Telescopic adjustable placing rack for tempered glass production

A technology of toughened glass and telescopic adjustment, which is applied to multi-axis trolleys, trolley accessories, trolleys, etc., can solve the problems of inability to stack, weak applicability, waste of resources, etc., to save storage space, easy to carry and store, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

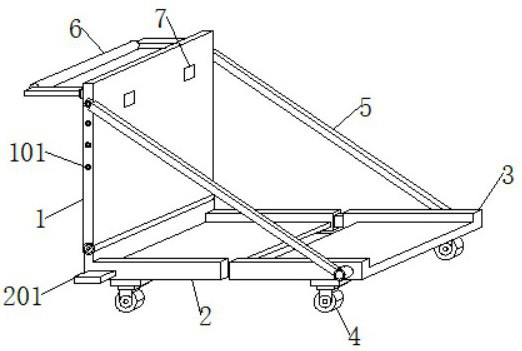

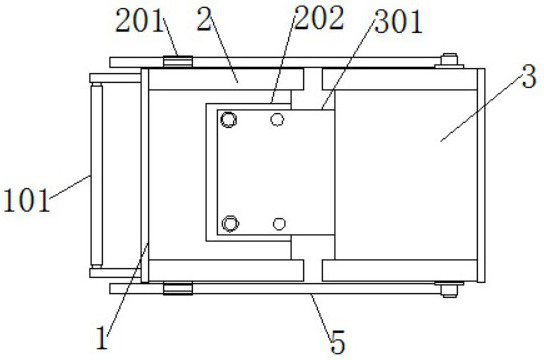

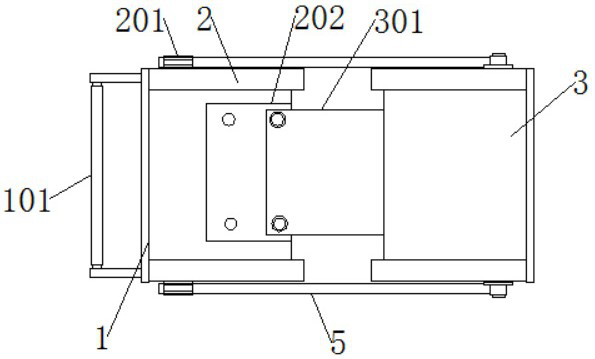

[0017] Example: see Figure 1-3 Among them, a retractable and adjustable placing frame for tempered glass production provided in this embodiment includes a baffle plate 1, a main base plate 2 and an armrest 6, the bottom side of the baffle plate 1 is connected to the main base plate 2 through a rotating shaft, and the baffle plate 1 One side of the top is fixed with a handrail 6 by bolts, a plurality of fixing holes 101 are arranged on both sides of the baffle plate 1, brackets 201 are arranged on both sides of the main bottom plate 2, and a chute 202 is arranged on an opening inside the main bottom plate 2, and the chute 202 is slidingly connected with a connecting plate 301, one side of the connecting plate 301 is fixed with a sub-base plate 3 by bolts, the sub-base plate 3 and the bottom of the main base plate 2 are respectively provided with two universal wheels 4, and the two sides of the sub-base plate 3 are connected by rotating shafts There are two support rods 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com