Self-priming centrifugal pumps for gas-liquid mixtures

A self-priming centrifugal pump and gas-liquid mixing technology, which is applied in the field of centrifugal pumps, can solve problems such as the centrifugal pump head flow range is not wide enough, the centrifugal pump has no self-priming ability, and cannot meet the needs of use, so as to facilitate later maintenance and management, The effect of reducing sundries entering the pump body and facilitating disassembly, cleaning and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

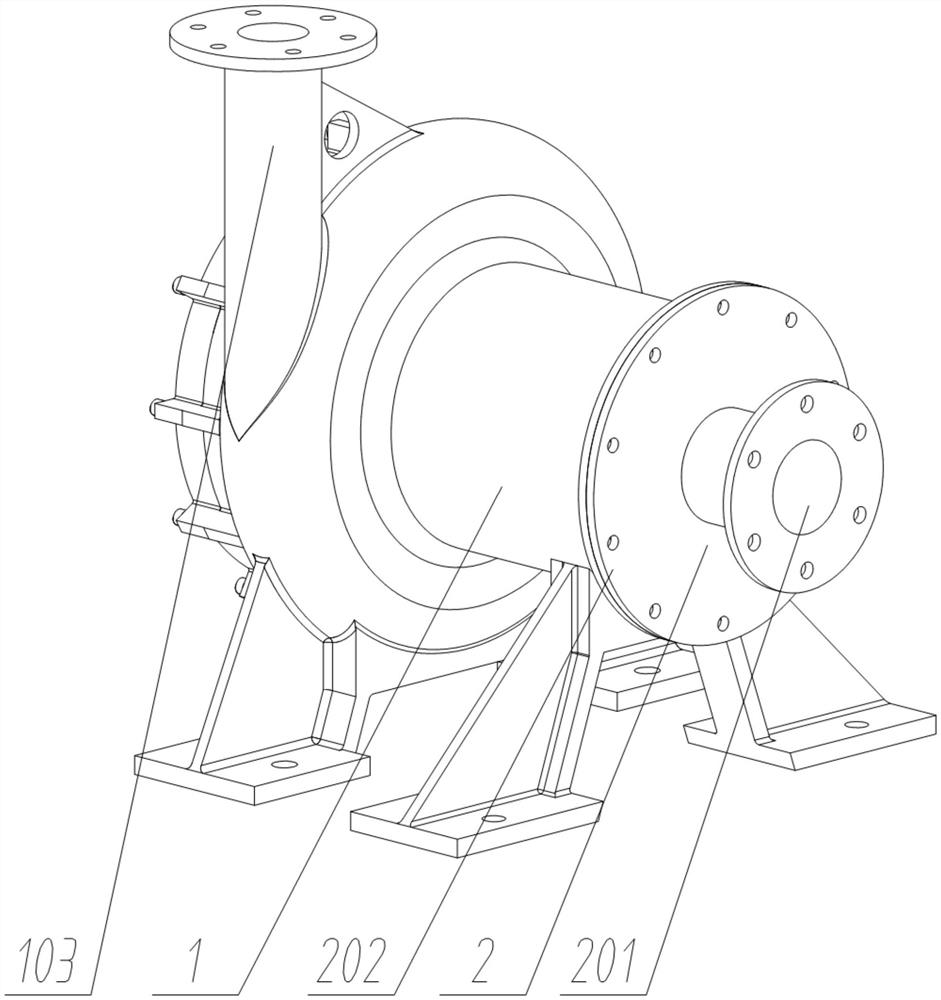

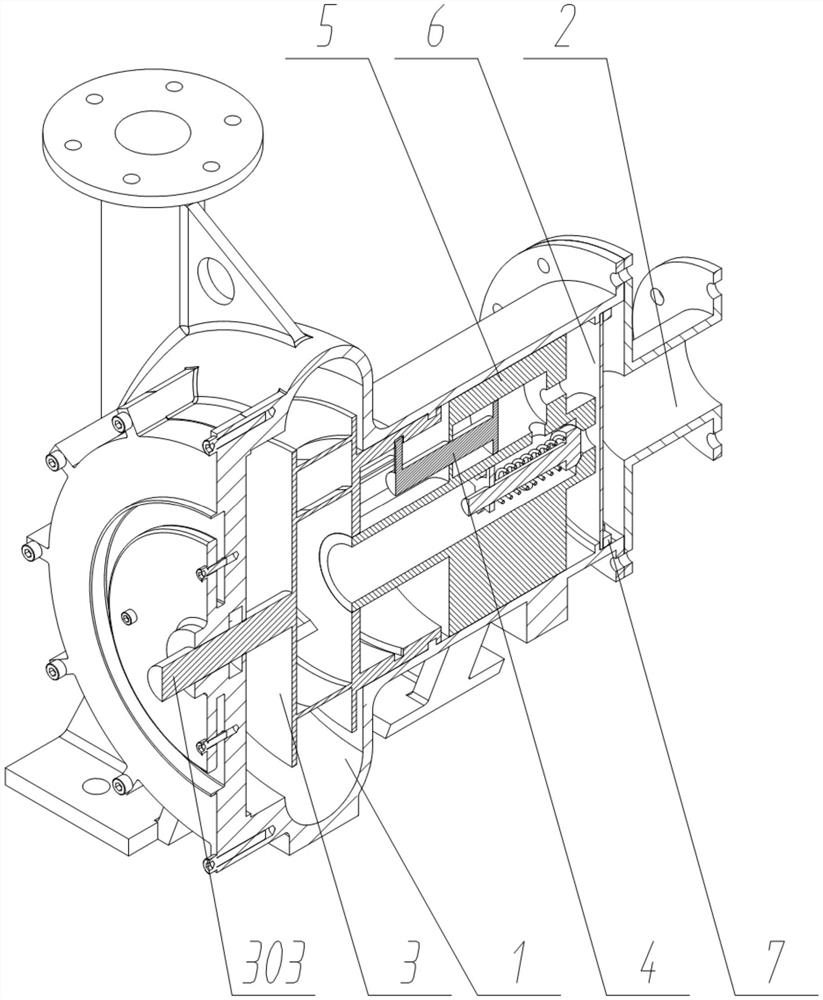

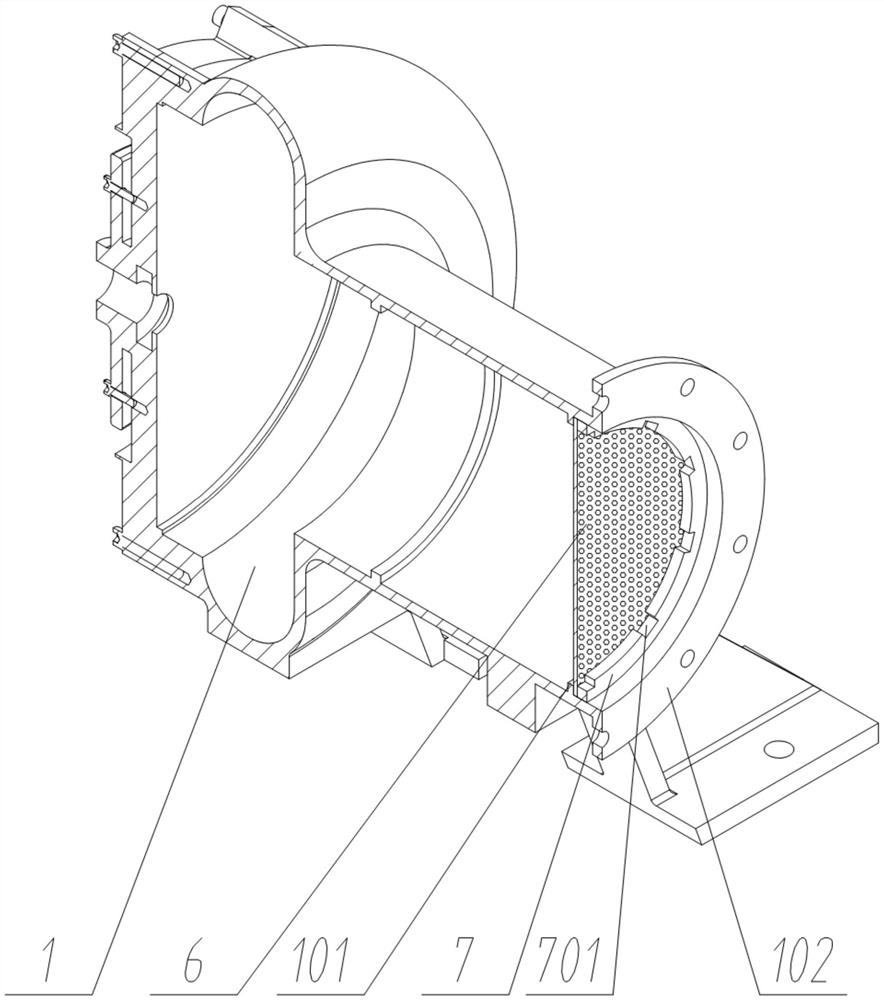

[0032] see Figure 1 to Figure 9 , the present invention provides a self-priming centrifugal pump capable of handling gas-liquid mixed media, including an outer casing 1; a group of water inlet casings 2 are fastened to the right side of the outer casing 1, and the outer casing 1 also includes an outlet Water outlet 103 , a group of water outlets 103 is provided on the top of the outer casing 1 . The water inlet housing 2 also includes a water inlet 201 , and a group of water inlets 201 is provided on the right side of the water inlet housing 2 . In use, water enters through the water inlet 201 and exits through the water outlet 103 . The outer casing 1 also includes an outer casing water inlet connection flange 102, a group of outer casing water inlet connection flanges 102 are arranged on the right end surface of the outer casing 1, and the water inlet casing 2 also includes a water inlet casing connection flange 202, The left end face of the water inlet shell 2 is fixedly...

Embodiment 2

