A device and method for cracking heavy oil into coke by catalyzing clay minerals

A clay mineral and coke-forming technology, which is applied in the direction of measuring devices, instruments, investigation stages/state changes, etc., can solve problems such as increasing experimental errors, fewer experimental samples, and flameout at the front of the fire, so as to ensure accuracy and representativeness , accurate analysis of processing methods, and the effect of ensuring rigor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 A device for cracking heavy oil into coke catalyzed by clay minerals

[0045] Such as figure 1 and figure 2 As shown, this embodiment includes a sample preparation system, a separation system, an injection system, an experimental model system, a temperature control system, a pressure control system, an analysis system and a PC terminal; wherein the experimental model system is respectively connected with the sample preparation system, the separation system, and the injection system , The temperature control system, the pressure control system, the analysis system are connected, the separation system is connected with the sample preparation system, the analysis system, the sample preparation system is connected with the injection system, the injection system, the temperature control system and the pressure control system are connected with the PC terminal.

[0046] In this embodiment, the experimental model system includes a high-temperature and high-pressure...

Embodiment 2

[0053] Example 2 A method of cracking heavy oil into coke by catalyzing clay minerals

[0054] This embodiment includes the following steps:

[0055] S1. Separating the oil sample through the separation system to obtain asphaltenes, saturated components, aromatic components and colloids;

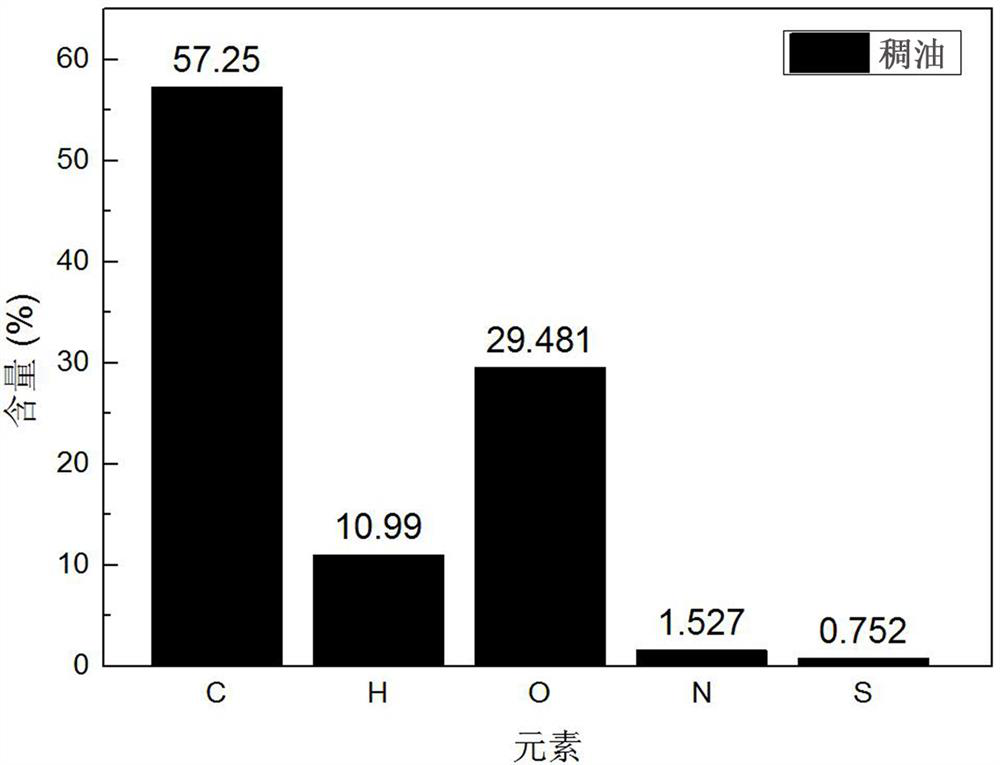

[0056] S2. Select the clay minerals for the experiment, analyze the specific composition and content of the clay minerals through the analysis system, and then combine the clay minerals with oil samples, asphaltene, saturated components, aromatic components and Colloids are evenly mixed to obtain prepared samples;

[0057] S3. Inject the prepared sample and nitrogen into the high-temperature and high-pressure reactor 26 in the experimental model system through the injection system to carry out the cracking reaction, set the reaction temperature through the first high-temperature heating furnace 43, and monitor and control the reaction pressure through the pressure control system , the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com