Flat copper wire feeding device and wire feeding method

A wire feeding device and flat copper wire technology, which is applied in the field of new energy flat copper wire motor manufacturing equipment, can solve problems such as deformation, mutual entanglement, and easy bending, and achieve shortened length, reduced floor space, and compact layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

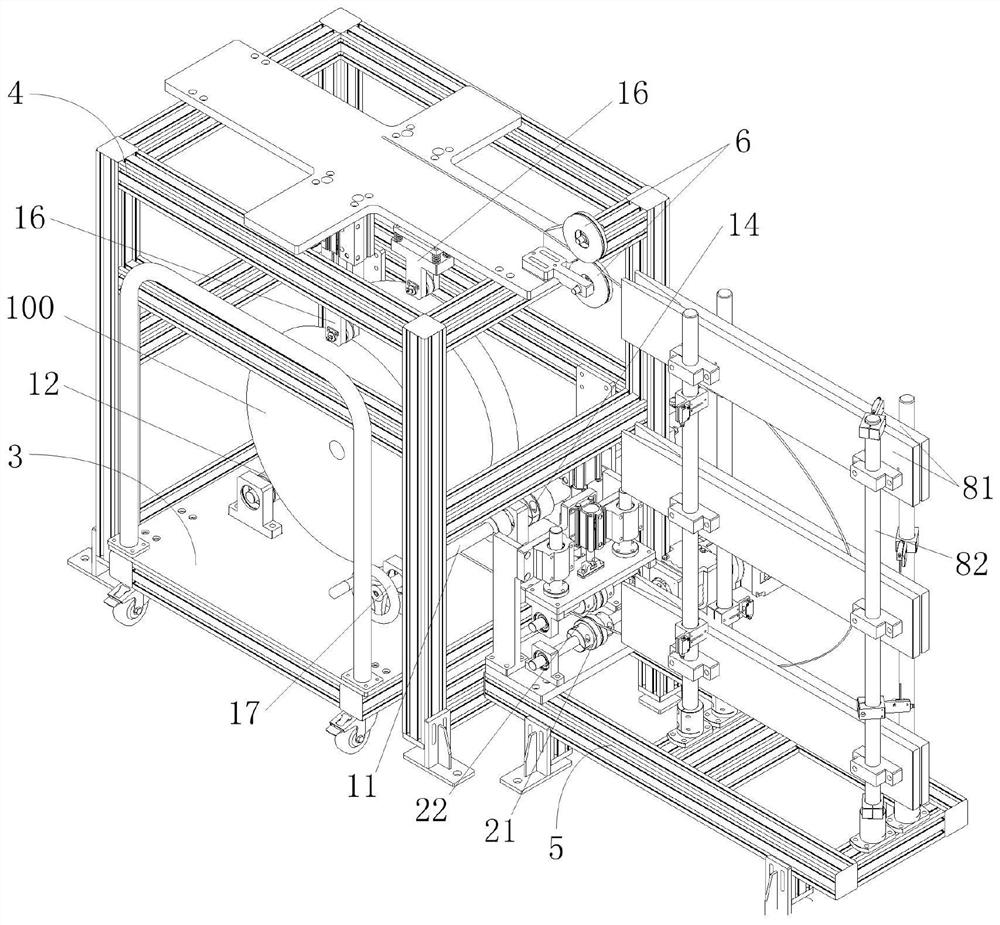

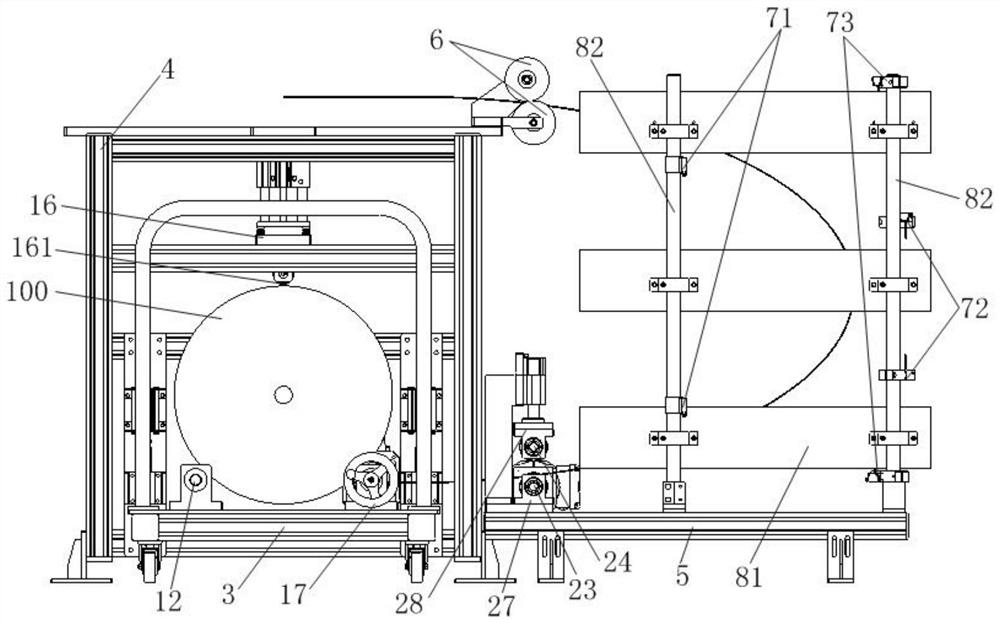

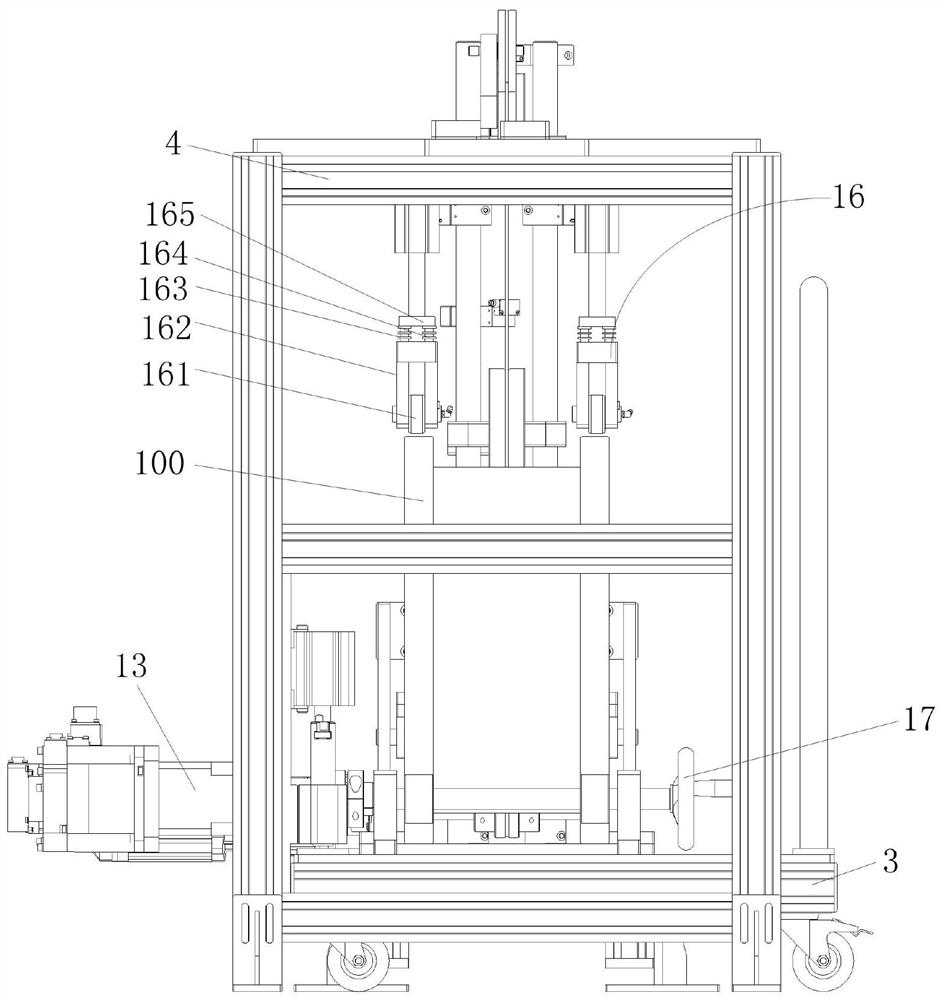

[0033] The flat copper wire feeding device of the present invention comprises a feeding frame 4, a first drive mechanism for driving the rotation of the wire roller 100 loaded with rolled flat copper wire, a second drive mechanism for conveying the flat copper wire, The wire roller transport trolley 3 used to transport the wire roller 100 to the flat copper wire feeding station, the wire feeding installation frame 5 for installing the second driving mechanism, and the wire feeding installation frame 5 for controlling the first driving mechanism and A controller for the operation of the second drive mechanism. The feeding frame 4 has a receiving opening for receiving the wire roller transport t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com