Recovering system for plastic casings of waste lead-acid batteries

A technology of plastic shell and recycling system, applied in plastic recycling, battery recycling, waste collector recycling, etc., can solve the problems of salvaging impurities and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

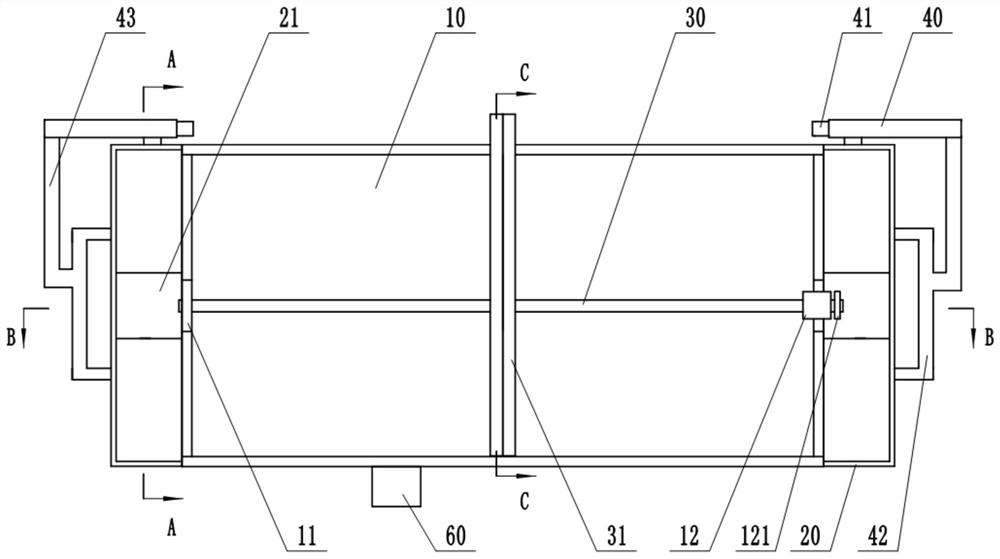

[0031] This embodiment is basically as figure 1 , Figure 4 Shown: the waste lead-acid battery plastic shell recycling system, including a sorting tank 10, a water pump 60, an impurity separating device and two stirring mechanisms. The water pump 60 is installed on the side wall of the sorting tank 10. One side of the water pump 60 is connected with a water inlet pipe, and the other side is connected with a drain pipe. A one-way drain valve is installed on the drain pipe. , the one-way drain valve opens automatically. The drainage pipe is connected with a plurality of drainage branch pipes connected to the bottom of the sorting tank 10, and a filter screen is provided at the connection between the drainage branch pipe and the sorting tank 10, and the filter screen can effectively prevent battery casing fragments from entering the drainage branch pipe, causing the drainage branch pipe to be damaged. clogged.

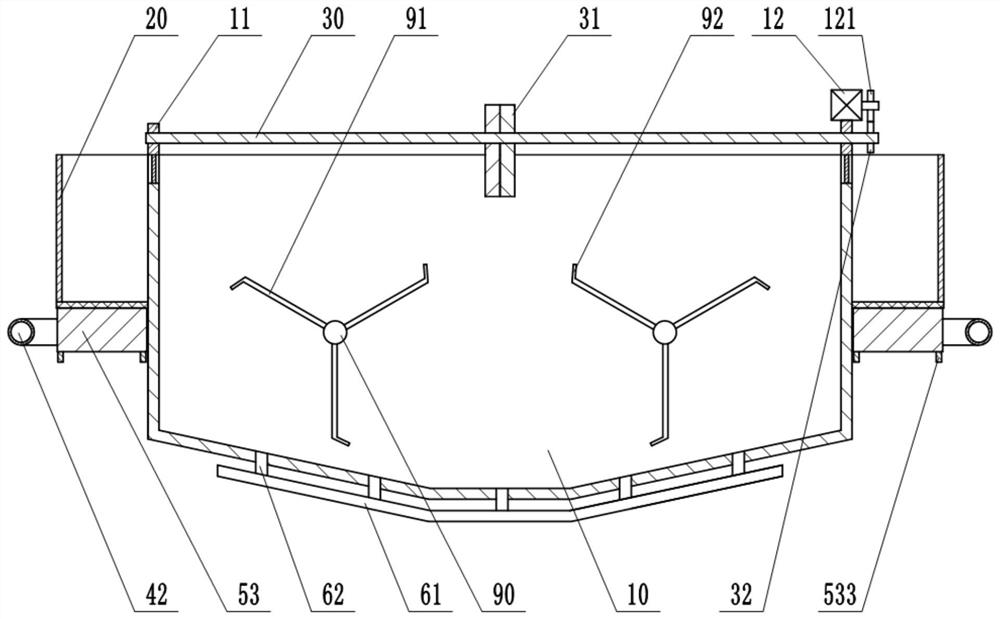

[0032] combine image 3 As shown, two stirring mechanisms are re...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is: the control mechanism of this embodiment is different from Embodiment 1, such as Figure 5 As shown, in this embodiment, the control mechanism includes a one-way bearing and a winding shaft 70 that is rotatably connected to one side of the sorting tank 10, the inner ring of the one-way bearing is fixed on the winding shaft 70, and the winding shaft 70 and the sorting tank 10 are connected with coil springs. A cylinder body 80 is communicated between the two piston cylinders 50 in a sealing mechanism, and a moving cylinder 81 is communicated with the cylinder body 80 , and a bar column 811 is slid and sealed in the moving cylinder 81 . A coil 72 is wound on the winding shaft 70, and one end of the coil 72 is connected to the bar column 811. When the winding shaft 70 rotates in a fixed direction, the winding shaft 70 can drive the bar column 811 to move through the pull wire on the coil 72. A transmission gear 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com