Automatic liquid dispensing pump

An automatic liquid dispensing and dispensing technology, applied in the field of water treatment, can solve problems such as inability to achieve precise dosing, and achieve the effects of wide application, strong reliability and low operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

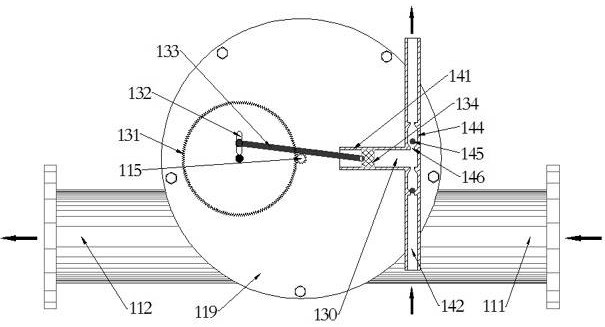

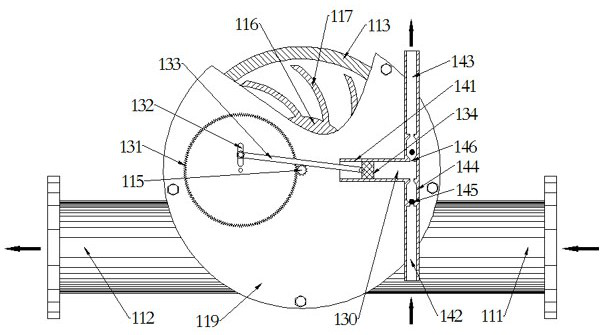

[0034] Please refer to figure 1 , figure 1 Shown is a combination of automatic liquid dispensing pumps, the structure of which is mainly divided into two parts, one part is a water wheel assembly, and the other is a water pump assembly, separated by a volute wall 119 . The water wheel part adopts a wheeled direct flushing water wheel 100, and the water pump part adopts a piston pump 130.

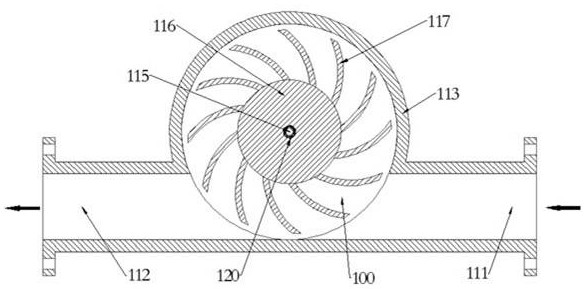

[0035] Please refer to figure 2 , figure 2 Shown is the internal structure of water wheel 100 . The volute 113 is integrated with the main liquid inlet pipe 111 and the main liquid outlet pipe 112 to form the shell of the water wheel 100 . The main liquid inlet pipe 111 and the main liquid outlet pipe 112 are placed on both sides of the volute 113, tangent to the volute 113 and located at the bottom of the volute; the main liquid inlet pipe 111 and the main liquid outlet pipe 112 have the same diameter and are located on the same On the axis to reduce the resistance of the main liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com