Gear chamber lining press fitting tool

A press-fitting tool and gear chamber technology, applied in the field of gear chamber bushing press-fitting tools, can solve problems such as misalignment of oil holes and high quality risks, and achieve the effects of convenient operation, effective alignment of oil holes, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments, but this does not constitute any limitation to the present invention.

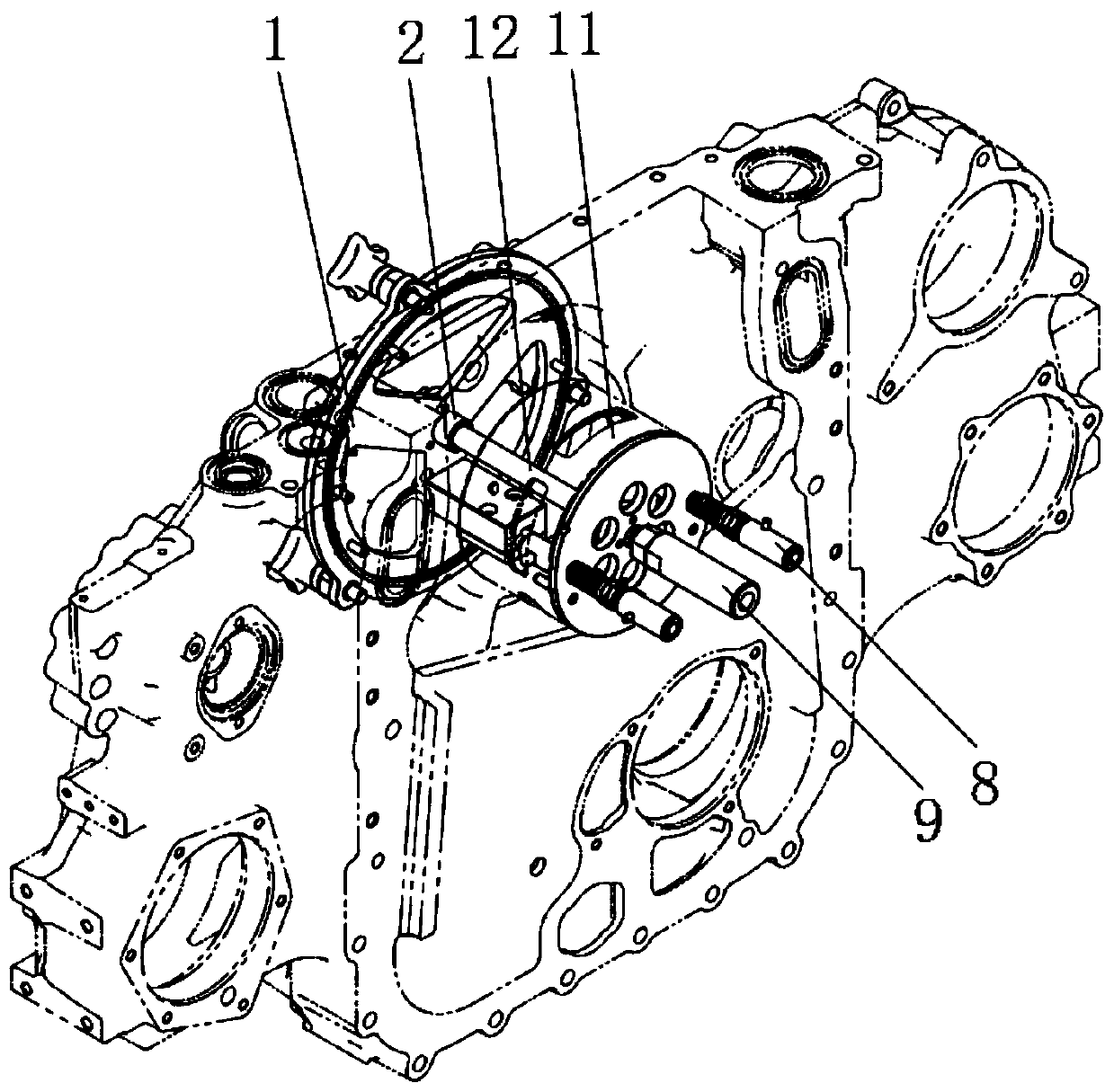

