Rice dumpling preparation method

A production method and technology of rice dumplings, which are applied in the fields of food science, food preservation, application, etc., can solve the problems of low production efficiency, waste of energy, increase production cost, etc., and achieve the effects of shortening cooking time, increasing cold water immersion, and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

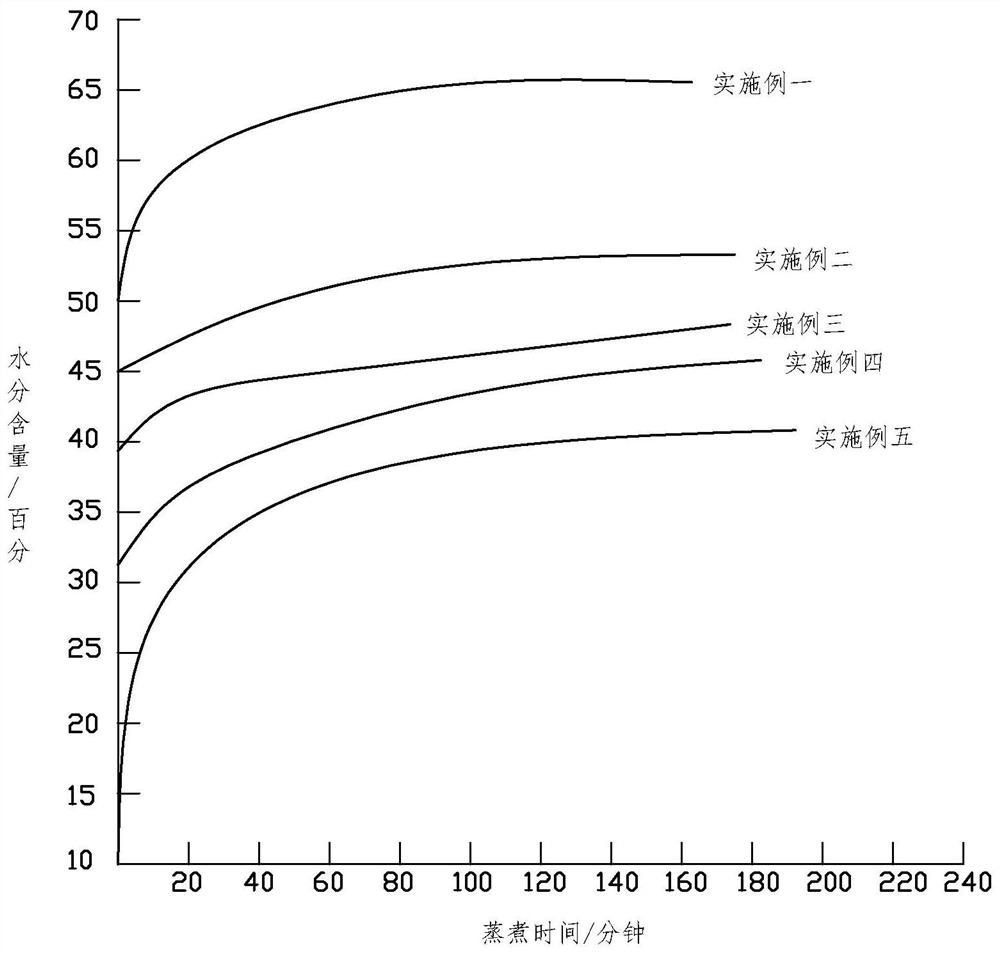

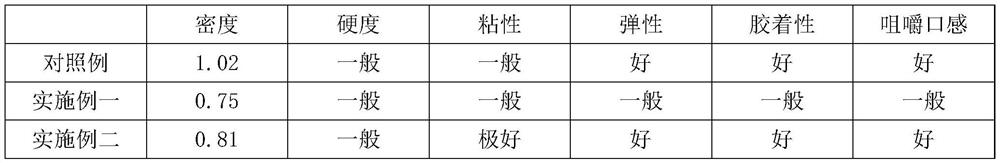

Embodiment 1

[0042] 1) Pretreatment of zong leaves: After washing the zong leaves, put them in boiling water at 100 degrees Celsius for 15 minutes, then take out and soak them in cold water until they are soft and not broken;

[0043] 2) Soaking glutinous rice: Weigh a certain quality of glutinous rice, wash it twice with clean water, add an appropriate amount of water according to the mass ratio of 1:2 to soak, soak for a certain period of time, drain the water with a screen;

[0044] 3) Packaging: Take two zongzi leaves, fold them into a cone and place them in a mold, add 100g of soaked glutinous rice, and tie them with rice noodles; the packaging density of zongzi is 0.75 g / ml; the packaging density of zongzi refers to The bulk density of the zongzi after packaging, the drainage method to measure its volume and calculate its density. ρ=m / V, in the formula: ρ: packing density of zongzi; m: mass of zongzi; V: volume of zongzi measured by drainage method.

