An automatic production line for casting zinc alloy

An automatic production line and zinc alloy technology, applied in foundry workshops, casting equipment, manufacturing tools, etc., can solve the problems of inability to respond quickly to the market, high labor intensity of personnel, and low degree of automation, so as to reduce labor intensity of workers and achieve good cooling effect , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

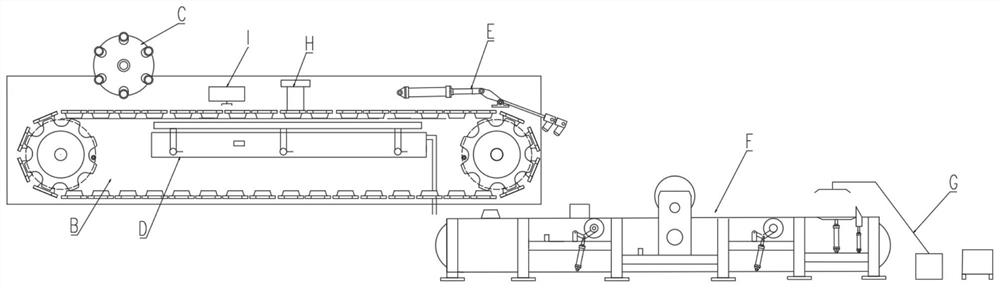

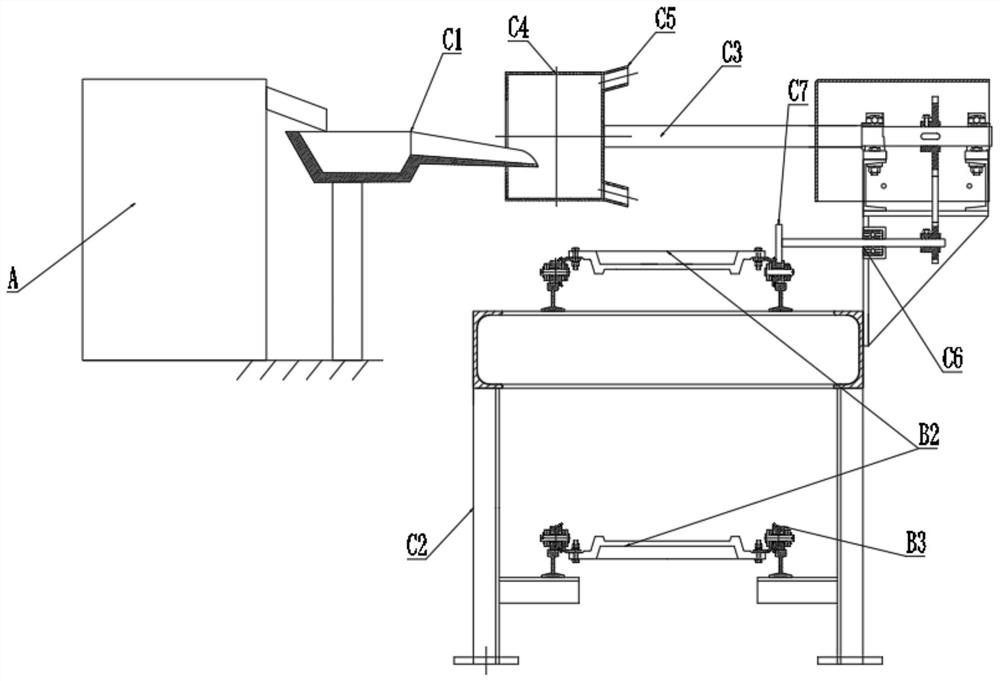

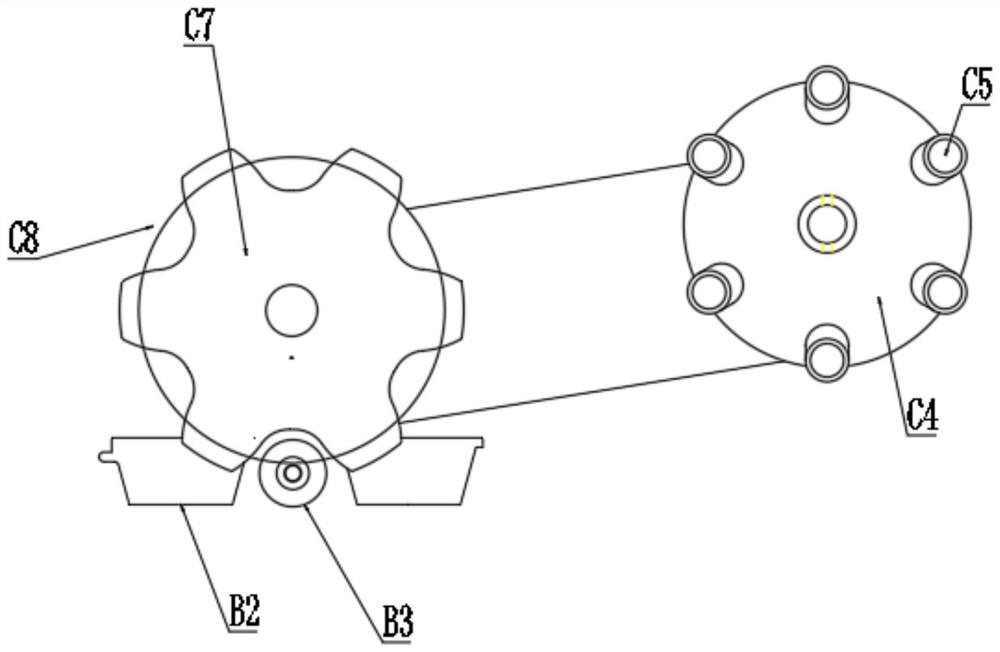

[0035] Such as figure 1 As shown, an automatic production line for casting zinc alloy, linear ingot casting machine B, automatic casting device C, cooling system D, automatic demoulding device E, alignment machine F and automatic stacking device G; the linear ingot casting machine B The conventional linear ingot casting machine B is mainly composed of chain link conveyor belt B1 and ingot mold B2 installed on the surface of chain link conveyor belt B1. Both ends of ingot mold B2 are connected with chain link conveyor belt B1 through pin shaft B3. The front end of linear ingot casting machine B is docked with the exit of holding furnace A, and the rear end is connected with alignment machine F. An automatic casting device for casting zinc alloy is installed at the joint between linear ingot casting machine B and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com