Device for recovering ammonium and concentrated protein stock solution from ammonia-containing protein stock solution and method thereof

A technology for concentrating protein and proprotein, applied in fertilization equipment, peptide preparation methods, chemical instruments and methods, etc., can solve the problems of complicated purification process, high cost, affecting the reuse of protein stock solution, etc., and improve the efficiency of deamination , low cost, and high accuracy of the amount added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a method for recovering ammonium from an ammonia-containing protein stock solution and concentrating the protein stock solution.

[0056] A method for recovering ammonium from an ammonia-containing protein stock solution and concentrating the protein stock solution, comprising the steps of:

[0057] The ammonia-containing protein stock solution enters the removal mechanism 200 after adjusting the pH value to a predetermined range, and the removal mechanism 200 corrects the NH in the ammonia-containing protein stock solution. 4 + Convert to NH 3 to achieve removal.

[0058] The protein stock solution from the removal mechanism 200 enters the MVR forced circulation concentration mechanism 400 for concentration to obtain high-concentration protein stock solution and distilled water;

[0059] Containing NH from the removal mechanism 200 3 The gas enters the ammonia absorption mechanism 300 for adsorption, and the NH in the gas 3 Converted to (N...

Embodiment 2

[0061] This embodiment provides a method for recovering ammonium from an ammonia-containing protein stock solution and concentrating the protein stock solution.

[0062] A method for recovering ammonium from an ammonia-containing protein stock solution and concentrating the protein stock solution, comprising the steps of:

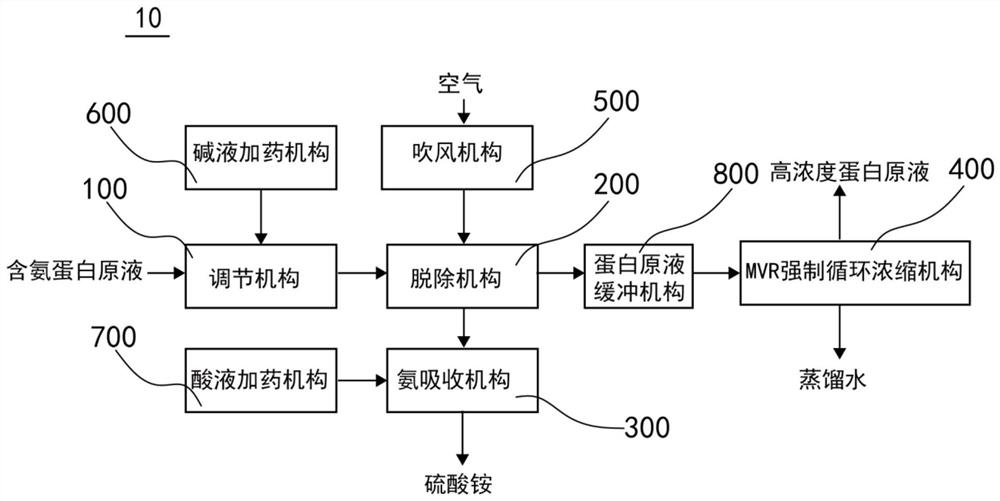

[0063] see figure 1 As shown, the ammonia-containing protein stock solution is input into the adjustment mechanism 100, the initial protein content of the ammonia-containing protein stock solution is 1.0-1.2%, the pH value is 10-12, and the ammonia nitrogen content is 1200-2500 mg / L.

[0064] The ammonia-containing protein stock solution enters the removal mechanism 200 after adjusting the pH value to 11.5-12 in the adjustment mechanism 100, and the removal mechanism 200 corrects the NH in the ammonia-containing protein stock solution 4 + Convert to NH 3 to achieve removal.

[0065] The protein stock solution from the removal mechanism 200 enters the MV...

Embodiment 3

[0068] This embodiment provides a method for recovering ammonium from an ammonia-containing protein stock solution and concentrating the protein stock solution.

[0069] A method for recovering ammonium from an ammonia-containing protein stock solution and concentrating the protein stock solution, comprising the steps of:

[0070] see figure 1 As shown, the ammonia-containing protein stock solution is input into the regulating mechanism 100, the initial protein content of the ammonia-containing protein stock solution is 1.0%, the pH value is 10, and the ammonia nitrogen content is 1200 mg / L.

[0071]The ammonia-containing protein stock solution enters the removal mechanism 200 after adjusting the pH value to 12 in the adjustment mechanism 100, and blows air to the removal mechanism 200 through the blower, and the ammonia-containing protein stock solution realizes NH in the removal mechanism 200. 4 + Convert to NH 3 To achieve removal, and to obtain protein stock solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com