Integrated uniform temperature plate and manufacturing method thereof

A vapor chamber and one-piece technology, applied in the field of heat dissipation technology, can solve the problems of difficult processing, cumbersome welding and sealing process, peeling or falling off of the upper shell and the lower shell, etc., to control the leakage problem, solve the problem of easy peeling or Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and illustration, and are not intended to limit the present invention.

[0035] see Figure 6 As shown, the present invention provides a kind of integral type vapor chamber manufacturing method, and its method step comprises:

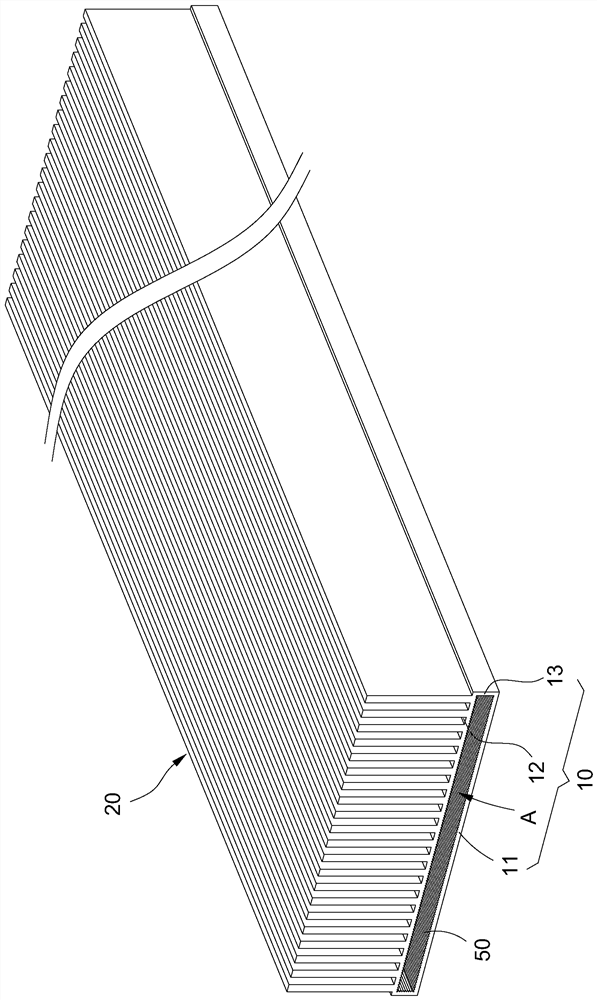

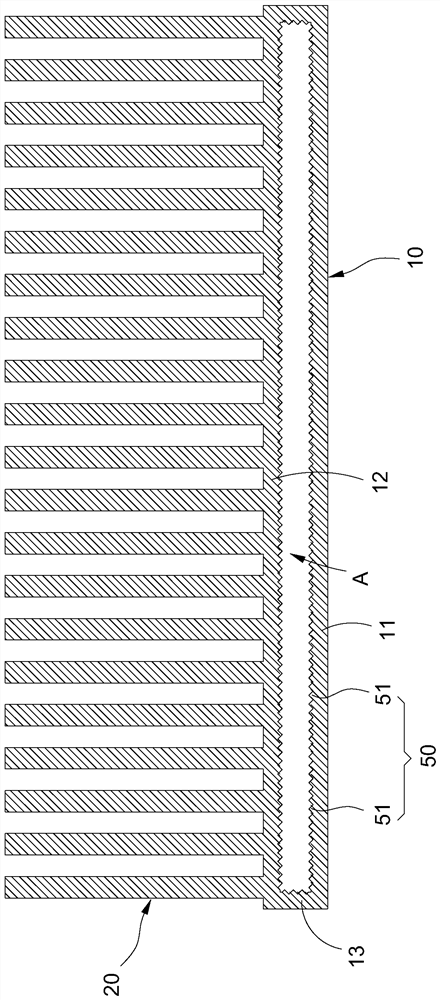

[0036] a) forming a housing base material and a plurality of cooling fin materials connected to the housing base material by drawing or extruding, and forming a cavity A inside the housing base material;

[0037] b) Carrying out a segmental cutting process on the housing base material and each of the cooling fin materials, and forming an opening at the first and last ends of the cavity A;

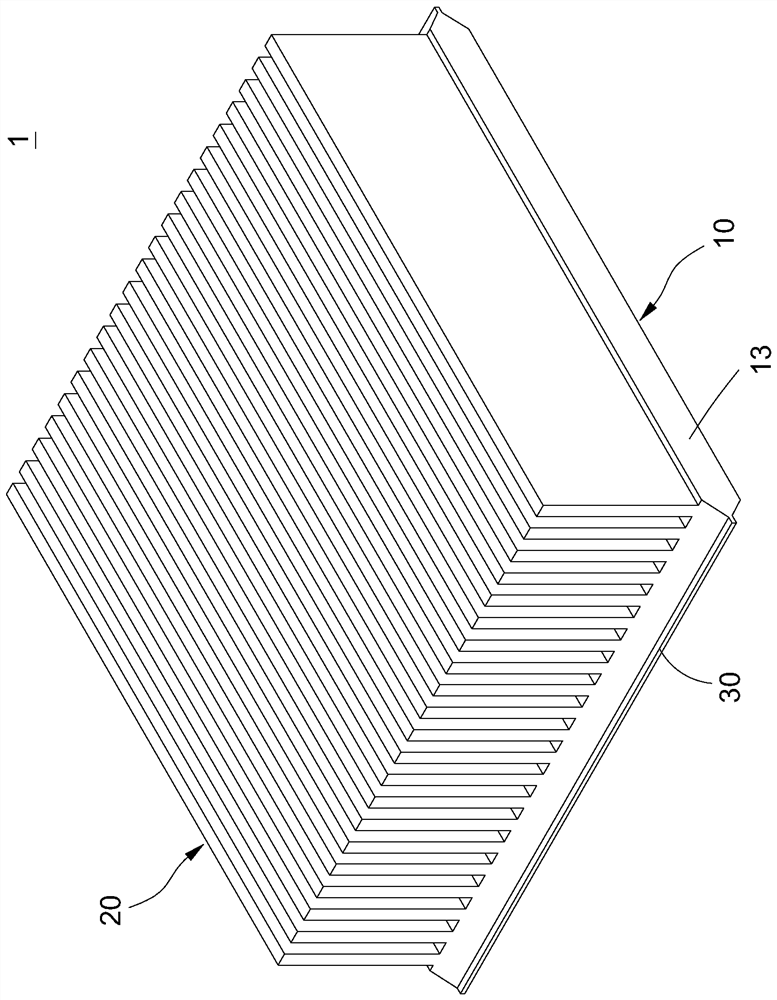

[0038] c) Perform a press-fit sealing process on each of the segmented openings, and form a sealing portion 30 respectively; and

[0039] d) Filling a working fluid 40 into the cavity A and applying a degassin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com