Device and method for monitoring (detecting) pollution degree of hydraulic oil particles sampled from drain valve

A hydraulic oil and pollution degree technology, applied in sampling devices, measuring devices, fluid pressure actuating devices, etc., can solve the problems of inaccurate and true results, uneven distribution of particulate pollutants, etc. Avoid misjudgment and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

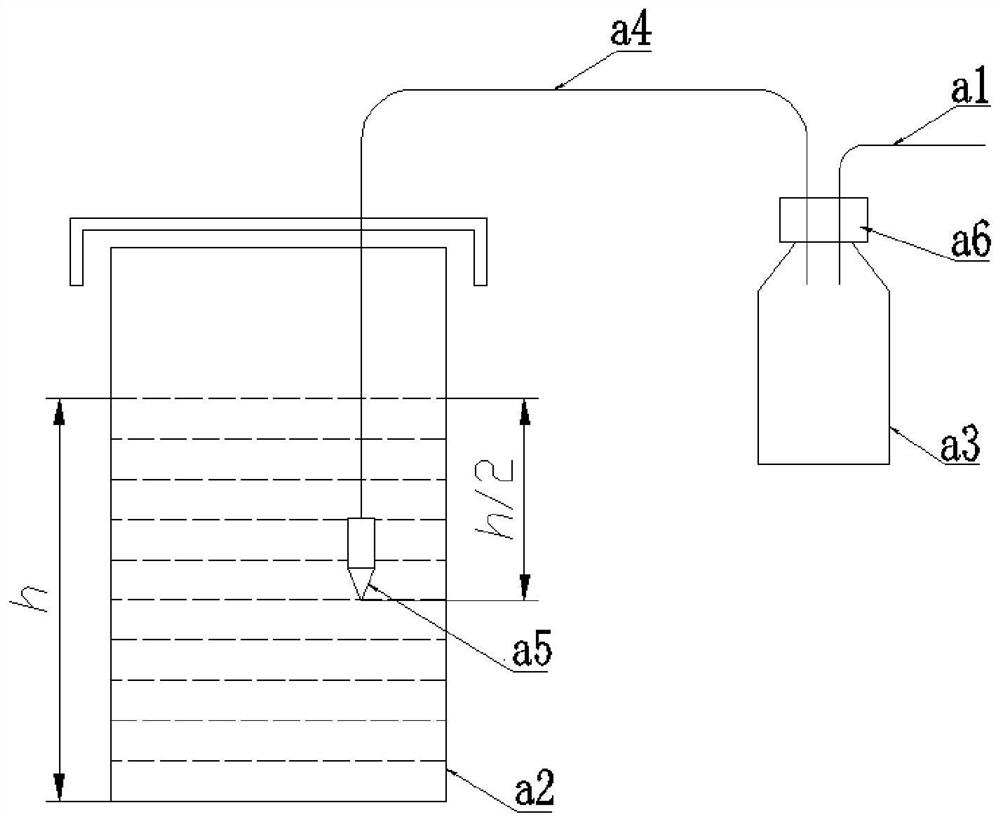

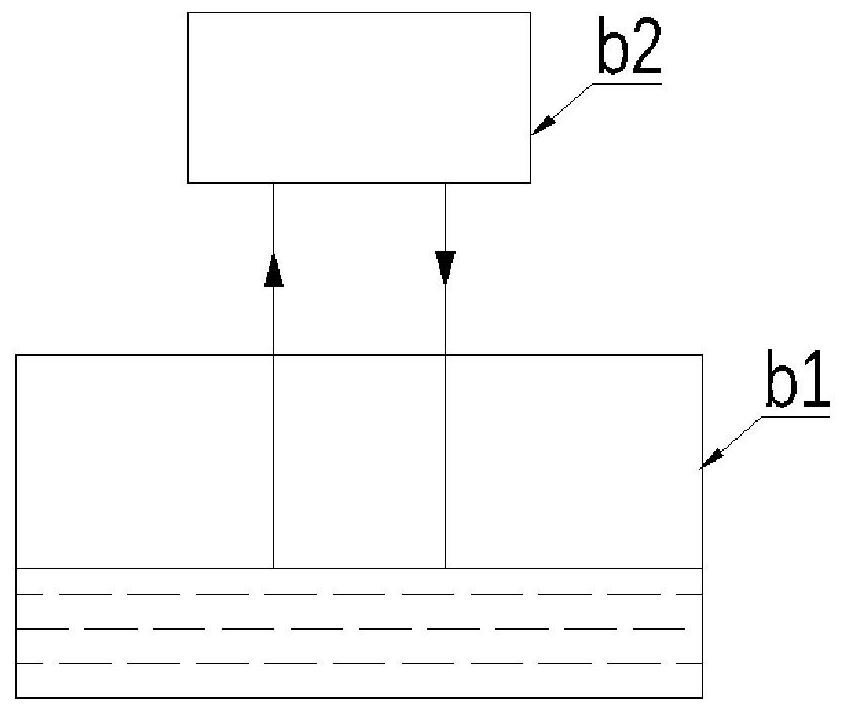

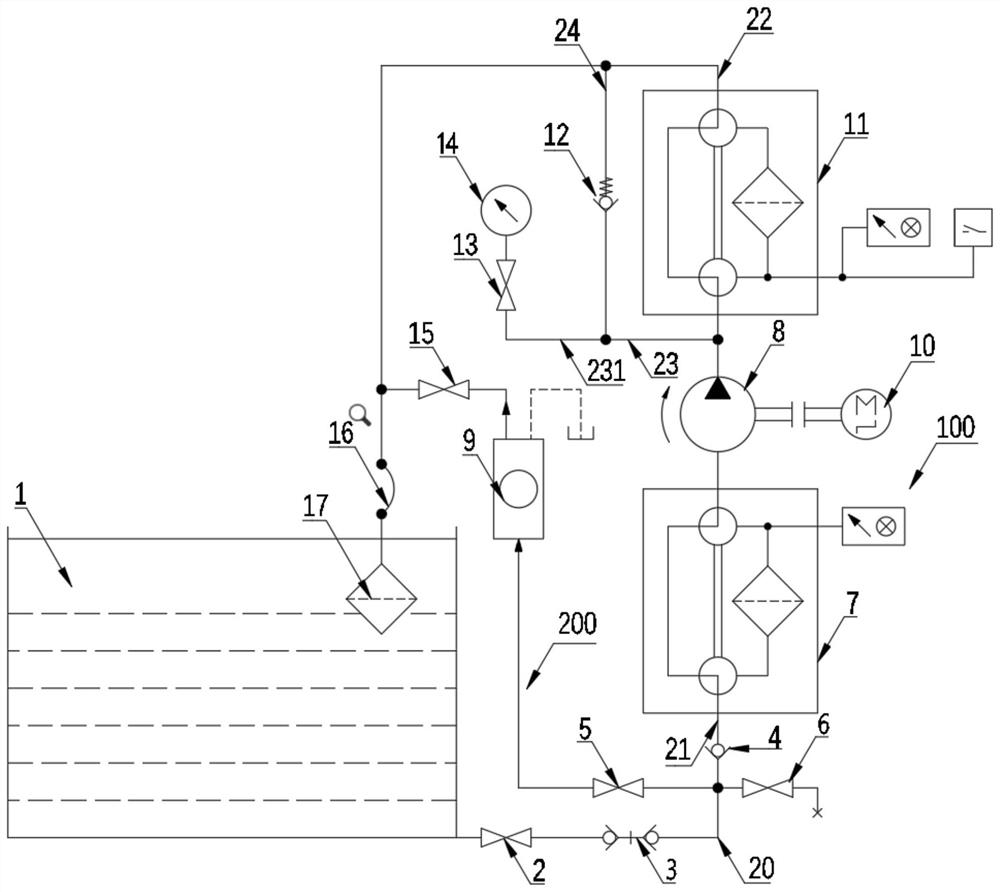

[0061] Embodiments of the present disclosure provide a hydraulic oil particle pollution degree monitoring (detection) device in order to solve or at least partly solve the above-mentioned problems. will now refer to figure 1 Some example embodiments will be described. Note that in the following description, "hydraulic fluid" may be used as a sample for monitoring (testing). But the scope of the present disclosure is not limited thereto, and any monitoring (detection) device that can be used as described herein is included in the scope of the present disclosure.

[0062] Embodiments of the present disclosure provide a monitoring (detection) device for particle pollution degree of hydraulic oil sampled from a drain valve, so as to solve or at least partly solve the above-mentioned problems. will now refer to figure 1 Some example embodiments will be described. Note that in the following description, "hydraulic fluid" may be used as a sample for monitoring (testing). But the...

Embodiment 2

[0074] like Figure 4 As shown, the embodiment of the present disclosure provides a method for monitoring (detecting) the contamination degree of hydraulic fluid particles sampled from the drain valve. Those skilled in the art should understand that this embodiment is described with the monitoring (detection) device provided in Embodiment 1, but it is not limited thereto. The method includes:

[0075] S1: Sampling: Obtain the hydraulic oil to be monitored (tested) in the fuel tank from the drain valve on the fuel tank. Specifically, the embodiment

[0076] After the monitoring (testing) testing device in 1 is assembled, take samples according to the following steps. For specific steps, see S11-S14.

[0077] S11: Clean the interface of the drain valve 2 and the quick coupling 3 with double check valves.

[0078] Specifically, clean the interface of the drain valve 2 and the interface of the double one-way valve quick-change joint 3 (one end) with a cleaning rag or cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com