Multi-channel automatic purification device

An automatic purification and multi-channel technology, applied in chemical instruments and methods, preparation of test samples, separation methods, etc., can solve the problems of high production cost, complexity, difficult structure, etc., and achieve low production cost, simple device, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention is described in detail below in conjunction with examples, but the present invention is not limited to these examples.

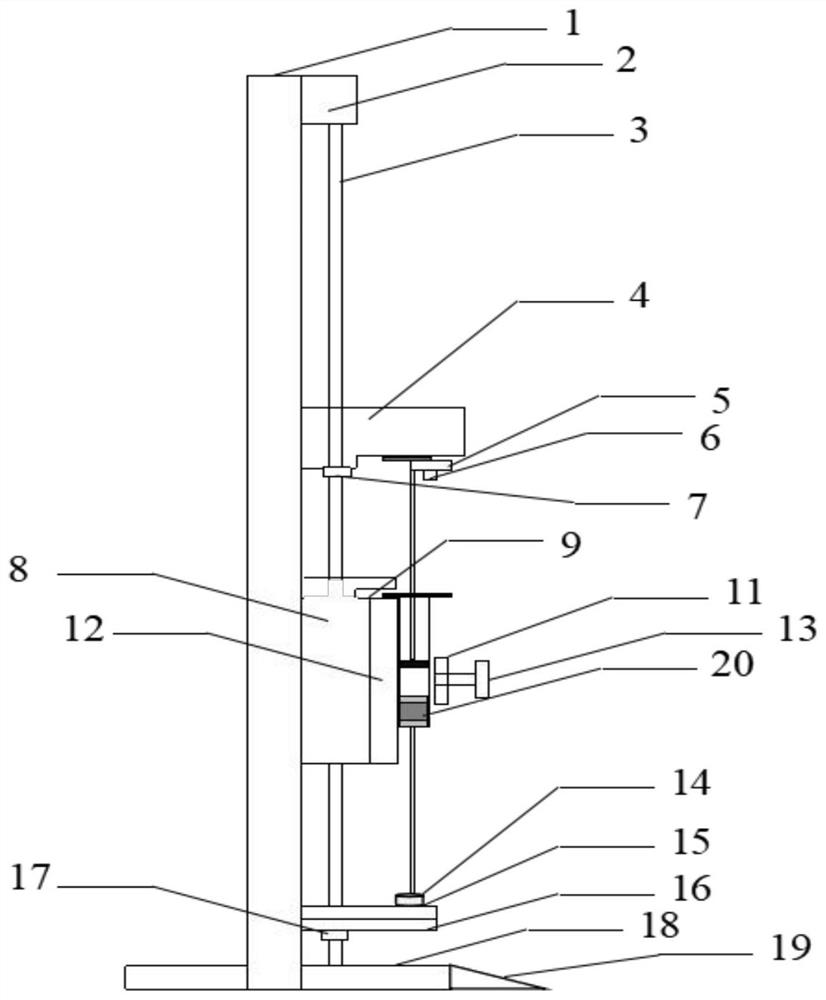

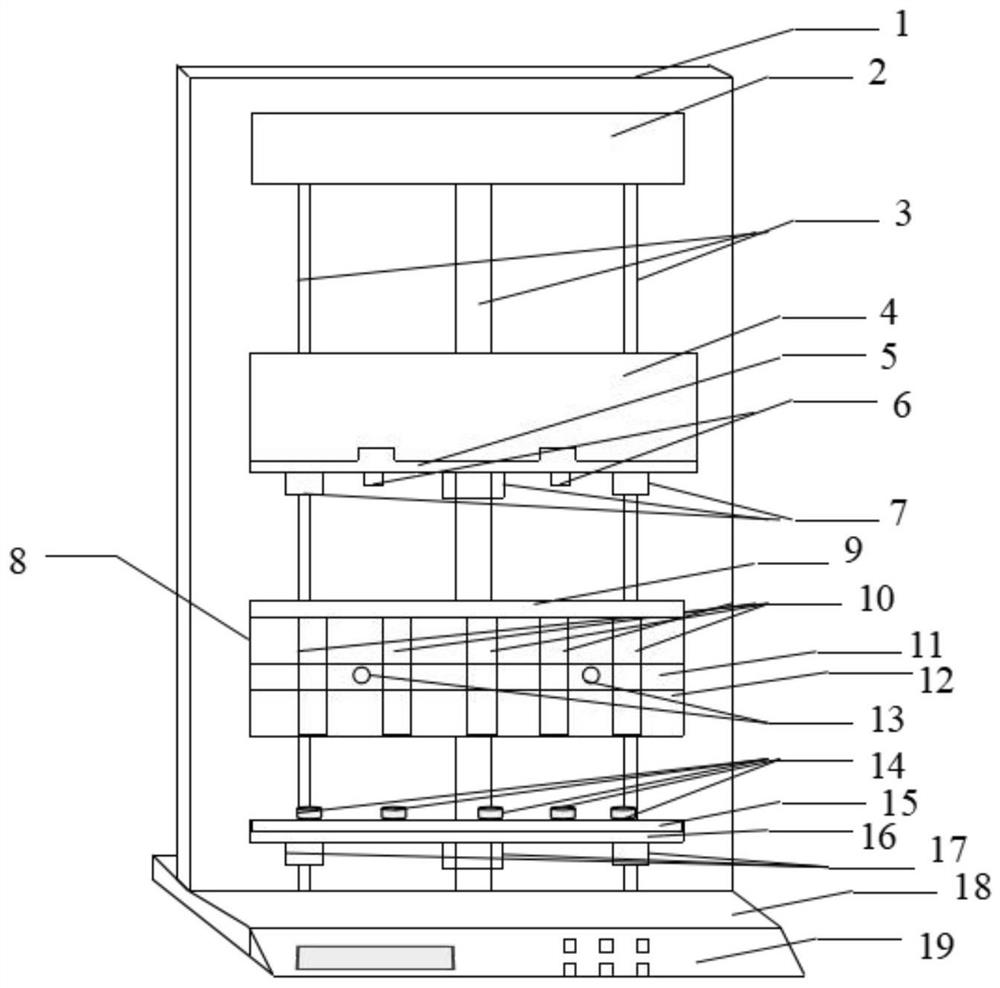

[0064] Multi-channel automatic purification device of the present invention, see Figure 1 ~ Figure 4 , comprising: a piston driving device and a plurality of purification columns 20;

