Automatic splicing device for broken yarns

A wire connector and automatic technology, which is applied in jointing devices, textiles, papermaking, spinning machines, etc., can solve problems such as inconvenient handling and carrying, complex structure of wiring devices, and broken spinning threads, etc., to achieve convenient wiring and operation Simple, convenient and portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

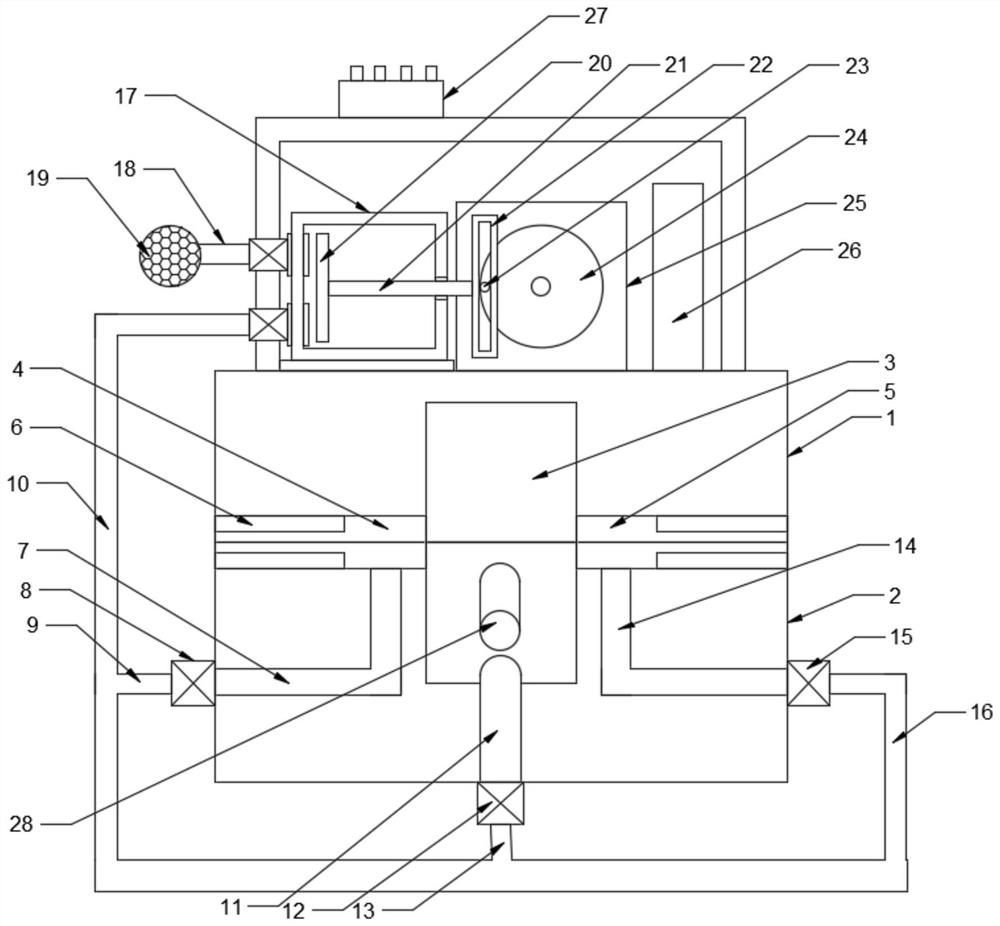

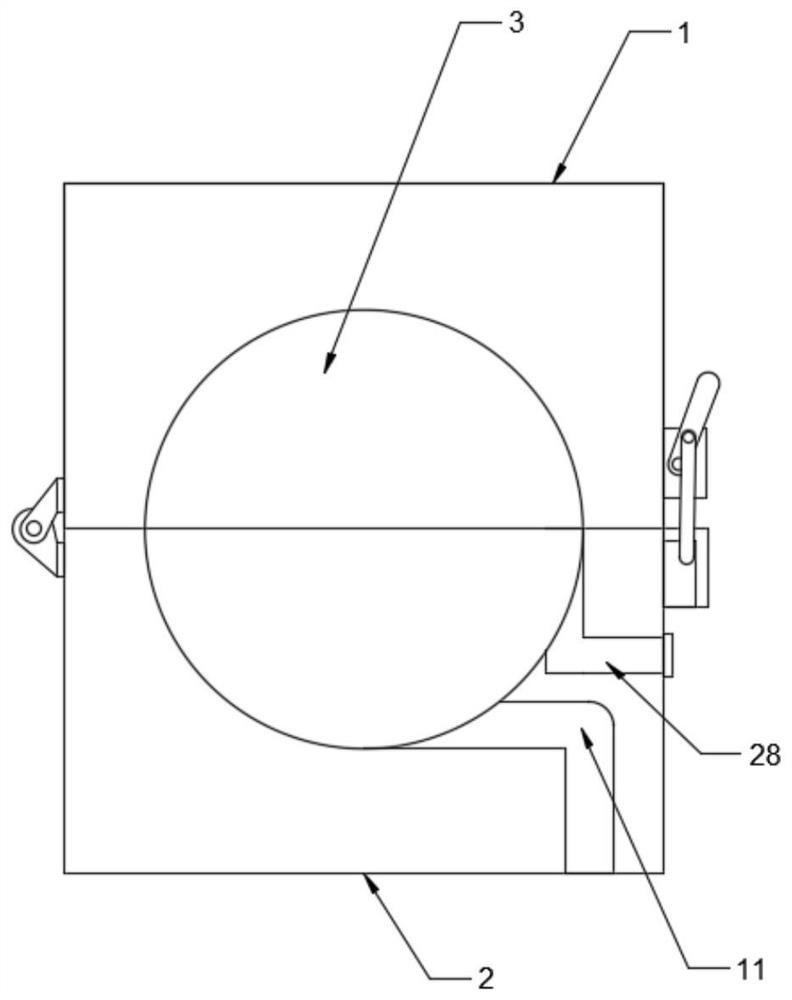

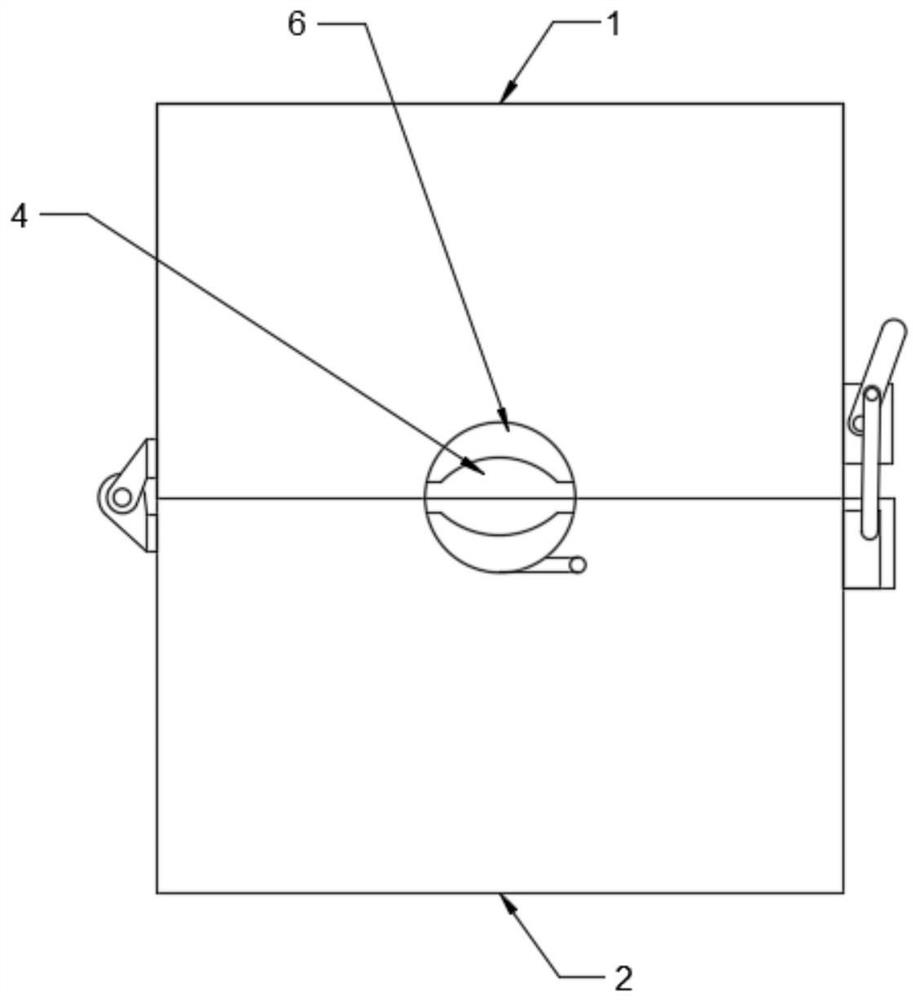

[0020] see Figure 1-4 , in an embodiment of the present invention, an automatic wire breaker, including a junction box; It is fixedly connected by a lock; a columnar spinning cavity 3 is formed between the upper box body 1 and the lower box body 2, the left side of the spinning cavity 3 is connected with a left clamping channel 4, and the right side of the spinning cavity 3 is connected There is a right clamping channel 5, a rubber gasket 6 is bonded in the left clamping channel 4 and the right clamping channel 5, which is convenient for squeezing and clamping the spinning thread; specifically, when the spinning thread breaks, open the upper Box body 1, place the broken part of the broken spinning thread in the spinning chamber 3, nest the outer ends of the spinning thread in the left clamping channel 4 and the right clamping channel 5 respectively, close the upper box body 1 , lock the lock.

[0021] The lower part of the spinning chamber 3 is connected with a central air ...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that in order to fully disperse the spun yarn into fiber bundles, the inside of the left clamping channel 4 is tangentially connected with a left air inlet channel 7, and the left air inlet channel 7 is connected with a first branch pipe 9. The first branch pipe 9 communicates with the intake main pipe 10, and the first solenoid valve 8 is provided at the connection between the left intake passage 7 and the first branch pipe 9, and the first solenoid valve 8 is connected with the switch plate 27 to facilitate the opening of the first solenoid valve 8. Make the air flow enter the left clamping channel 4, and swirl and blow off the spinning yarn, so that the spinning yarn is dispersed into scattered fiber bundles; similarly, the inside of the right clamping channel 5 is tangentially connected to the right air inlet channel 14. The right air intake channel 14 is connected with a third branch pipe 16, and the third b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap