A method for automatic tool avoidance of clamping mechanism

A clamping mechanism and automatic avoidance technology, used in clamping, manufacturing tools, metal processing mechanical parts, etc., to achieve the effect of solving motion interference, high reliability and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

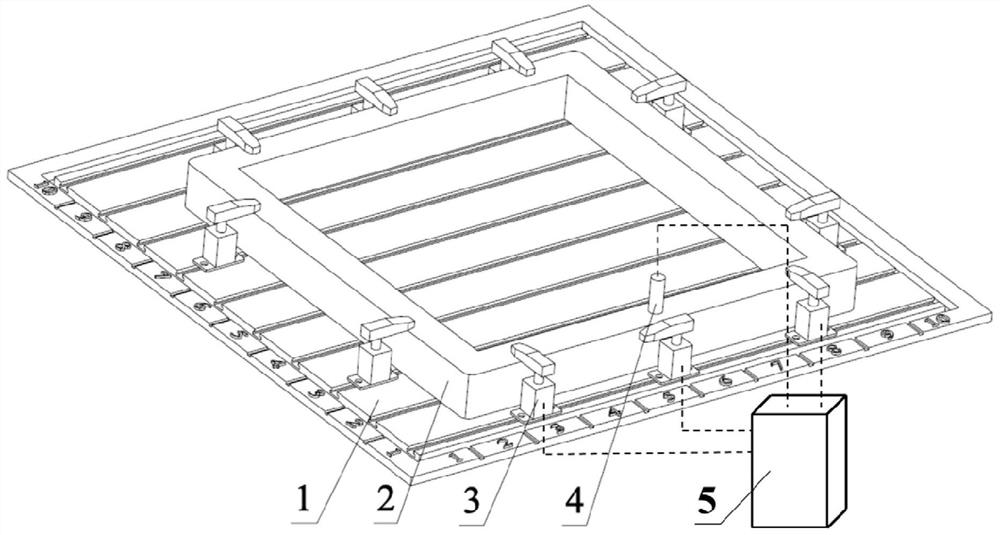

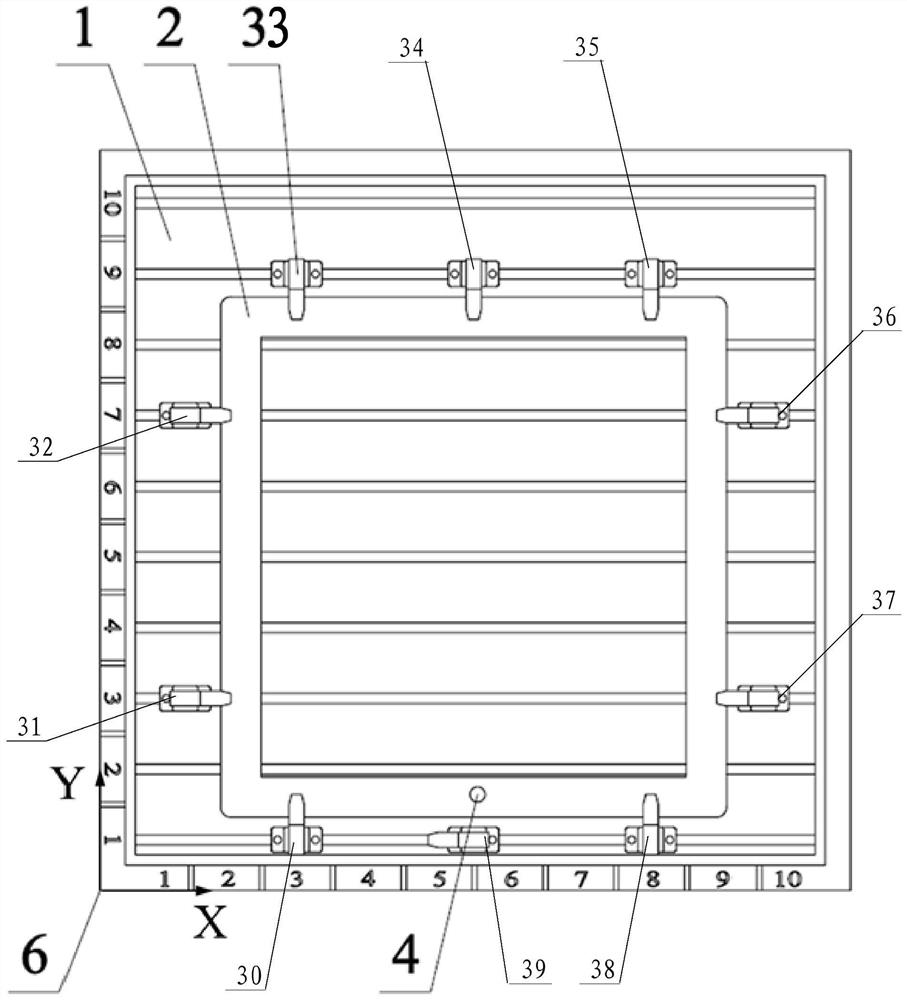

[0031] The first step is to build a workpiece clamping control system with automatic tool avoidance function:

[0032] Measure the length and width of the working platform 1 of the CNC machine tool, which are 2500mm and 2500mm respectively. Carry out area division along the length and width directions of the CNC machine tool working platform 1, among which 10 areas are divided along the length direction, each area is 250mm, and the serial number (1~10) is marked; according to the layout of the trapezoidal groove, the width direction is divided into 10 areas, Each area is 250mm, and the serial number (1~10) is marked. The sum of the divided sub-regions has covered the entire working platform 1 of the CNC machine tool. Establish the CNC machine tool work platform coordinate system 6 under the CNC machine tool work platform 1, and record the length and width range of each sub-region under the coordinate system, for example: the range of the area (1, 2) under the CNC machine tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com