[0034] In a preferred embodiment, the impeller body 3 also includes blades 304, six sets of blades 304 are arranged inside the impeller body 3, the blades 304 are involute centrifugal blades, and the rotation of the blades 304 produces centrifugal action to dissipate the water in use. Push outward.

[0035]In a preferred embodiment, the impeller body 3 also includes an impeller guide groove 302, and a group of annular impeller guide grooves 302 are arranged on the right side of the impeller body 3, and the impeller body 3 is rotationally connected with the outer casing 1 through the impeller guide groove 302 , the outer housing 1 is guided through the impeller guide groove 302 in use.

Embodiment 3

[0037] In a preferred embodiment, the piston rod 4 also includes a piston guide groove 402, two sets of piston guide grooves 402 are arranged on the outside of the piston rod 4, and the piston rod 4 is slidingly connected with the piston cylinder body 5 through the piston guide groove 402. The piston rod 4 is guided through the piston guide groove 402 .

[0038] In a preferred embodiment, the piston cylinder 5 also includes a piston water inlet 502 and a piston water outlet 503, a group of piston water inlets 502 are arranged on the right side of the piston chamber 501, and a group of piston water outlets 503 are arranged inside the piston chamber 501 , the piston water outlet 503 opens toward the cavity in the middle of the piston cylinder 5, and a group of one-way valves are respectively arranged inside the piston water inlet 502 and the piston water outlet 503, and the one-way valve in the piston water inlet 502 opens to the piston cavity 501, and the piston The one-way val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com