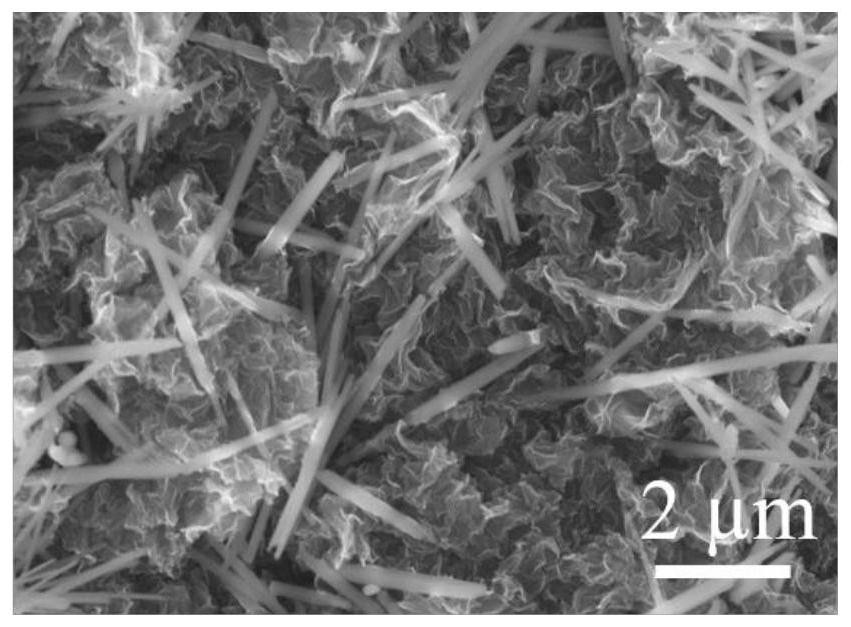

A kind of preparation method of graphene and polyaniline composite fiber electrode material

An electrode material and composite fiber technology, which is applied in the field of composite electrode material preparation, can solve the problems of easy dense stacking of graphene sheets, easy aggregation of polyaniline, etc., and achieves easy large-scale preparation, low cost, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of preparation method of graphene and polyaniline composite fiber electrode material comprises the following steps:

[0034] (1) Polyaniline is cleaned with deionized water and dried to obtain product A; the polyaniline is prepared by rapid polymerization;

[0035] (2) Add 0.006g of product A into 10mL of organic solvent; the organic solvent is N,N-dimethylformamide, ultrasonically disperse for 20min, and magnetically stir for 20min;

[0036] (3) Add 0.6g of graphene oxide into product B, ultrasonically disperse at 5°C for 2h, and then add 10mL of deionized water dropwise under the condition of magnetic stirring to obtain graphene oxide and polyaniline composite gel, namely C product;

[0037] (4) Product C is prepared into fibers by wet spinning technology, and after hydroiodic acid reduction, vacuum drying at 50°C for 26 hours to obtain fiber electrode materials, the electrode materials are made of 1M polyvinyl alcohol (PVA) and sulfuric acid Th...

Embodiment 2

[0038] Embodiment 2: a kind of preparation method of graphene and polyaniline composite electrode material comprises the following steps:

[0039] (1) polyaniline is cleaned with deionized water and dried to obtain product A; the polyaniline is prepared by rapid polymerization;

[0040](2) Add 0.012g of product A into 10mL of organic solvent; the organic solvent is N,N-dimethylformamide, ultrasonically disperse for 30min, and magnetically stir for 40min;

[0041] (3) Add 0.6 g of graphene oxide into product B, ultrasonically disperse at 5°C for 1 h, and then add 10 mL of deionized water dropwise under the condition of magnetic stirring to obtain a composite gel of graphene oxide and polyaniline, namely C product;

[0042] (4) Prepare product C into fibers by wet spinning technology, reduce with hydroiodic acid, and dry in vacuum at 60°C for 24 hours to obtain the electrode material. The electrode material is made of a gel composed of 1M polyvinyl alcohol and sulfuric acid. E...

Embodiment 3

[0043] Embodiment 3: a kind of preparation method of graphene and polyaniline composite fiber electrode material comprises the following steps:

[0044] (1) Polyaniline is cleaned with deionized water and dried to obtain product A; the polyaniline is prepared by rapid polymerization;

[0045] (2) Add 0.03g of product A into 10mL of organic solvent; the organic solvent is N,N-dimethylformamide, ultrasonically disperse for 30min, and magnetically stir for 40min;

[0046] (3) Add 0.6g of graphene oxide into product B, ultrasonically disperse at -3°C for 2h, and then add 10mL of deionized water dropwise under the condition of magnetic stirring to obtain graphene oxide and polyaniline composite gel, i.e. product C;

[0047] (4) Prepare product C into fibers by wet spinning technology, reduce with hydroiodic acid, and dry in vacuum at 70°C for 22 hours to obtain the electrode material. The electrode material is made of a gel composed of 1M polyvinyl alcohol and sulfuric acid. Elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com