Efficient double-circulation desilting system

A double-cycle, high-efficiency technology, applied in waterway systems, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of reduced dredging efficiency and inability to continue dredging work, and achieve the goal of improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

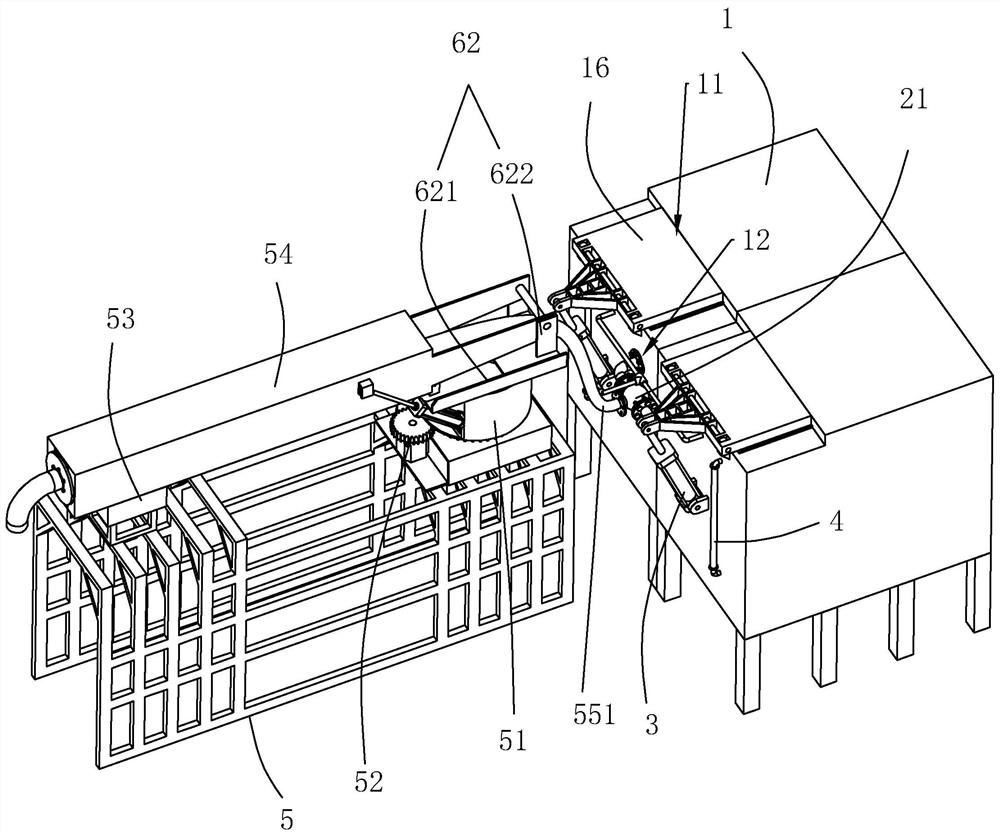

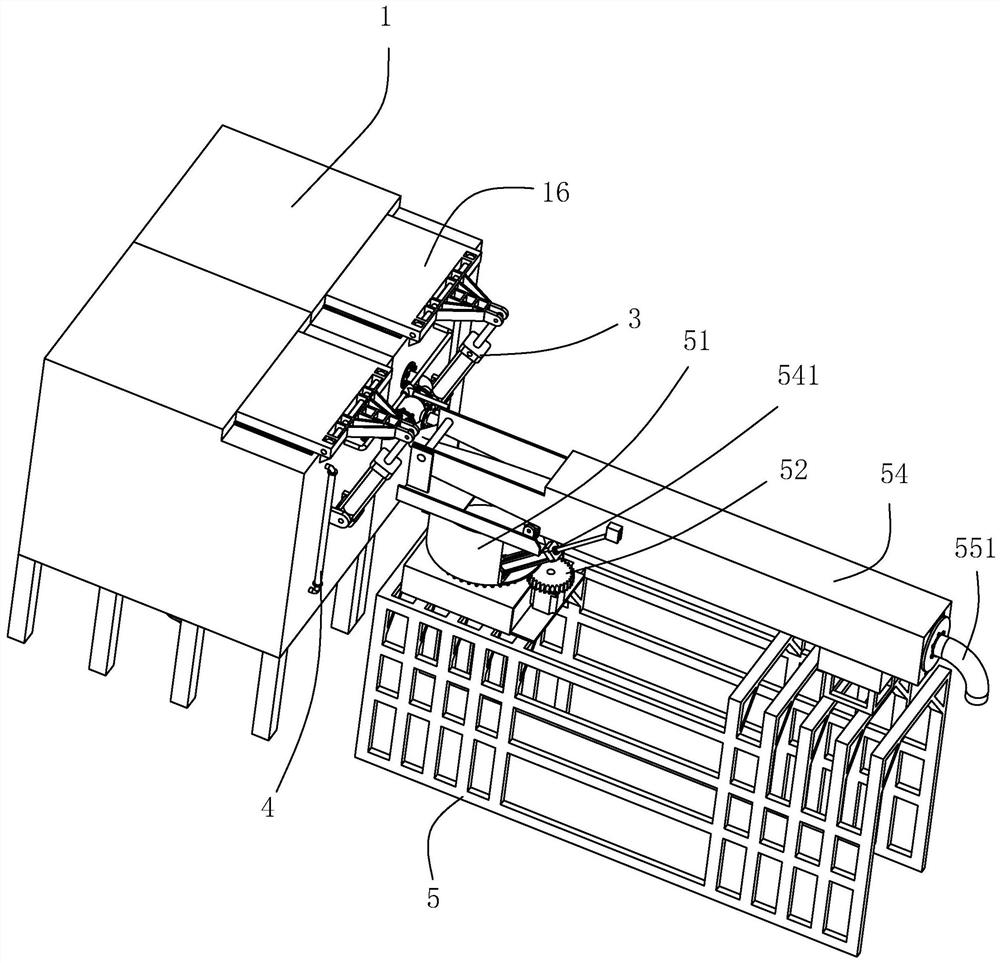

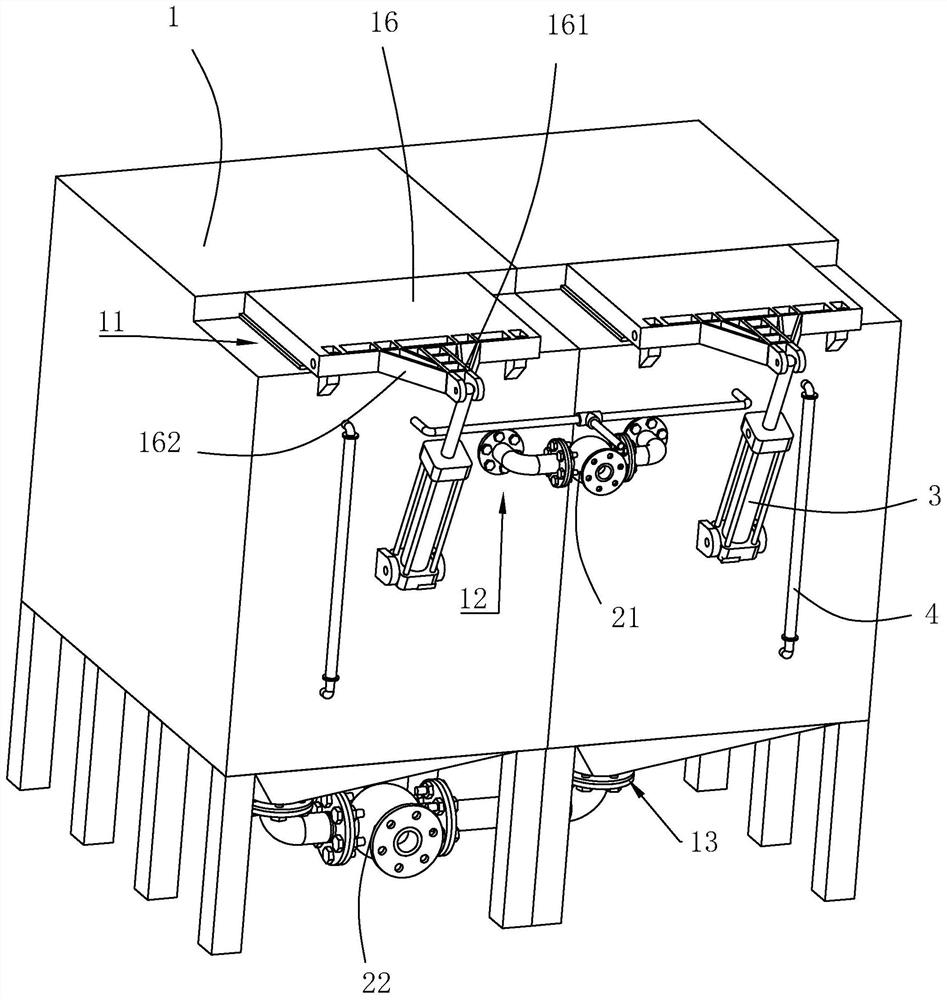

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] like Figure 1 to Figure 2 As shown, a high-efficiency dual-cycle dredging system disclosed by the present invention includes two sets of rectangular-like collection boxes 1 with the same structure, the two sets of collection boxes 1 are arranged side by side, and the top surfaces of the two sets of collection boxes 1 are provided with feeding ports. 11. One side of the same plane is provided with a water inlet 12, and the bottom end is provided with a water outlet 13 (such as image 3 shown); the water inlets 12 of the two sets of collection boxes 1 are jointly installed and connected with the first three-way solenoid valve 21, and the water outlets 13 of the two groups of collection boxes 1 are jointly installed and connected with the second three-way solenoid valve 22 (such as image 3 shown). The first three-way solenoid valve 21 and the second a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com