Woodpecker type bottle preform box filler and bottle preform box filling method thereof

An embryo packing machine and woodpecker technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increasing the workload of packing workers, reducing work efficiency, and damage to preforms, so as to reduce labor intensity and reduce product quality. Damage rate, satisfying the effect of high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings.

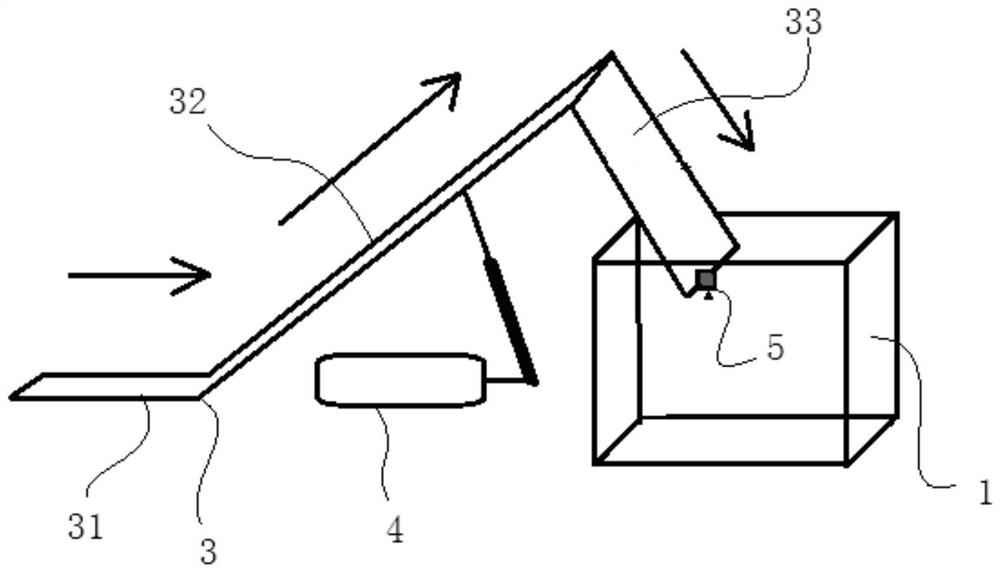

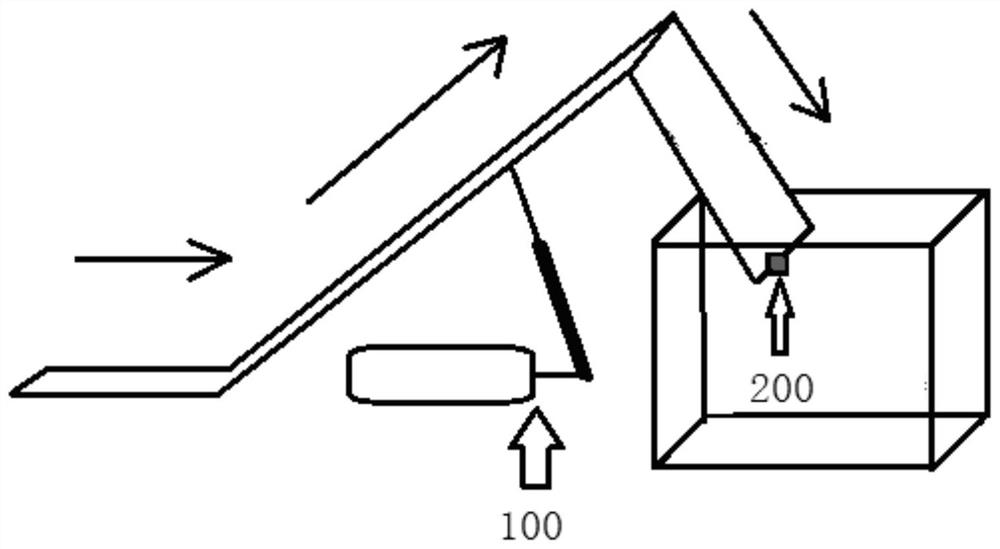

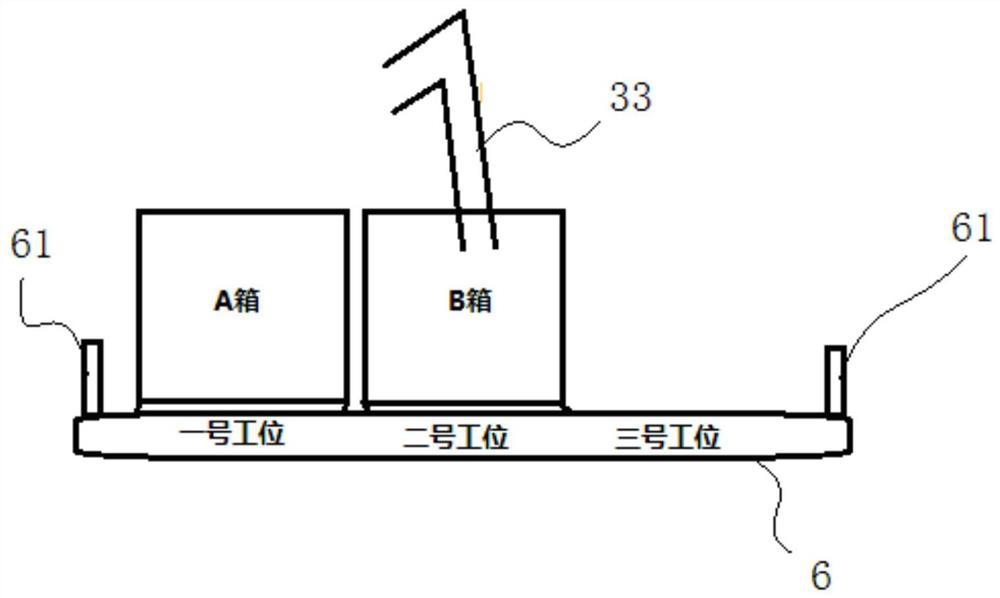

[0036] see figure 1 , image 3 and Figure 4 , The woodpecker type preform box packing machine of the present invention includes: preform box 1, PLC control device 2, preform transmission device 3, hydraulic transmission device 4 and ultrasonic distance measuring sensor 5.

[0037] The preform transfer device 3 is in the shape of a woodpecker and is used to transfer the preform to the preform box 1 . The preform transfer device 3 includes a horizontal part 31 , a slope part 32 and a woodpecker head 33 , the bottom of the slope part 32 is hinged to the horizontal part 31 , and the top of the slope part 32 is fixedly connected to the woodpecker head 33 . The preform transfer device 3 is also laid on the horizontal part 31, the slope part 32 and the woodpecker head 33, and is used for the conveyor belt for transferring the preform; and accepts the control of the PLC con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com