Dish-washing machine having rotary spray arm

A technology of rotary spraying and dishwasher, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, household utensils, etc., which can solve the problems of poor cleaning ability, improve efficiency, reduce Energy consumption, effect of improving cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

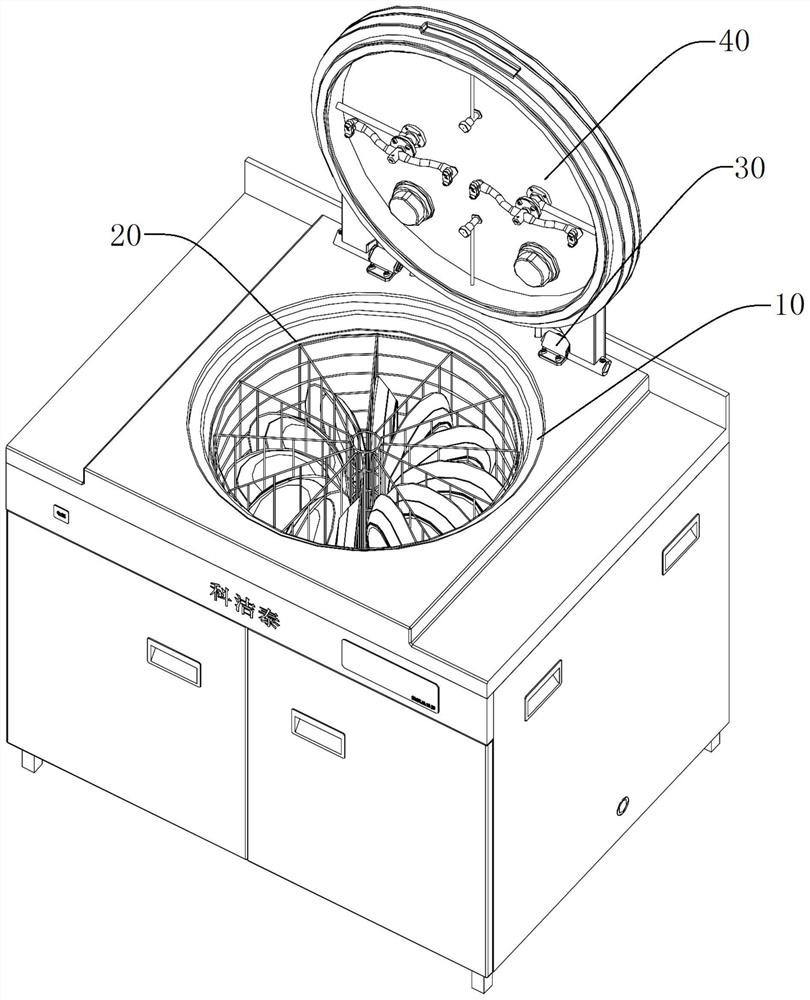

[0040] Such as figure 1 As shown, this embodiment includes a machine body 10 , the machine body 10 is provided with a rotary tub assembly 20 and a fixed seat 30 , and a dishwasher cover 40 is rotatably disposed on the fixed seat 30 , and the dishwasher cover 40 is set corresponding to the rotary tub assembly 20 .

[0041] Such as Figure 4a , Figure 5 and Figure 6a As shown, the dishwasher cover 40 includes a cover plate 41, a fixed plate 42, an upper cover 43, and a lower cover 44 arranged in sequence. A spacer 47 is arranged between the cover plate 41 and the fixed plate 42, and is glued to each other. Fixed, the first cavity 45 is formed by separating the spacer ring 47, the upper cover 43 and the lower cover 44 are assembled and fixed by means of spot welding or gluing, and a second cavity 46 is formed between the two, and the fixing plate 42 is fixed On the upper cover body 43 and the lower cover body 44 . Both the cover plate 41 and the fixing plate 42 can be made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com