Dye filtering device for textile production

A filter device and dye technology, which is applied in the field of textile production, can solve the problems of dye filter influence, device blockage, etc., and achieve the effect of improving filter efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

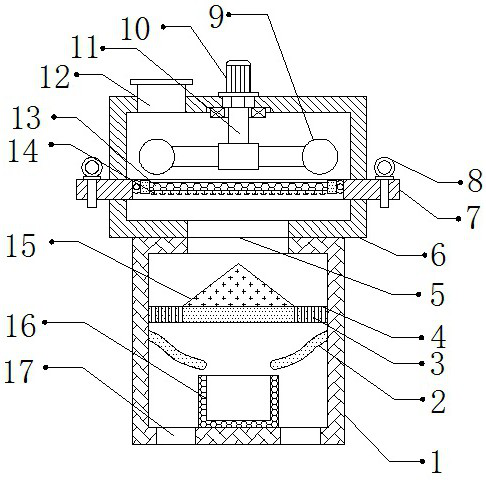

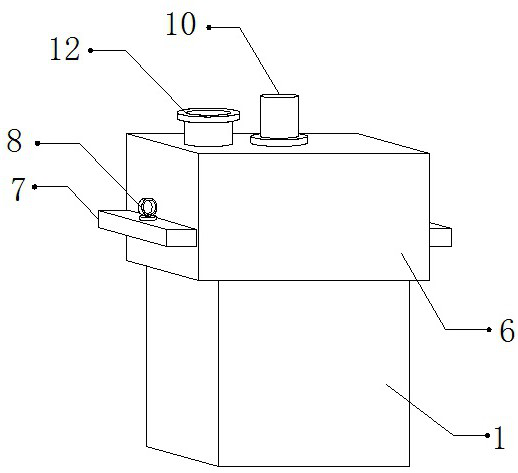

[0026] refer to Figure 1-2 , a dye filter device for textile production, comprising a stirring box 6, a feed pipe 12 is arranged on one side of the top outer wall of the stirring box 6, a rotating shaft 11 is rotatably connected to the top inner wall of the stirring box 6 through a bearing, and the bottom outer wall of the rotating shaft 11 The stirring shaft 9 is connected by bolts, the top outer wall of the stirring box 6 is connected with a motor 10 by bolts, and one end of the output shaft of the motor 10 is connected with the rotating shaft 11 by bolts, the outer walls of both sides of the stirring box 6 are provided with sockets, and A pull-out plate 7 is plugged between the two sockets, jacks are provided on both sides of the top outer wall of the draw-out plate 7, and a latch 8 is plugged into the inner walls of the two jacks, and the top outer wall of the pull-out plate 7 is provided with There is a fixed opening, and the inner wall of the fixed opening is connected ...

Embodiment 2

[0030] refer to image 3 , a dye filter device for textile production. Compared with Embodiment 1, the bottom outer wall of the support plate 3 is connected with an electric telescopic rod 18 by bolts, and the bottom outer wall of the electric telescopic rod 18 is connected with a pressure plate 19 by bolts. A cotton block 20 is bonded to the bottom outer wall of the pressing plate 19 .

[0031] Working principle: when in use, the dye is filled into the stirring box 6 through the feed pipe 12, the motor 10 is started, and the motor 10 will drive the rotating shaft 11 to rotate, so that the dye is stirred through the stirring shaft 9, and the dye is passed through the filter 13 The dye is filtered, and at the same time, the barb 14 can be used to clean up the floating matter doped in the dye, so as to prevent the floating matter doped inside the dye from affecting the filtration of the dye, and the filtered dye will enter through the port 5 into the Inside the filter box 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com