[0045] 4) One-time cooking: Put the ri...

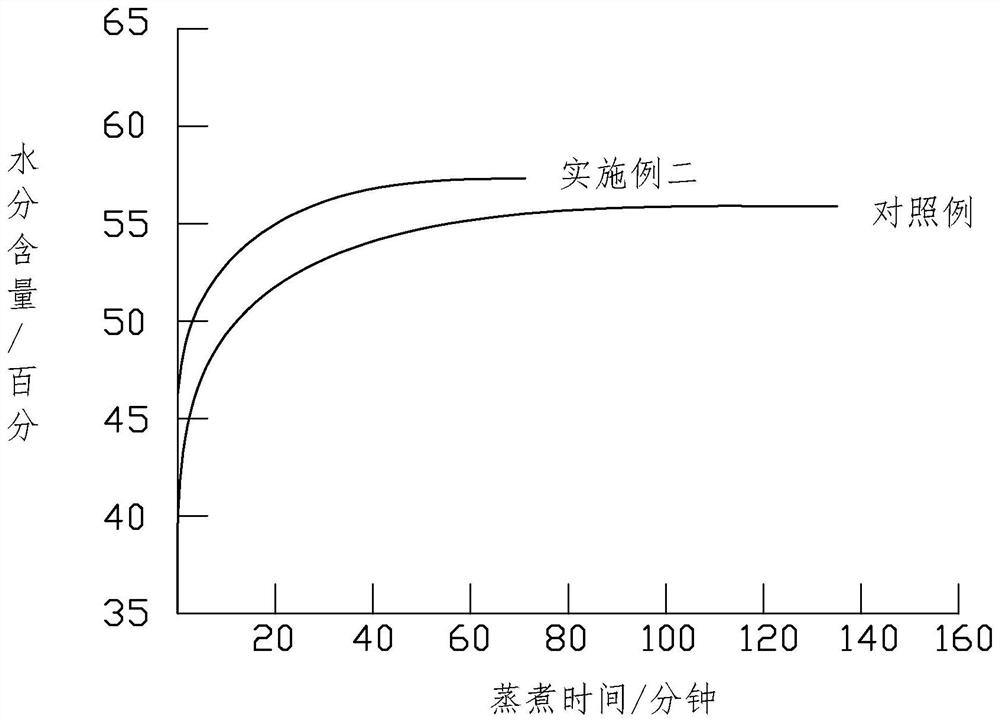

Embodiment 2

[0050] 1) Pretreatment of zong leaves: After washing the zong leaves, put them in boiling water at 100 degrees Celsius for 15 minutes, then take out and soak them in cold water until they are soft and not broken;

[0051] 2) Soaking glutinous rice: Weigh a certain quality of glutinous rice, wash it twice with clean water, add an appropriate amount of water according to the mass ratio of 1:2 to soak, soak for a certain period of time, drain the water with a screen;

[0052] 3) Packaging: Take two zongzi leaves and fold them into a cone and place them in a mold. Add 100g of soaked glutinous rice and tie them with rice noodles; the packaging density of zongzi is 0.81 g / ml; the packaging density of zongzi refers to The bulk density of the zongzi after packaging, the drainage method to measure its volume and calculate its density. ρ=m / V, in the formula: ρ: the packing density of the zongzi; m: the mass of the zongzi; V: the volume of the zongzi measured by the drainage method.

[0053] 4...

Embodiment 3

[0058] 1) Pretreatment of zong leaves: After washing the zong leaves, put them in boiling water at 100 degrees Celsius for 15 minutes, then take out and soak them in cold water until they are soft and not broken;

[0059] 2) Soaking glutinous rice: Weigh a certain quality of glutinous rice, wash it twice with clean water, add an appropriate amount of water according to the mass ratio of 1:2 for soaking, soak for a certain period of time and drain the water with a screen;

[0060] 3) Packaging: Fold two pieces of zongzi leaves into a cone and place them in a mold, add 100g of soaked glutinous rice, and tie them with rice noodles; the packaging density of zongzi is 0.87 g / ml; the packaging density of zongzi refers to The bulk density of the zongzi after packaging, the drainage method to measure its volume and calculate its density. ρ=m / V, in the formula: ρ: the packing density of the zongzi; m: the mass of the zongzi; V: the volume of the zongzi measured by the drainage method.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com