Primary processing method of low-caffeine yellow tea

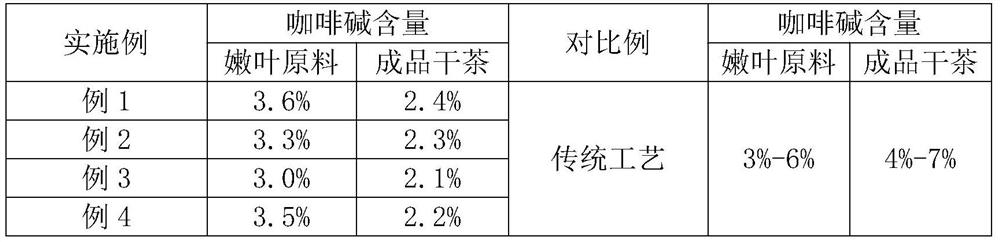

A technology of low caffeine and yellow tea, applied in the direction of pre-extraction tea treatment, theophylline content reduction, etc., can solve the problems of low processing cost, high caffeine content in the sorting of young leaves growing, and achieve low processing cost and sensory quality. Unique, caffeine-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Its specific production method is as follows:

[0026] (1) Harvesting young leaves: select the tea trees with single buds that have been picked before the Ching Ming Festival in Shengfeng Tea Farm, and pick the remaining 3 single young leaves, leaving a petiole of 1-2mm for each leaf;

[0027] (2) Spreading: thinly spread the selected fresh tender leaf raw materials on the indoor screen or withering tank, the thickness of the spreading leaves is 3cm, the amount of spreading leaves is 1.5kg / m2, the spreading time is 12 hours, and every 4 Flip once an hour;

[0028] (3) Finishing: Overturn the stall leaves twice, ventilate for 60 minutes, put them into a continuous high-temperature hot air cleaning machine, put in a thickness of 3cm, fix the time for 2 minutes, and finish the hot air at a temperature of 220°C;

[0029] (4) Stuffy yellow: put the finished leaves into the constant temperature stuffy yellow box while it is hot, the stuffy yellow time is 7 hours, and the stu...

Embodiment 2

[0035] Its specific production method is as follows:

[0036] (1) Harvesting young leaves: 5 days after the picking of single buds in the Qingming Festival of Shengfeng Tea Farm, there are still 3 single young leaves left from the tea trees that have been picked from the single buds, and the petiole of each leaf is 1-2mm;

[0037] (2) Spreading: thinly spread the selected fresh young leaf raw materials on the indoor screen or withering tank, the indoor temperature is controlled at 28°C, the relative humidity is 65%, and there is no direct sunlight into the room. The thickness of the spread leaves is 3cm. The amount of leaves is 1.5kg / m2, and the spreading time is 12 hours, and it is turned every 4 hours in the middle;

[0038] (3) Finishing: Overturn the stall leaves twice, ventilate for 60 minutes, put them into a continuous high-temperature hot air cleaning machine, put in a thickness of 3cm, fix the time for 2 minutes, and finish the hot air at a temperature of 220°C;

[0...

Embodiment 3

[0045] Its specific production method is as follows:

[0046] (1) Harvesting young leaves: After picking a single bud at Shengfeng Tea Farm, randomly pick 10-20 young leaves of tea tree No. 1 to test the caffeine content, and the average content is less than 3.2%. There are 3 single young leaves left in the single-bud tea tree, and the petiole of each leaf is 1-2mm;

[0047] (2) Spreading: thinly spread the selected fresh young leaf raw materials on the indoor screen or withering tank, the indoor temperature is controlled at 28°C, the relative humidity is 65%, and there is no direct sunlight into the room. The thickness of the spread leaves is 3cm. The amount of leaves is 1.5kg / m2, and the spreading time is 12 hours, and it is turned every 4 hours in the middle;

[0048] (3) Finishing: Overturn the stall leaves twice, ventilate for 60 minutes, put them into a continuous high-temperature hot air cleaning machine, put in a thickness of 3cm, fix the time for 2 minutes, and finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com