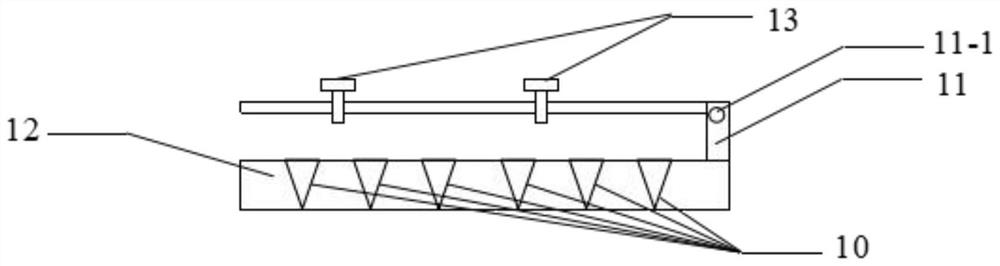

[0065] Wherein the structure of purification column 20 is shown in Figure 4 , including a piston assembly, a purification cylinder 20-4 and a purification layer;

[0066] The piston assembly includes a first end and a second end oppositely arranged, the first end is arranged in the purification cylinder, the second end extends out of the purification cylinder, and is connected with the piston driving device; specifically, the piston assembly includes a piston 20-5, a piston The handle 20-1 and the piston rod 20-2; one end of the piston rod 20-2 is connected to the piston 20-5 arranged in the purification cylinder 20-4, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com