Rice bag handle pressing machine

A pressing machine and rice bag technology, applied in bag making operations, container manufacturing machinery, paper/cardboard containers, etc., can solve problems such as low efficiency, unsatisfactory handle pressing quality, slow feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

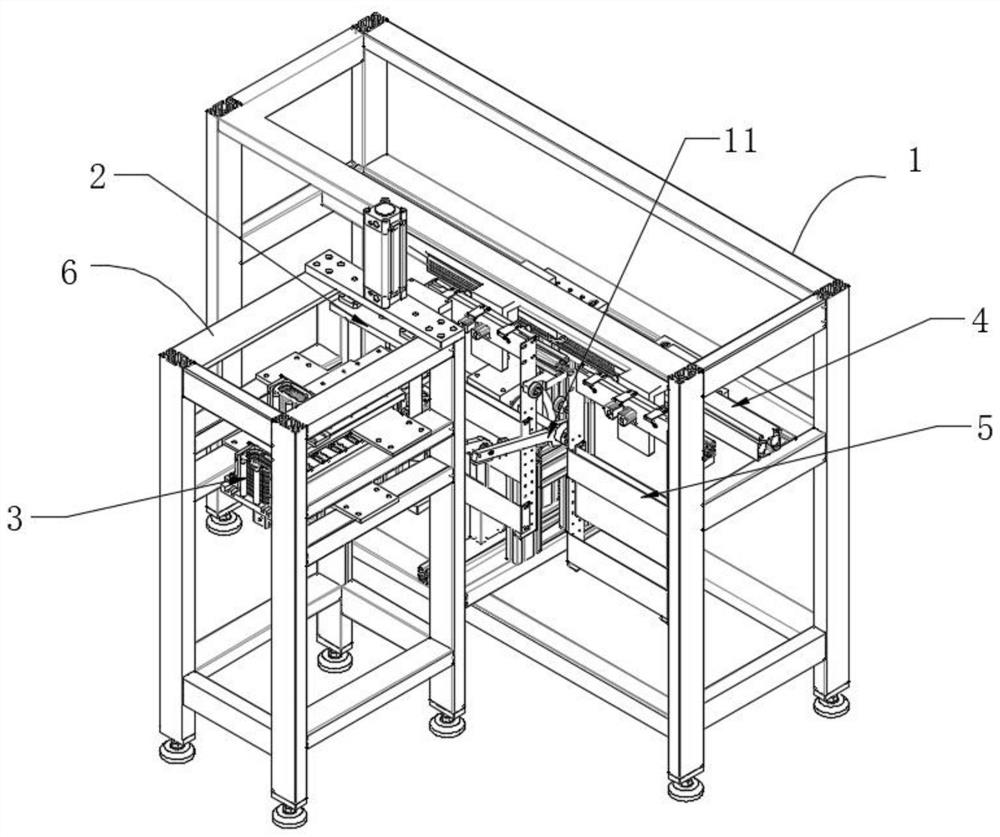

[0035] Embodiment: rice bag handle pressing machine, constitutes as figure 1 As shown, the first frame 1 is included, the first frame 1 is provided with a multi-station mechanism 4, the multi-station mechanism 4 is fixed with a packaging bag supporting device 5, and the multi-station mechanism 4 is provided with a rotating bag release mechanism 11; One side of the first frame 1 is provided with a second frame 6, the second frame 6 is provided with a handle conveying mechanism 3, and one end of the handle conveying mechanism 3 is provided with a handle pressing mechanism 2 .