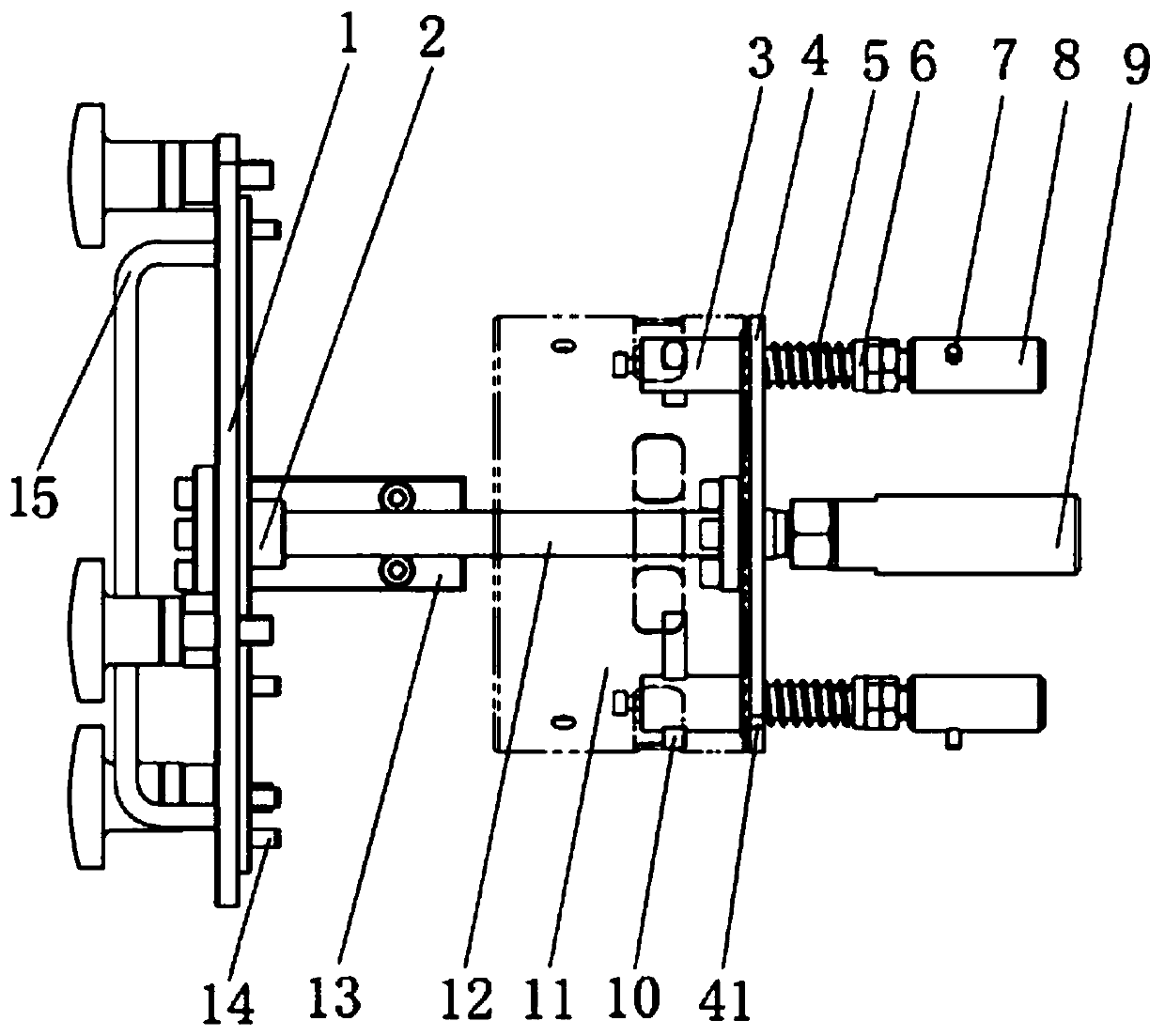

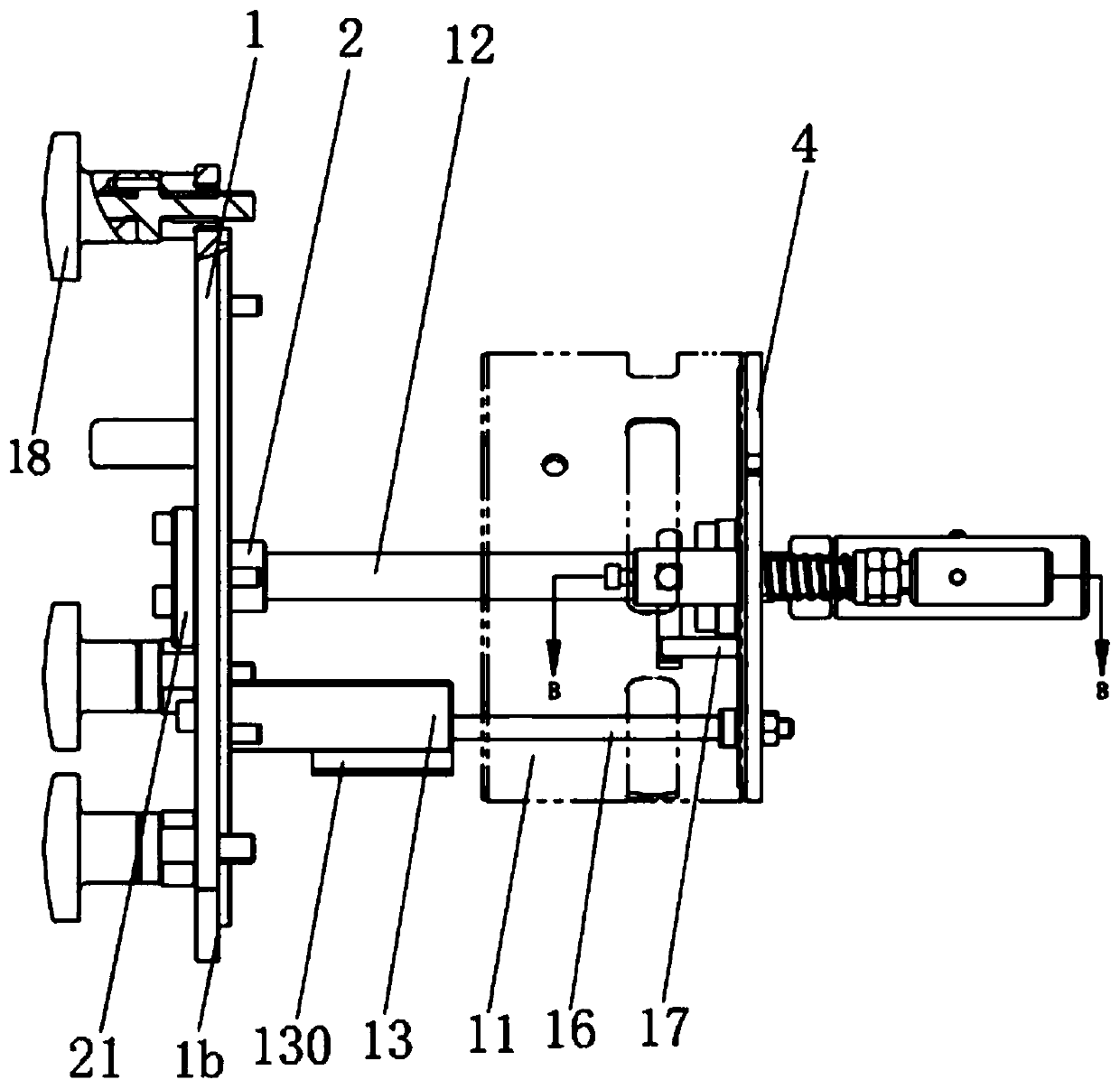

[0028] refer to Figure 1 to Figure 6 As shown, a gear chamber liner pressing tool of the present invention includes a split clamping mechanism and a positioning mechanism. The clamping mechanism includes a phase positioning plate 4 and a gear chamber liner installed on it for clamping the gear chamber liner. 11, the phase positioning plate 4 is provided with a central positioning shaft 12 and a phase positioning pin 16, and the edge of the phase positioning plate 4 is provided with a phase mark notch 41 corresponding to the oil hole of the gear chamber bushing 11, and the positioning mechanism includes a guide The positioning plate 1 is provided with a central guide sleeve 2 and a phase seat 13 on the guide positioning plate 1, the central guide sleeve 2 is detachably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com