A kind of preparation method of graphite material for oxygen, nitrogen and hydrogen analysis instrument

A technology for analysis instruments and graphite materials, which is applied in the field of preparation of graphite materials for oxygen, nitrogen and hydrogen analysis instruments, can solve problems such as difficult to meet, and achieve the effects of preventing product adhesion, increasing density and strength, and preventing product cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

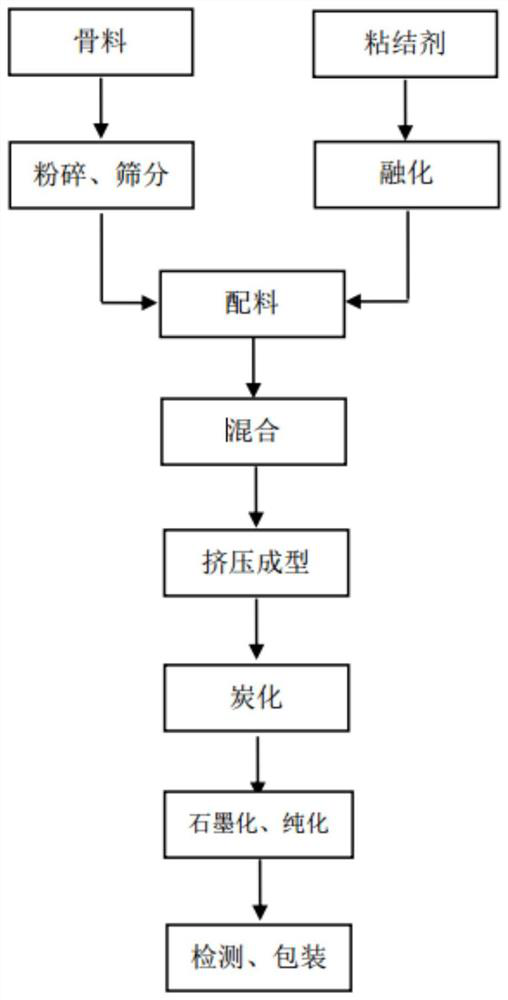

[0024] In the present embodiment, the main performance indicators of aggregate microcrystal graphite and binder coal aspage are as follows: microcrystalline graphite: a gray is 0.32%; nitrogen content is 0.013%; graphite is 93.3%; coal asphalt: softening point 85 ° C; The toluene is not soluble 22.4%; the quinoline is not soluble 7.1%; figure 1 The production process of this embodiment is carried out in the following steps:

[0025] Step 1: The dried microcrystalline graphite was pulverized through 0.15 m sieve, with a greater than 0.075 mm component to 31%, as aggregate spare; the coal asphalt was heated to 160 ° C.

[0026] Step 2: According to 76% of microcrystalline graphite, the weight of the coal asphalt is weighed;

[0027] Step 3: Always referring to a fine microcrystalline graphite in the mixed apparatus, then add a sufficiently molten coal seam, mixed 40 min at 160 ° C to give a paste;

[0028] Step 4: Place the paste in the extruded molding machine, extruded under a 30 ...

Embodiment 2

[0061] In the present embodiment, the main performance indicators of aggregate microcrystal graphite and binder coal asphalt: microcrystalline graphite: 0.32% ash; nitrogen content 0.013%; graphite level 93.3%; warm coal asphalt: Softening point 85 ° C The toluene is less than 22.4%; the quinoline is not soluble 7.1%; for specific process flows figure 1 The production process of this embodiment is carried out in the following steps:

[0062] Step 1: The dried microcrystalline graphite was pulverized through 0.15 m sieve, wherein greater than 0.075 mm component proportional to 39%, as aggregate spare, heat the coal asphalt to 165 ° C fully melted;

[0063] Step 2: According to 78% microcrystalline graphite, 22% of the coal asphalt is weighed;

[0064] Step 3: The microcrystalline graphite that is known under normal pressure is put into the mixed apparatus, then the sufficiently molten coal seam is added, mixed at 165 ° C for 30 min to give a paste;

[0065] Step 4: Place the paste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com