A kind of wrapping forming process of side wall of metal shell

A metal shell and forming process technology, which is applied in the field of wrapping forming process of the side wall of the metal shell, and can solve problems such as break and gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A process for forming a circle around a side wall of a metal shell, which comprises the following steps:

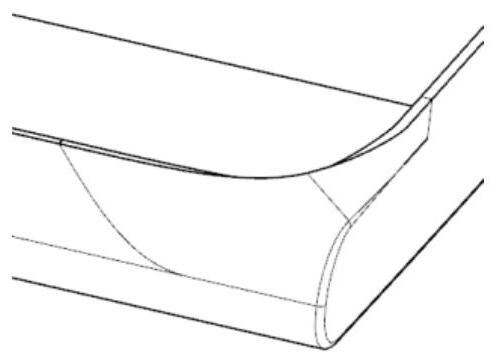

[0032] (1) 90-degree bending forming: the thin material sheet is fixed on the 90-degree forming mold and then bent, such as figure 1 In the case shown, the size of the outer fillet at the bend is 90 degrees;

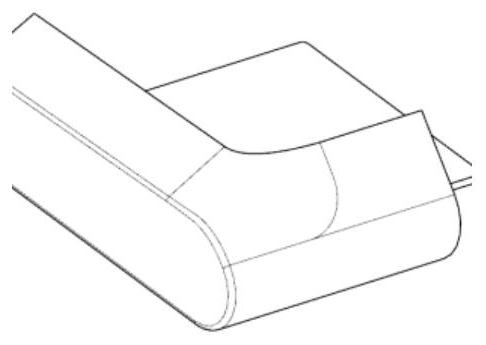

[0033] (2) Oblique 45-degree molding: Fix the outer shell that has been bent at 90 degrees on the oblique 45-degree molding die and push the molding. The edge material flows to both sides, so that the corners are in a fan-shaped structure, resulting in figure 2 Slanted 45 degree forming prefab shown;

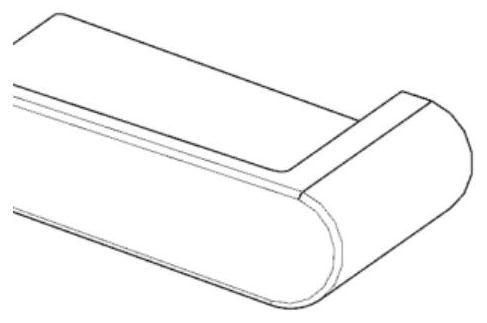

[0034] (3) 150-degree rounding molding: fix the inclined 45-degree molding prefabricated parts on a 150-degree forward mold for pre-rounding horizontal side push molding, so that the two side walls except the corners reach 150-degree rounding molding, and the following results are obtained. image 3 The shown 150-degree rounded prefabricated part, wherein t...

Embodiment 2

[0037] A process for forming a circle around a side wall of a metal shell, which comprises the following steps:

[0038] (1) 90-degree bending forming: fix the thin sheet on the 90-degree forming die and bend it to obtain the following figure 1 In the case shown, the size of the outer fillet at the bending position is 90 degrees, wherein the case is made of aluminum sheet, and the thickness of the case is 0.8mm, 1.0mm or 1.2mm;

[0039] (2) Oblique 45-degree molding: Fix the outer shell that has been bent at 90 degrees on the oblique 45-degree molding die and push the molding. The edge material flows to both sides, so that the corners are in a fan-shaped structure, resulting in figure 2 Slanted 45-degree molding preforms shown, such as figure 2 shown;

[0040] (3) 150-degree rounding molding: fix the inclined 45-degree molding prefabricated parts on a 150-degree forward mold for pre-rounding horizontal side push molding, so that the two side walls except the corners reach...

Embodiment 3

[0043] A process for forming a circle around a side wall of a metal shell, which comprises the following steps:

[0044] (1) 90-degree bending forming: fix the thin sheet on the 90-degree forming die and bend it to obtain the following figure 1 In the case shown, the size of the outer fillet at the bending place is 90 degrees, the radius of the outer fillet is 0.5-0.6mm, and the radius of the outer fillet is preferably 0.5mm, wherein the outer shell is made of aluminum material plate. Made, the thickness of the shell is 0.8mm, 1.0mm or 1.2mm;

[0045] (2) Oblique 45-degree molding: Fix the outer shell that has been bent at 90 degrees on the oblique 45-degree molding die and push the molding. The edge material flows to both sides, so that the corners are in a fan-shaped structure, resulting in figure 2 Slanted 45 degree forming prefab shown;

[0046] (3) 150-degree rounding molding: fix the inclined 45-degree molding prefabricated parts on a 150-degree forward mold for pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com