An adjustable storage box for knitted fabrics

A knitted fabric, adjustable technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of increased labor, inability to classify fabrics, and the fabric storage device does not have the function of rolling fabrics, and achieves convenient storage. , The effect of convenient storage work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

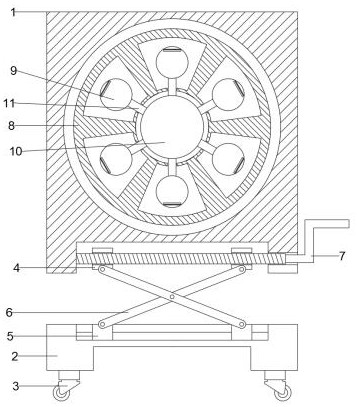

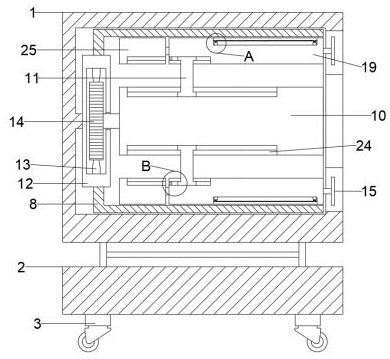

[0029] see Figure 1-6 , in an embodiment of the present invention, an adjustable storage box for knitted fabrics includes a box body 1 and a base 2, a lifting assembly is arranged between the box body 1 and the base 2 for adjusting the height of the box body 1, It is convenient for staff of different heights to take and place the cloth. The lifting assembly includes a first slider 4 and a second slider 5. A threaded rod is installed in the box 1. The first slider 4 is symmetrically threaded on the On the threaded rod, the second slider 5 is symmetrically slid on the base 2, and a connecting rod 6 is symmetrically hinged between the first slider 4 and the second slider 5, and the threaded rod rotates to drive the first slider The blocks 4 move toward each other along the threaded rods, thereby driving the connecting rods 6 to move, thereby adjusting the distance between the base 2 and the box body 1 and indirectly adjusting the height of the box body 1 .

[0030] Further, bec...

Embodiment 2

[0033] In this embodiment, a further improvement is made on the basis of embodiment 1, and the content of the improvement is that universal wheels 3 are symmetrically installed and fixed on the lower surface of the base 2, so as to facilitate the movement of the whole device.

[0034] One end of the threaded rod is connected and fixed with a rocker 7, which is convenient for the staff to rotate the threaded rod to adjust the height of the box body 1.

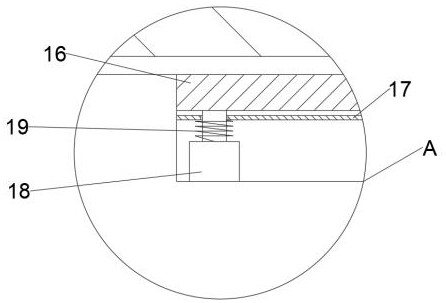

[0035] Further, in order to prevent the slide bar 11 from entering the second chute 22 in advance before being interfered by the third chute 24, a baffle 20 is symmetrically hinged in the first chute 21, and the baffle 20 is connected with the first chute. 21 hinges are provided with a second torsion spring.

[0036] Further, in order to facilitate the staff to rotate the cloth rolling roller 9 to carry out the cloth winding process, one end of the cloth rolling roller 9 is pivoted and fixed with a rotating rod 15 .

[0037] Fu...

Embodiment 1

[0038] In conjunction with embodiment 1, embodiment 2, working principle of the present invention is:

[0039]When using the present invention, by turning the handle 7, the threaded rod is driven to rotate, thereby driving the first slider 4 to move toward each other along the threaded rod, thereby driving the connecting rod 6 to move, thereby adjusting the distance between the base 2 and the box body 1 , indirectly adjust the height of the box body 1, by rotating the middle column 10, thereby driving the ratchet wheel 14 to rotate, and under the action of the hinge teeth 13, the middle column 10 is rotated in one direction, thereby driving the rotating bin 8 to rotate, so as to realize the rolling in different positions The position conversion of the cloth roller 9 not only facilitates the storage of different types of cloth rollers, but also facilitates the storage of the cloth by the staff. Under the action of the third chute 24, the cloth roll 9 is pulled outward. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com