Sugar diced apple processing equipment and technological process thereof

A processing equipment and apple diced technology, which is applied in the confectionary industry, confectionery, food processing, etc., can solve the problems of quality decline, insufficient apple soaking, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

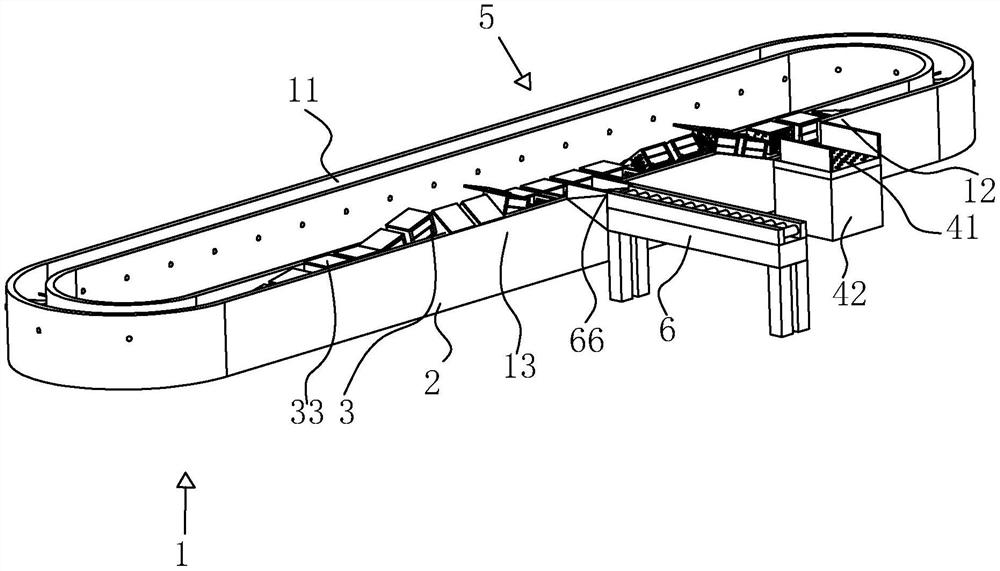

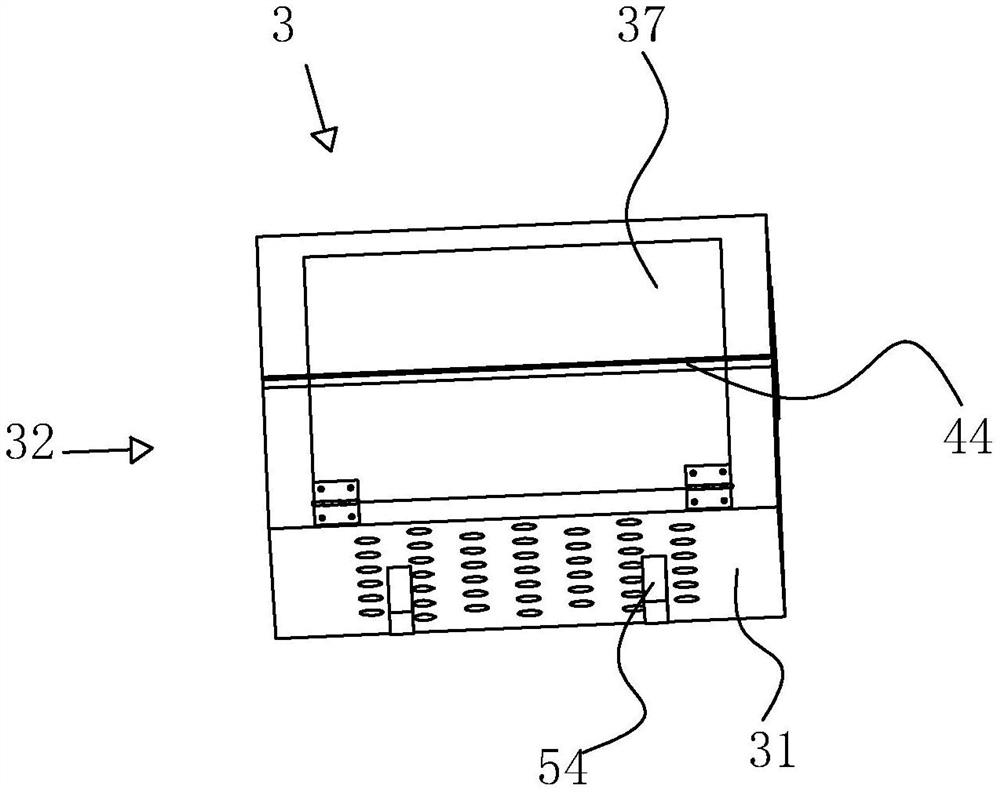

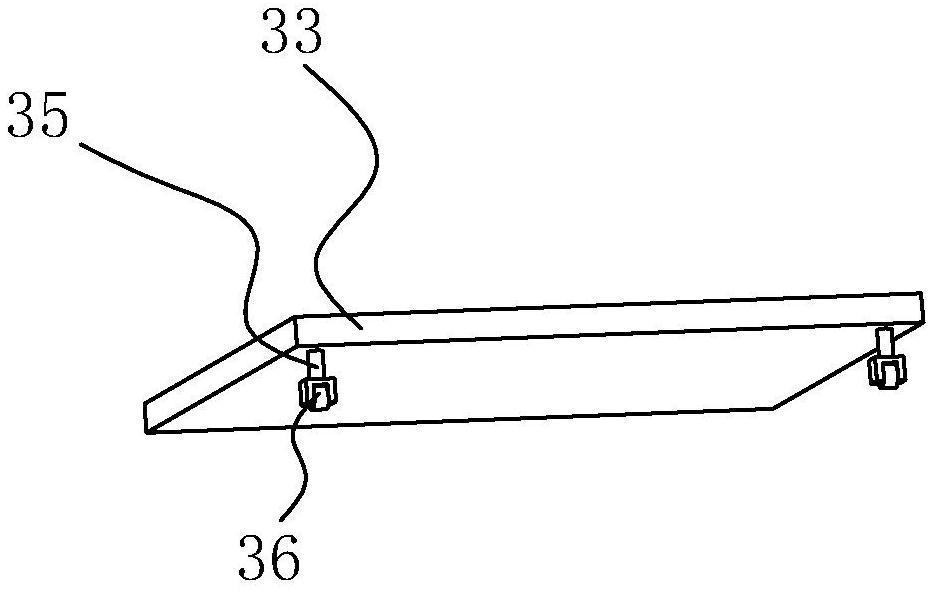

[0054] refer to figure 1 , a diced apple sugar processing equipment, comprising a soaking tank 1 and a washing machine 6, soaking liquid is filled in the soaking tank 1, and the apples cleaned by the washing machine 6 are soaked. The soaking tank 1 includes a feeding section 13, a discharging section 12 and a soaking section 11. The lower end of the soaking tank 1 is provided with a base 2, and the soaking tank 1 is provided with several closely arranged soaking boxes 3 and driving mechanisms 5. The soaking box 3 is used for soaking and holding apples. The apples are fed into the soaking box 3 in the feeding section 13, soaked in the soaking liquid in the soaking section 11, and finished in the soaking box 3 in the discharging section 12. output. The driving mechanism 5 can drive the soaking tank 3 to move circularly in the soaking tank 1 from the feeding section 13 to the soaking section 11 and then to the discharging section 12, thereby realizing continuous production.

[...

Embodiment 2

[0065]refer to Figure 9 with Figure 10 , the difference between this embodiment and Embodiment 1 is that loam cake 33 comprises loam cake one 331 and loam cake two 332, and the lower end of loam cake one 331 and loam cake two 332 are all provided with sliding wheel bar 7, soaking tank 1 The upper end is provided with a sliding wheel groove 78, and the lower end of the sliding wheel bar 7 is provided with a sliding wheel 79 matched with the sliding wheel groove 78. The upper cover one 331 and the upper cover two 332 can realize sliding through the cooperation of the sliding wheel 79 and the sliding wheel groove 78. Open and close, and the sliding direction of the upper cover 1 331 and the upper cover 2 332 is perpendicular to the moving direction of the soaking tank 3 .

[0066] Upper cover 1 331 and upper cover 2 332 collide with a vertical gap 77, and the end of feeding section 13 near the discharge section 12 is provided with bracket 76, and bracket 76 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com