A kind of preparation method of emulsifier based on polyhydroxy linear polymer

A technology of polyhydroxy straight chain and polymer, which is applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc. It can solve the problems of reduced stability, increased emulsion viscosity and particle size, etc., to achieve optimal performance, The effect of cheap price and good wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

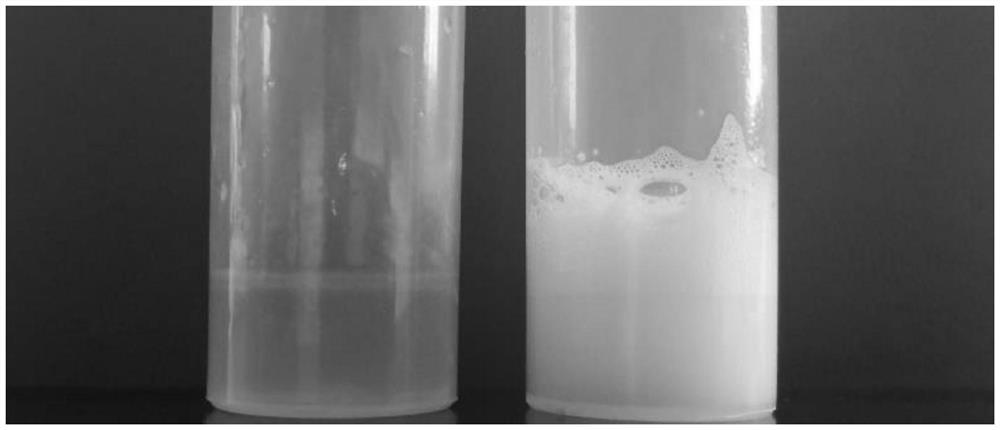

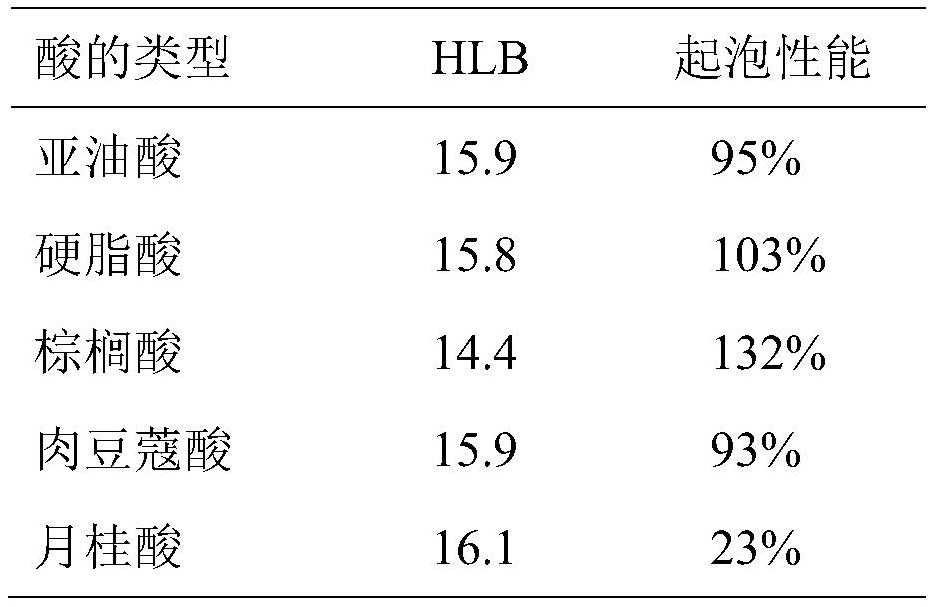

Image

Examples

Embodiment 1

[0024] 1) Synthesis of hydrophilic group-polyhydric linear polymer: Weigh glycidol (19.3g, 0.258mol) and dissolve it in 150mL vinyl ether, equilibrate in ice bath, add slowly while stirring p-toluenesulfonic acid (992mg, 5.214mmol), after ice bath for 10min, return to room temperature and react for 3h, then use saturated NaHCO 3 The solution was washed with water, dried and filtered over anhydrous sodium sulfate, and then spin-dried, and the product (15.26 g, 0.106 mmol) was obtained by a vacuum distillation device with a yield of 41%.

[0025] Take by weighing last step gained product (8g, 55.5mmol) and join in the reaction flask, use N 2 The air in the reaction flask was replaced, then potassium tert-butoxide tetrahydrofuran solution (1.03 mL, 1.03 mmol) was slowly added, and the reaction was stirred at 60° C. for 24 h. The reaction was quenched with methanol, diluted with dichloromethane and washed with brine and water, the organic phase was separated and spin-dried. Add ...

Embodiment 2

[0029] The consumption of glycidyl alcohol among the embodiment 1 is increased to four times of original, other is unchanged, and the productive rate of synthesizing high molecular emulsifier is 45%.

Embodiment 3

[0031] The amount of linoleic acid in Example 1 was increased to four times the original amount, and the others remained unchanged, and the yield of the synthetic polymer emulsifier was 33%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com