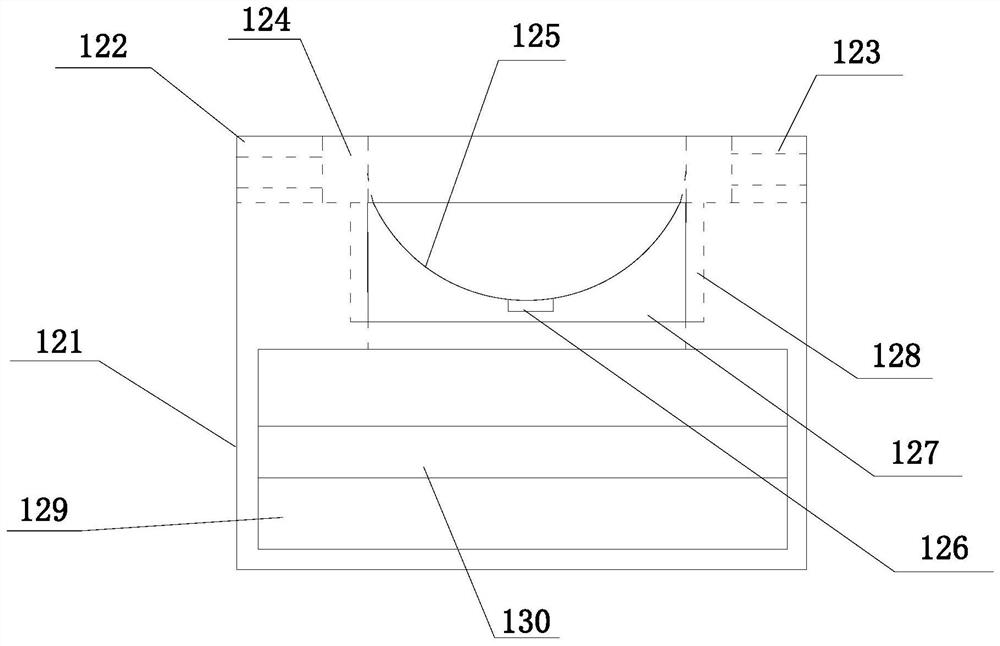

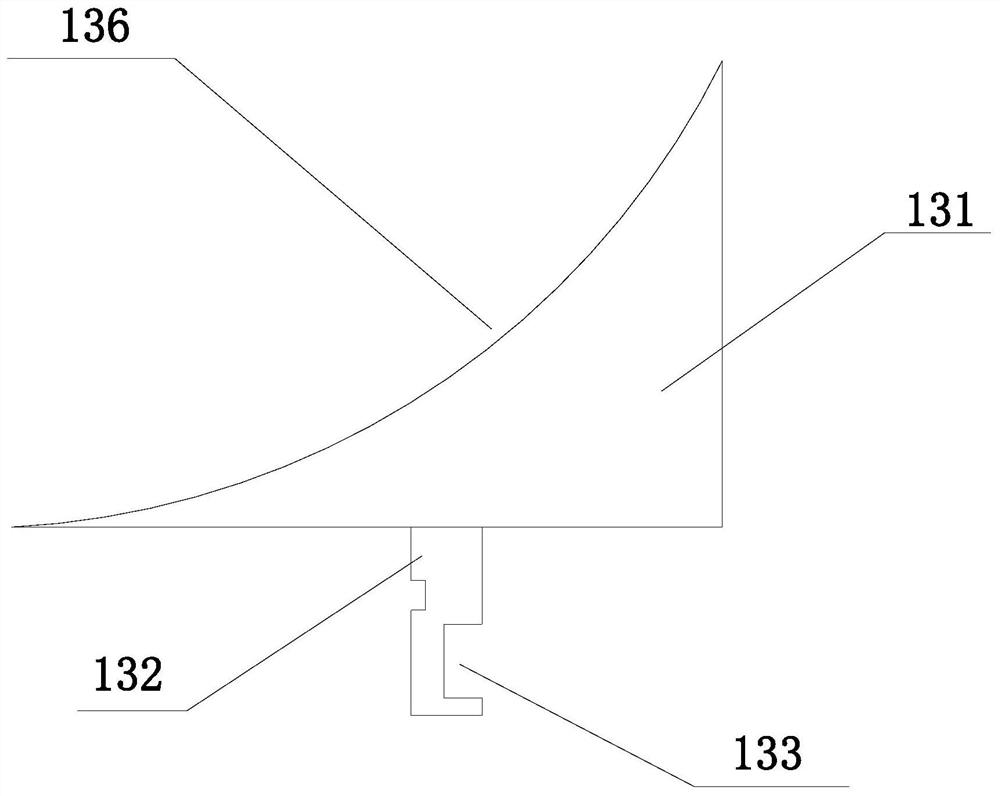

[0017] refer to Figure 1-5 A specific embodiment of the present invention sequentially includes a first multi-level ladder 1, a stilling pool 3, a triangular prism stilling sill 4 and a second multi-level ladder 5 along the water flow direction, and the water flow upstream of the first multi-level ladder 1 is fixed There is an aeration device 2, and the first multi-level ladder 1 includes several end-to-end connecting horizontal ladders 12 and vertical ladders 11, the horizontal ladders 12 are movably connected with a stagnation block 13, and the horizontal ladders 12 are provided with a first arc-shaped groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com