Chemical dissolving tank for sewage treatment and using method thereof

A technology of sewage treatment and dissolution tank, which is applied in the direction of dissolution, dissolution, and mixing methods, and can solve the problems of poor disinfection effect, difficult dissolution, and increased workload of stirring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

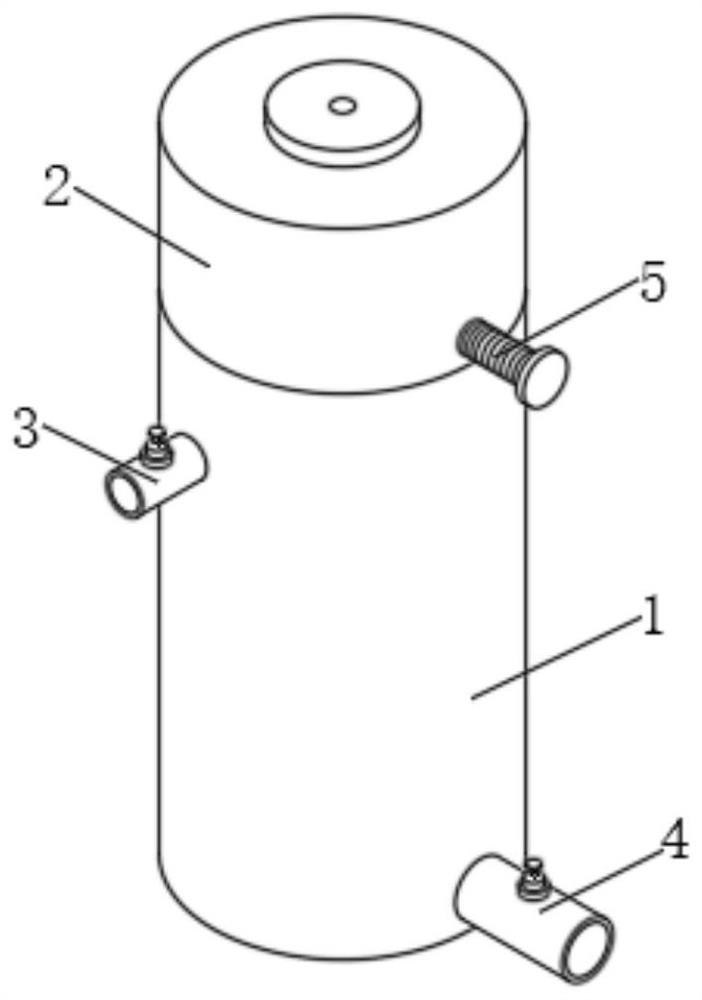

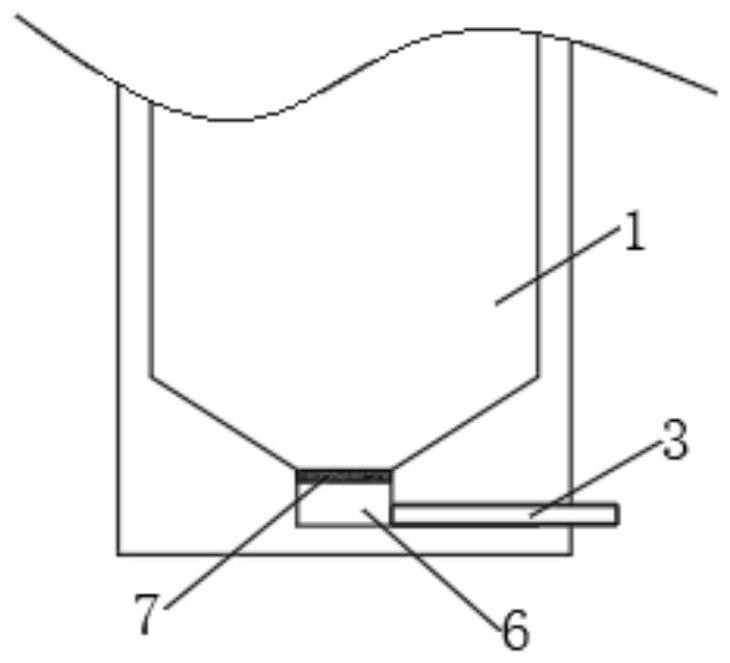

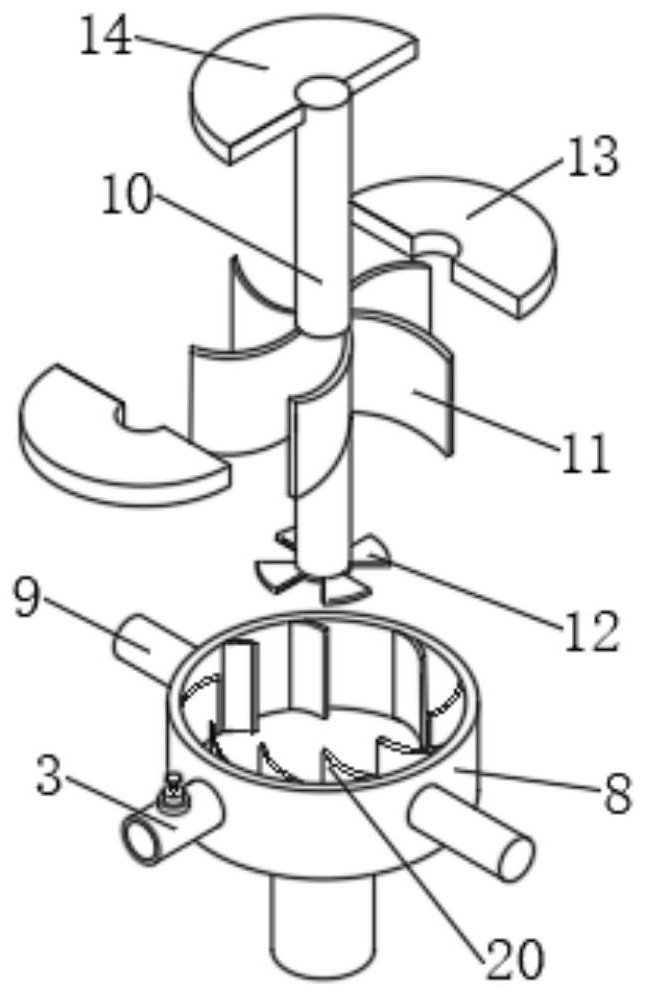

[0028] Embodiments of the present invention provide a chemical dissolving tank for sewage treatment and its use method, such as Figure 1-6 As shown, it includes a mixing box 1, the upper surface of the mixing box 1 is fixedly connected with a medicine warehouse 2, the top outer surface of the mixing box 1 is fixedly connected with a water inlet pipe 3, and the bottom outer surface of the mixing box 1 is fixedly connected with an outlet pipe 4, The outer surface of the medicament chamber 2 is movably clamped with the adjustment assembly 5, the water inlet pipe 3 extends to the interior of the mixing box 1 and is fixedly connected to the organic casing 8, the outer surface of the casing 8 is fixedly connected to the support rod 9, and the internal bearing of the casing 8 A rotating shaft 10 is connected, the outer surface of the rotating shaft 10 is fixedly sleeved with an impeller 11 inside the casing 8, the outer surface of the bottom end of the rotating shaft 10 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com