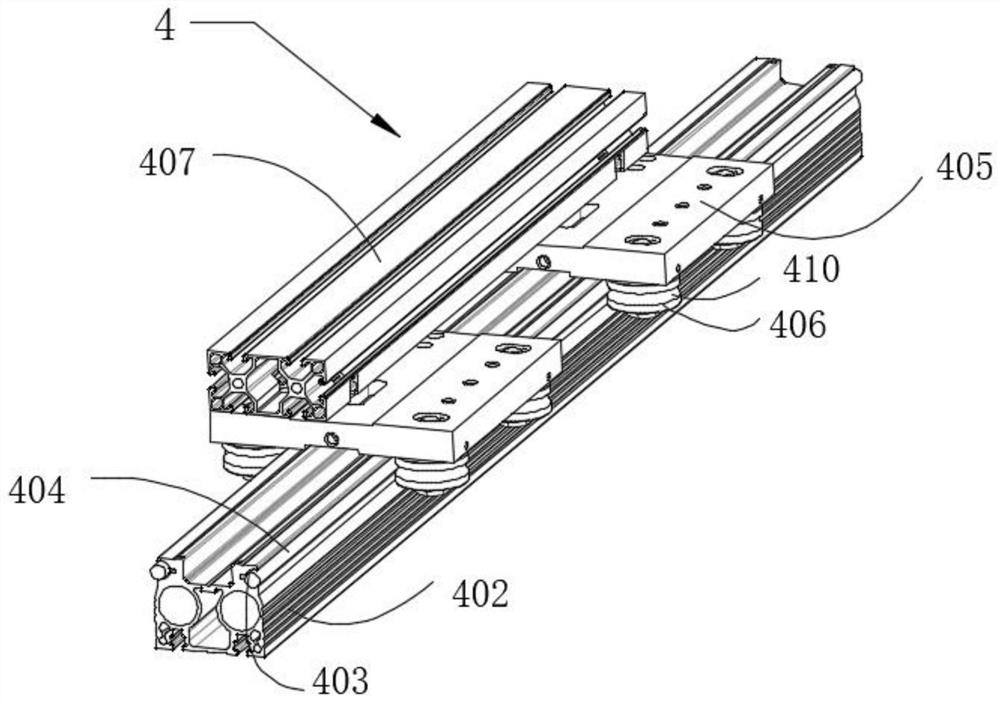

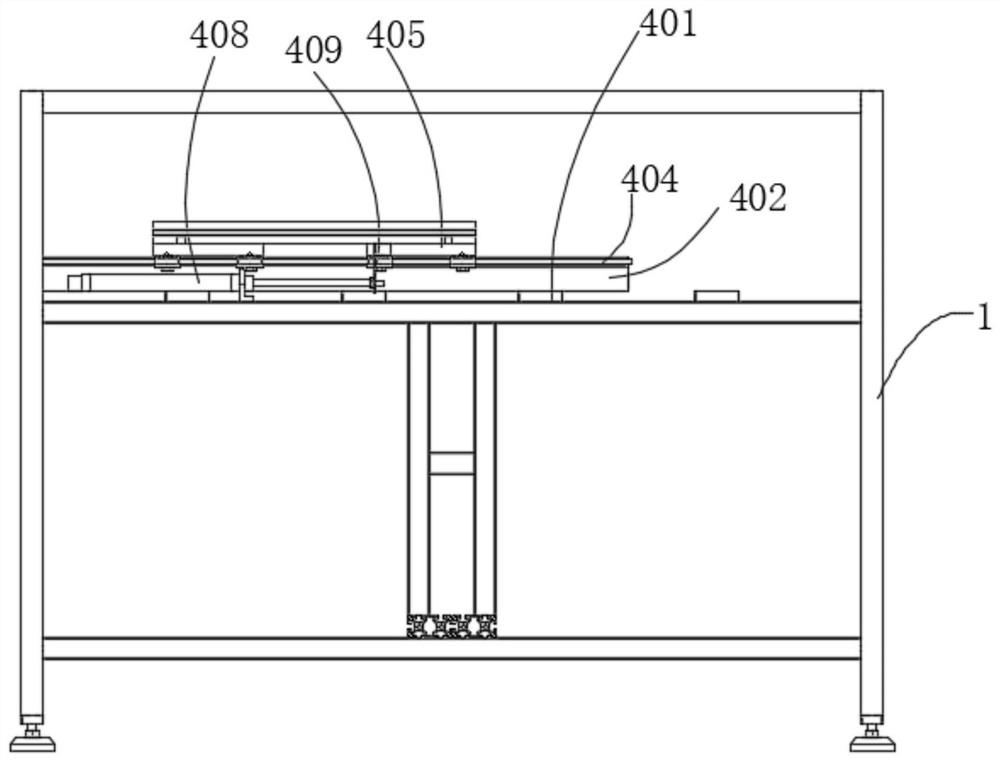

[0036] The multi-position mechanism 4 includes a positioning plate 401 arranged on the first frame 1, such as figure 2 and 3 As shown, the positioning plate 401 is provided with a connecting profile 402, and the two sides of the upper part of the connecting profile 402 are provided with a semicircular groove 403, and a polished rod 404 is clamped in the semicircular groove 403; the connecting profile 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com