Preparation method of negative electrode slurry without glue solution, obtained negative electrode slurry and application

A kind of negative electrode slurry, no glue technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problem of high viscosity of glue solution, long-term dispersion, etc., achieve good stability of slurry, reduce equipment cost, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

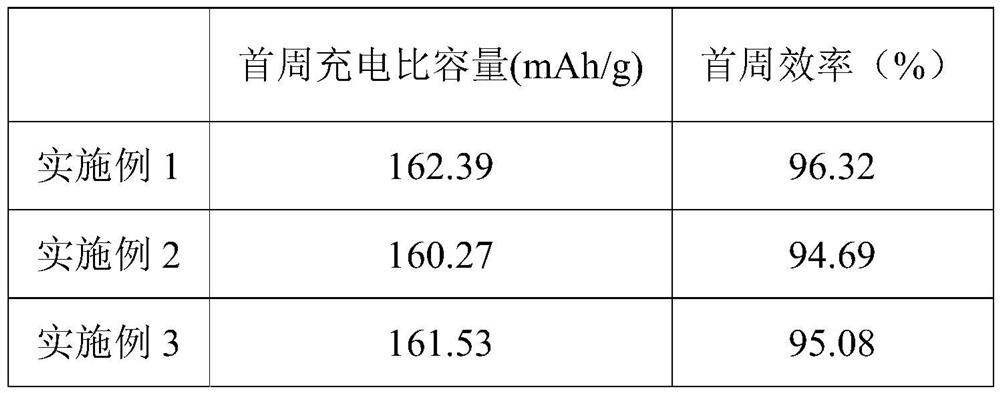

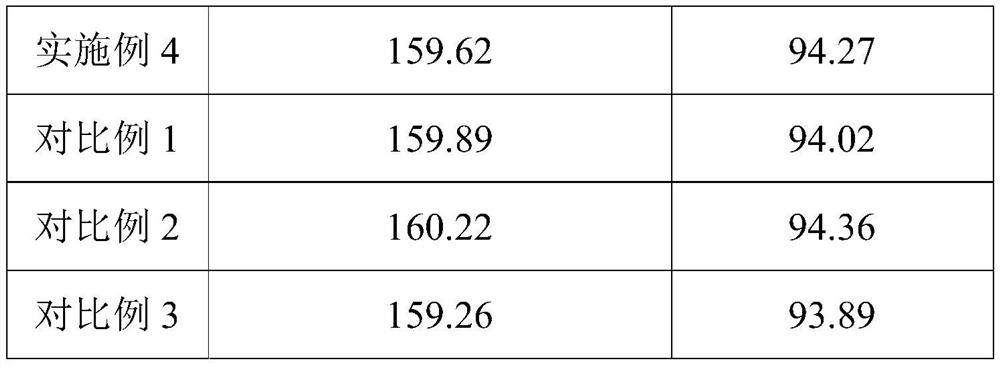

Examples

Embodiment 1

[0054] A kind of preparation method without the negative electrode slurry of glue comprises the following steps:

[0055] (1) 97.5wt% negative electrode active material (graphite of D50=15 μm), 1wt% conductive agent powder (diameter is the SP of 180nm) and the thickener CMC powder of 1.5wt% (particle diameter is D50=75 μm) mixing, Carry out the first stirring and mixing for 20 minutes with a revolution rate of 20 rpm and an autorotation of 200 rpm to obtain a mixed powder;

[0056] (2) Mix the mixed powder with water, and carry out the second stirring and mixing at a speed of 20 rpm and 2000 rpm for 250 min to obtain a slurry with a solid content of 65 wt %;

[0057] (3) mixing the slurry obtained in step (2) with water to obtain a slurry with a solid content of 54wt% and a viscosity of 4461mPa·s;

[0058] (4) Mix the slurry obtained in step (3) with a binder (SBR), the mass ratio of the binder to the thickener CMC powder is 3:1, and the speed is 10rpm in revolution and 600rp...

Embodiment 2

[0060] The difference from Example 1 is that the solid content of the negative electrode slurry in step (3) is adjusted to 40wt%.

Embodiment 3

[0062] A kind of preparation method without the negative electrode slurry of glue comprises the following steps:

[0063] (1) 97wt% negative electrode active material (graphite of D50=10 μm), 1.5wt% conductive agent powder (diameter is the SP of 150nm) and thickener CMC powder (particle diameter is D50=70 μm) of 1.5wt% are mixed, Carry out the first stirring and mixing for 40 minutes with a revolution rate of 5 rpm and an autorotation of 500 rpm to obtain a mixed powder;

[0064] (2) Mix the mixed powder with water, carry out the second stirring and mixing at a speed of 5 rpm and 2500 rpm for 270 min to obtain a slurry with a solid content of 65 wt %;

[0065] (3) mixing the slurry obtained in step (2) with water to obtain a slurry with a solid content of 55wt% and a viscosity of 4600mPa·s;

[0066] (4) Mix the slurry obtained in step (3) with a binder (SBR), the mass ratio of the binder to the thickener CMC powder is 4:1, and the speed is 5rpm in revolution and 1000rpm in ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com