Coating machine for pharmacy

A coating machine and coating technology are applied in the direction of making medicines into special physical or ingestible devices, coatings, etc., which can solve the problems of continuous processing, limited processing efficiency, and many processes, and achieve the goal of coating Good effect, uniform distribution, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

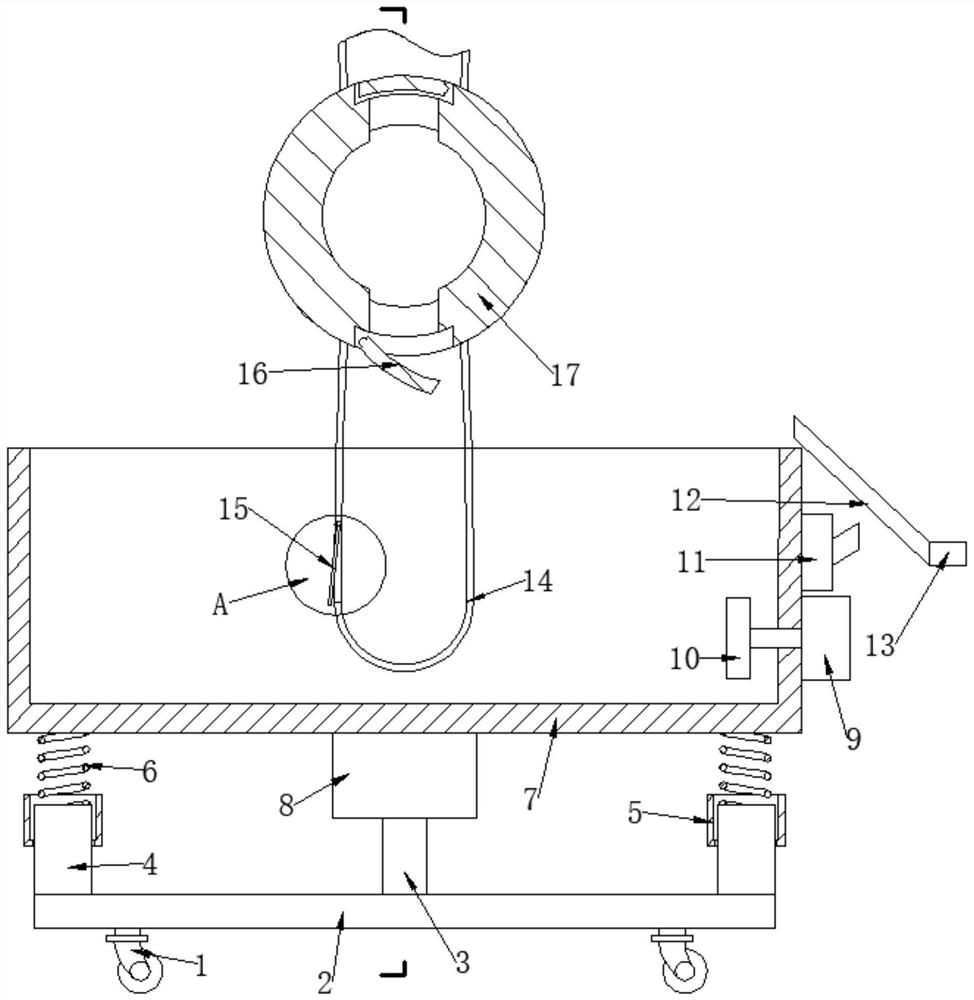

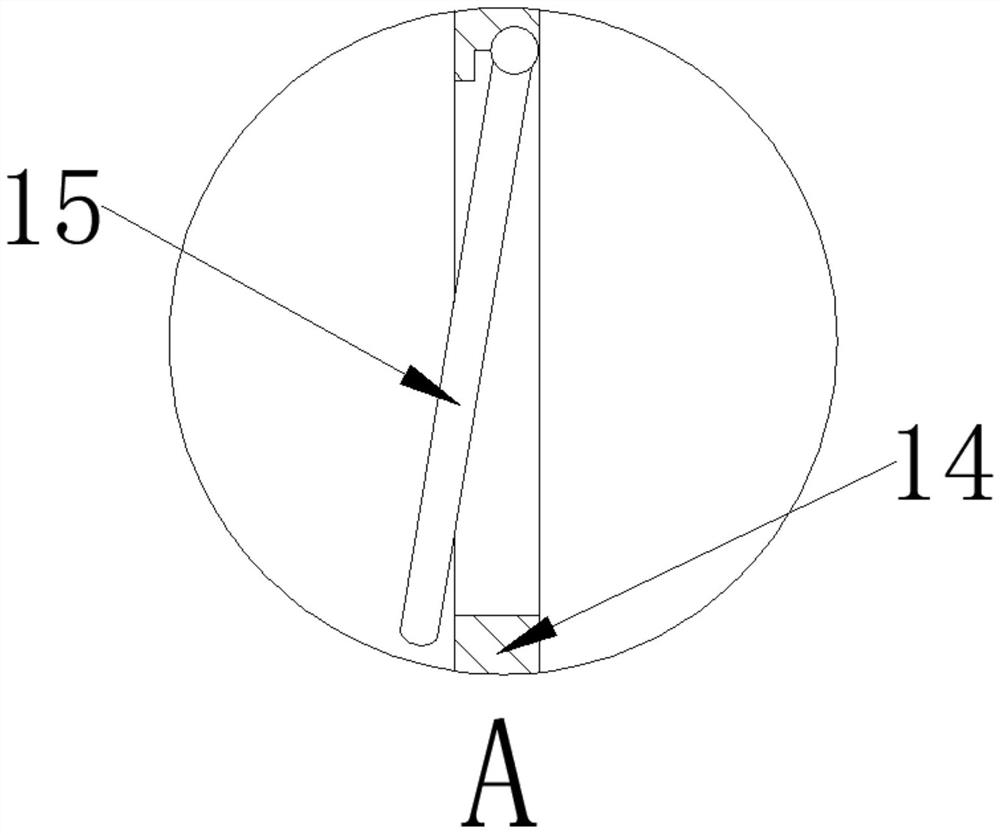

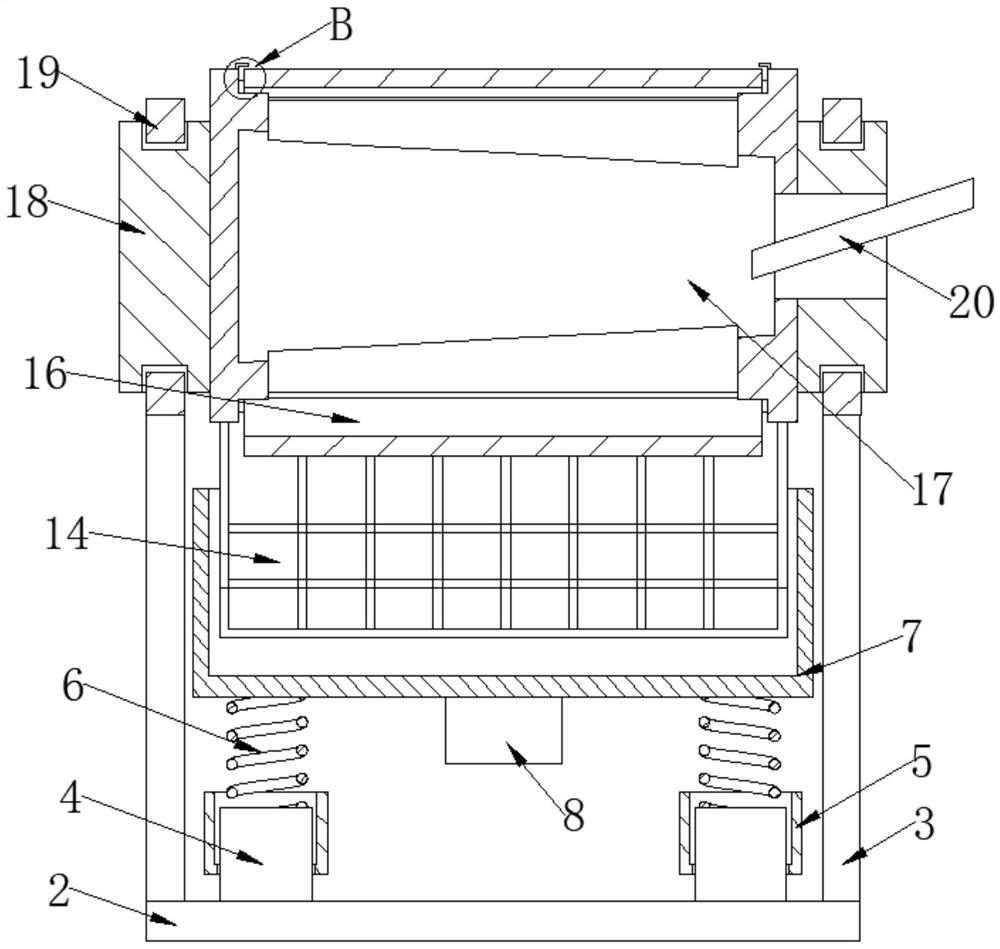

[0029] see Figure 1-5 , this embodiment provides a pharmaceutical coating machine, including a feed structure 20 for undertaking the previous process and a conveying mechanism 13 for connecting the next process, and is also provided with a fixed support frame and a coating actuator,

[0030] The fixed support structure includes a support base plate 2, on which the support base plate 2 is fixedly provided with a support column 3 and a fixed column 4, and the end of the support column 3 away from the support base plate 2 is fixedly connected with a mounting ring 19, the fixed A spring 6 is fixedly connected to one end of the column 4 away from the support base plate 2;

[0031] One end of the spring 6 away from the fixed column 4 is fixedly connected with a coating pool 7 for containing the coating liquid, and a heat supply machine for heating is arranged below the coating pool 7 to prevent the coating liquid from solidifying. Described coating pool 7 sides are provided with a...

Embodiment 2

[0041] On the basis of Example 1, the support column 3 is provided with a lifting mechanism, so that the height of the coating actuator can be adjusted, making it more convenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com