A water pump impeller press-fitting device and press-fitting method thereof

A technology for press-fitting devices and water pump impellers, which is applied in metal processing equipment, lubricating compositions, metal processing, etc., can solve problems such as instability, damage to the cooperation between the impeller and the hole shaft, etc., to improve the lubrication effect, reduce frictional resistance, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

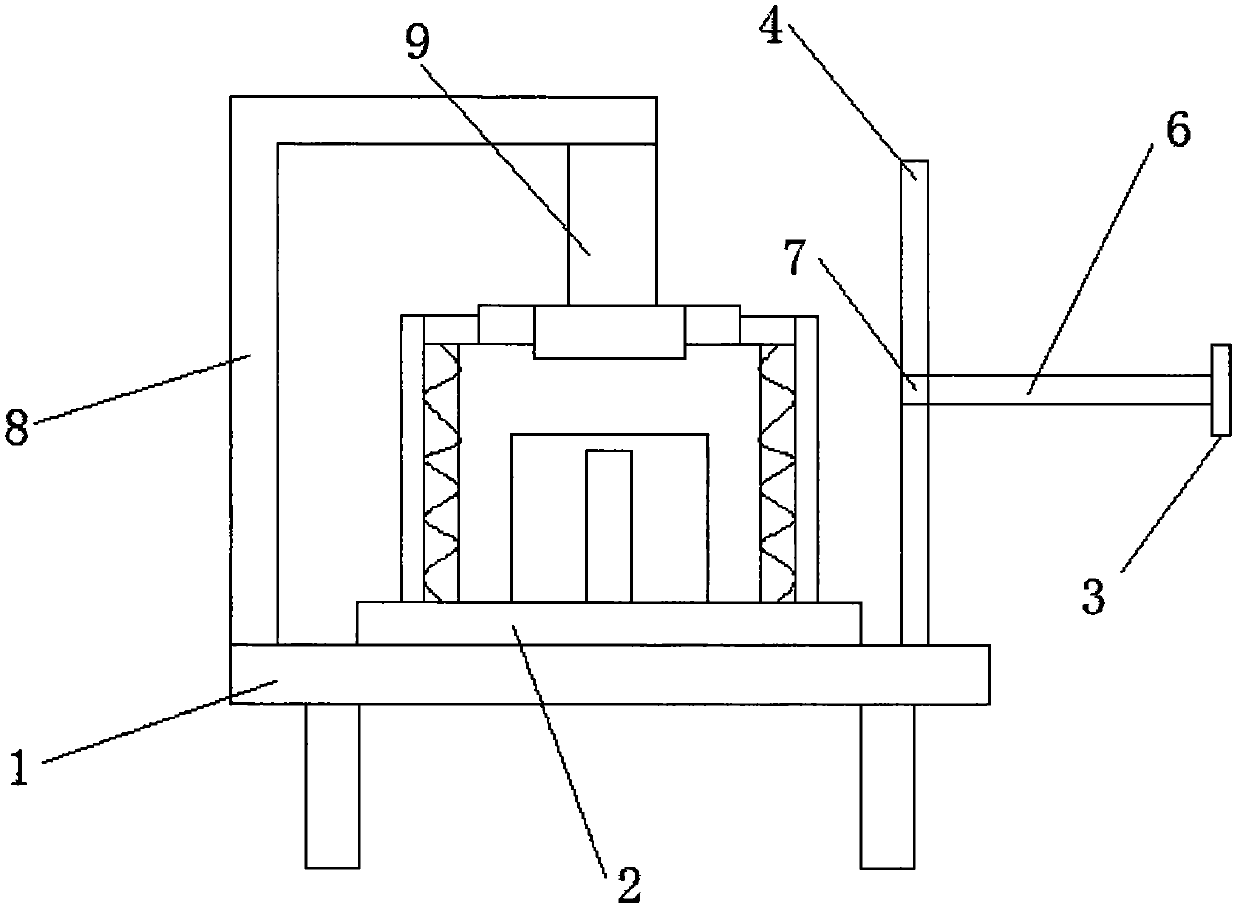

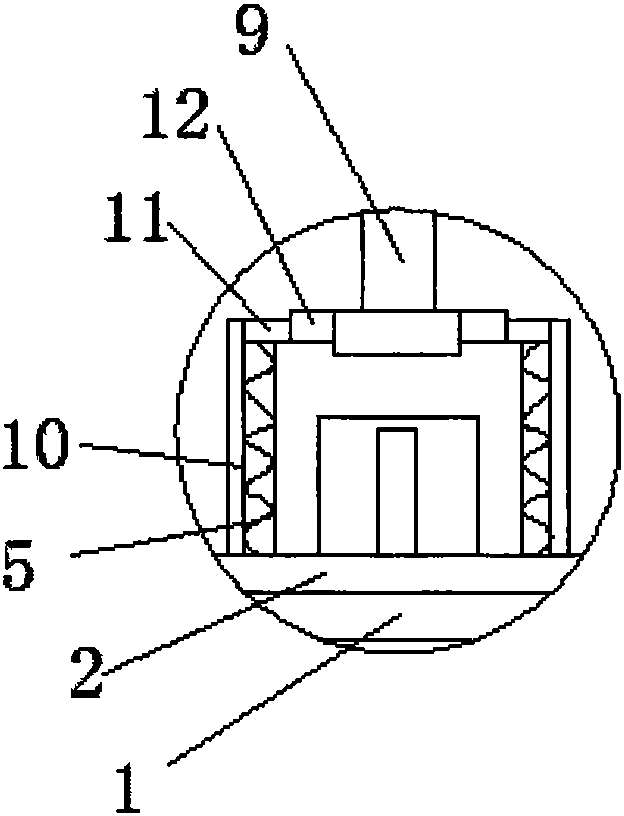

[0020] refer to Figure 1-2 , the present invention will be further explained below in conjunction with specific embodiment.

[0021] In an embodiment, a water pump impeller pressing device proposed by the present invention includes a workbench 1 on which an operation panel 2 is fixedly installed, and a positioning rod 3 is vertically installed directly above the operation panel 2. One of the positioning rods 3 A rotating rod 6 is vertically installed on the side, and the end of the rotating rod 6 away from the positioning rod 3 is fixedly installed with a horizontal bushing 7. The horizontal bushing 7 is movably sleeved with a bracket 4 fixedly connected to the workbench 1. The positioning rod 3 guide devices are installed symmetrically on both sides, and a press-fitting machine is installed directly above the guide device;

[0022] The guide device includes a fixed plate 10 vertically installed with the operation panel 2, a groove is provided on the fixed plate 10, and a sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com