Mechanical arm with good clamping effect

A technology of manipulators and power mechanisms, applied in the field of manipulators, can solve problems such as low work efficiency, high labor intensity, and high labor costs, and achieve the effects of reducing the incidence of accidents, stable sliding, and obvious clamping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

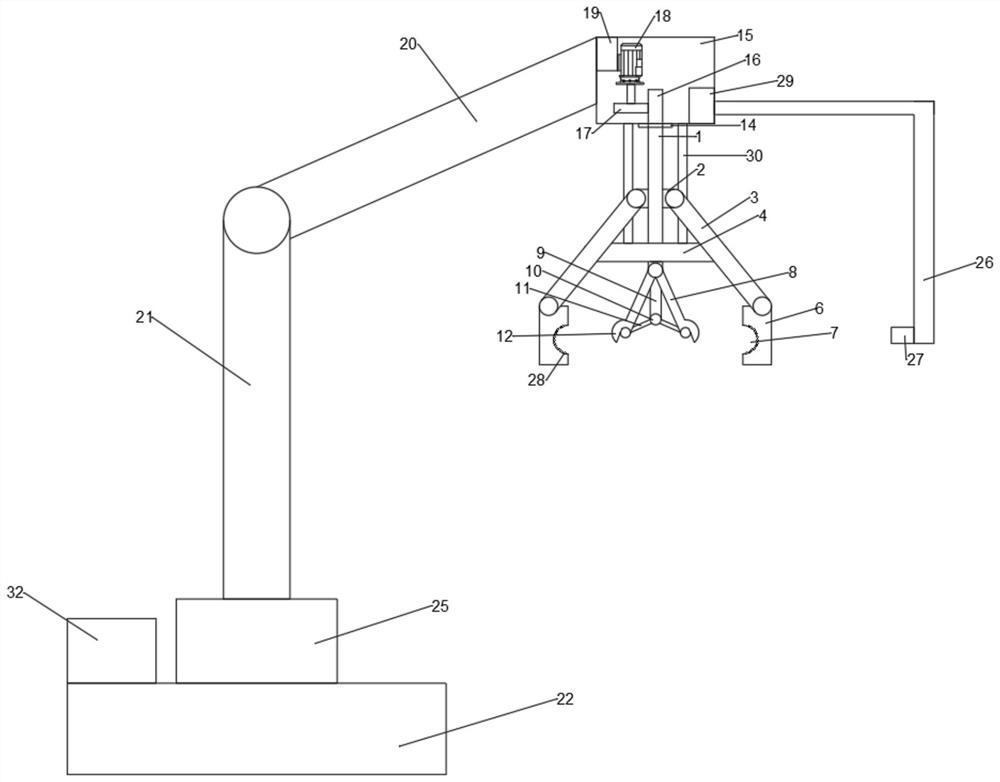

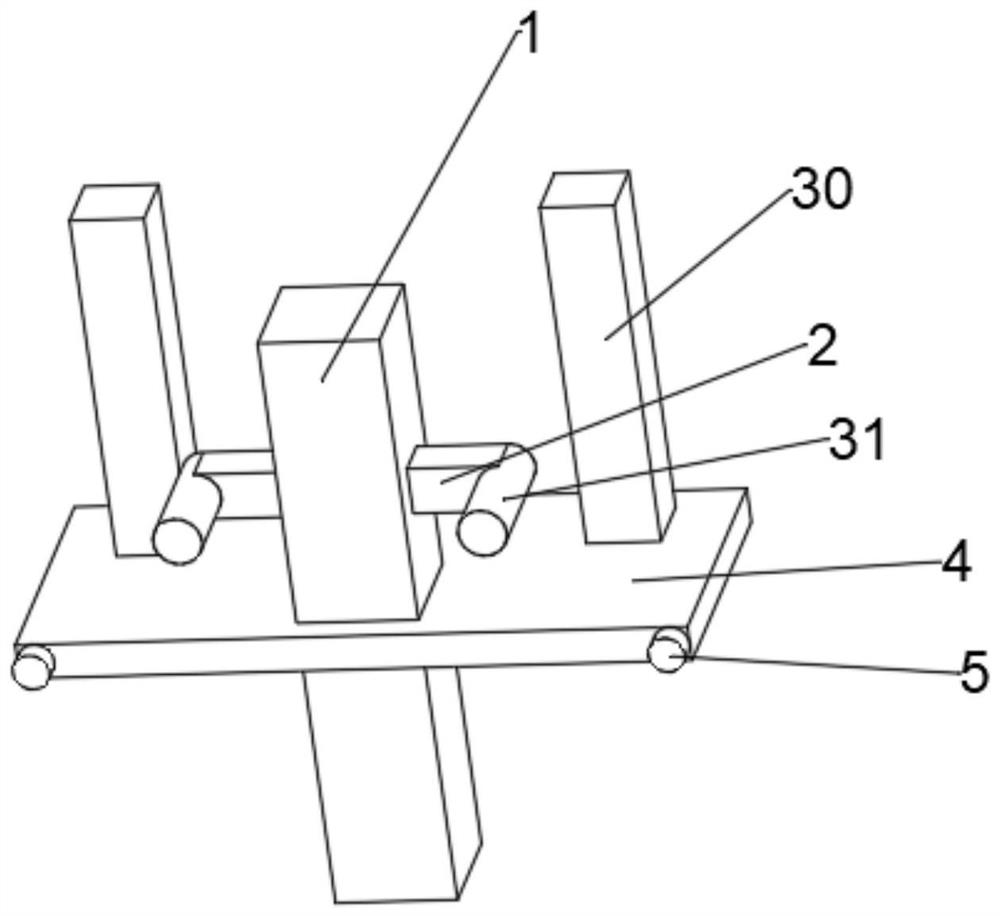

[0034] refer to Figure 1 ~ Figure 4, a manipulator with good clamping effect, comprising a power box 15, a first sliding rod 1 is slidably connected to the bottom of the power box 15, and a bolt on the first sliding rod 1 is connected with a first fixed rod 2, and the first fixed rod 2 Both ends of the left and right sides are bolt-connected with a second protruding platform 31, the front side of the second protruding platform 31 is connected with a second sliding rod 3, and the end of the second sliding rod 3 away from the second protruding platform 31 is bolted with a card. Block 6, the inner side of the block 6 is provided with a card slot 7, the end of the first sliding rod 1 away from the power box 15 is rotatably connected to a swing rod 8, and the end of the swing rod 8 far away from the first slide rod 1 is bolted to an internal block 12 The center of the inner block 12 is rotatably connected with a first connecting rod 11, and the end of the first connecting rod 11 a...

Embodiment 2

[0042] refer to Figure 5 , a manipulator with good clamping effect. Compared with Embodiment 1, the present embodiment is provided with a running mechanism under the bottom plate 22, the running mechanism includes a rolling wheel 23 and a brake plate 24, and the bottom four corners of the bottom plate 22 are bolted. Rolling wheel 23, the bolt on the rolling wheel 23 is connected with brake plate 24, utilizes rolling wheel 23 to make device can move freely, makes it can move in clamping process, plays the effect of carrying, utilizes brake plate 24 to make device When the clamping is not completed, the stability of the device is maintained, the clamping efficiency is improved, and its applicability is increased.

[0043] Working principle: use the rolling wheel 23 to make the device move freely, so that it can move during the clamping process, and play the role of transportation; use the brake plate 24 to keep the device stable when the clamping is not completed, and improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com