Reaction device for pile foundation pullout static load test

A reaction device and static load test technology, which is applied in the direction of basic structure test, measuring device, basic structure engineering, etc., can solve the problems of weld damage, time-consuming and labor-intensive problems, reduce the possibility of fracture, improve test efficiency, The effect of reducing the possibility of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

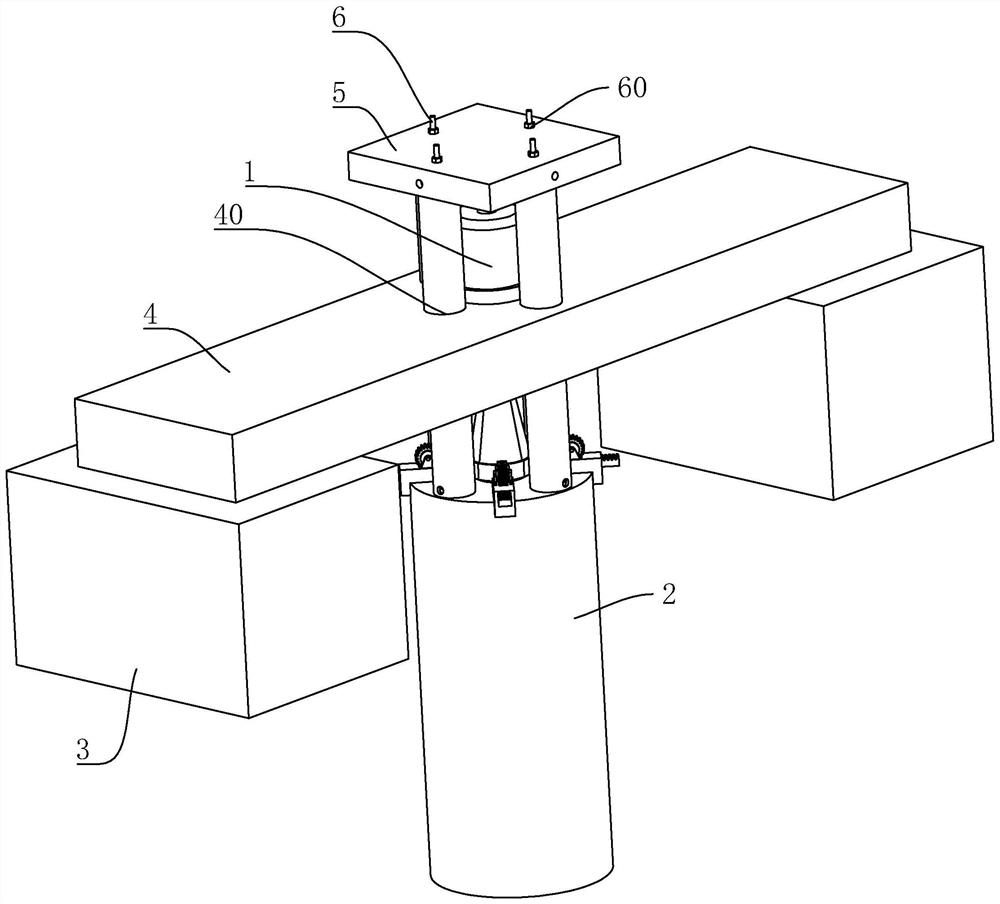

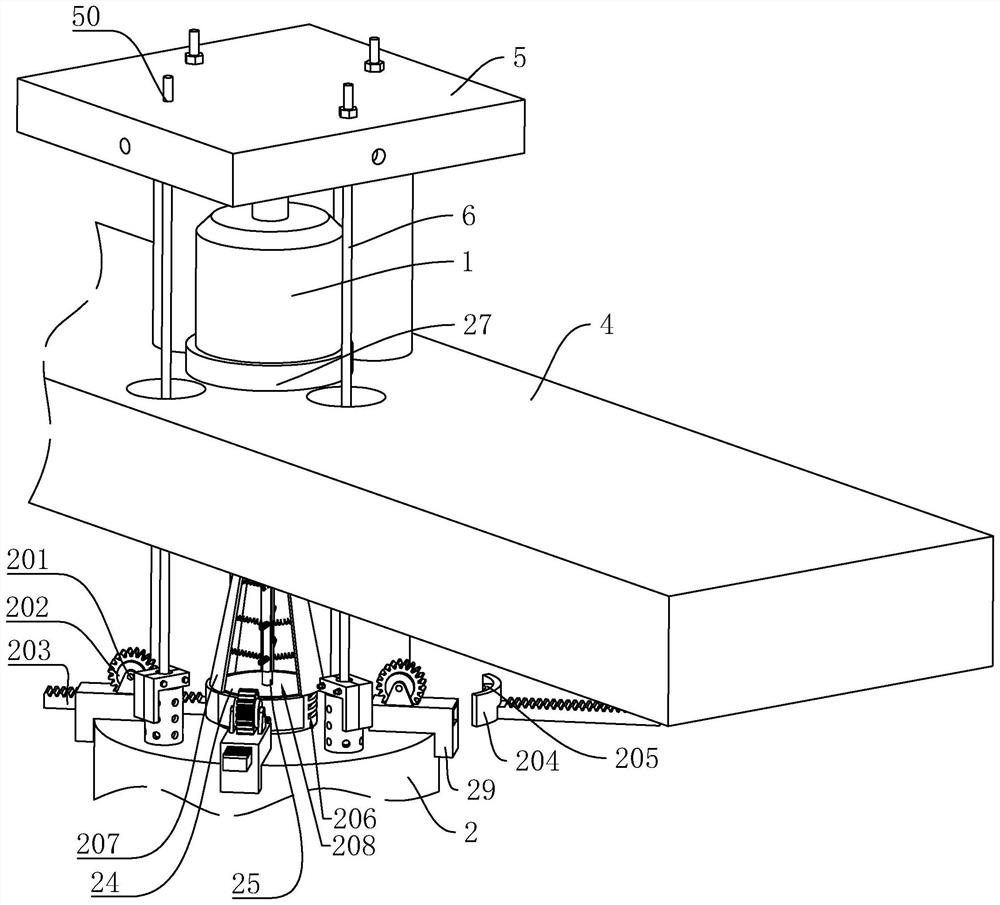

[0044] refer to figure 1 and figure 2 , a kind of counter force device for pile foundation anti-pull static load test, it comprises two support pads 3 that are arranged on the ground and are respectively located at the two sides of pile foundation 2, the crossbeam 4 that is arranged on two support pads 3, The jack 1 arranged on the beam 4 and the top plate 5 arranged on the bracket of the jack 1, the side of the top plate 5 near the jack 1 is provided with a groove 28 for the jack 1 bracket to extend into, on the top plate 5 and along the groove The axis of 28 is evenly distributed with several limit holes 50 (refer to image 3 ), the top plate 5 is provided with several connecting rods 6 passing through the limiting holes 50, the diameter of the connecting rods 6 is equal to the diameter of the limiting holes 50, and one end of the connecting rods 6 passing through the limiting holes 50 is threadedly connected with a connecting nut 60 , The beam 4 is provided with a mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com