Elevator cable butt joint structure

A technology of elevator cables and giving way slots, which is applied in the directions of cable joints, conductive connections, circuits, etc., can solve problems such as disconnection, and achieve the effects of ensuring safety, simple and convenient connection, and high assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

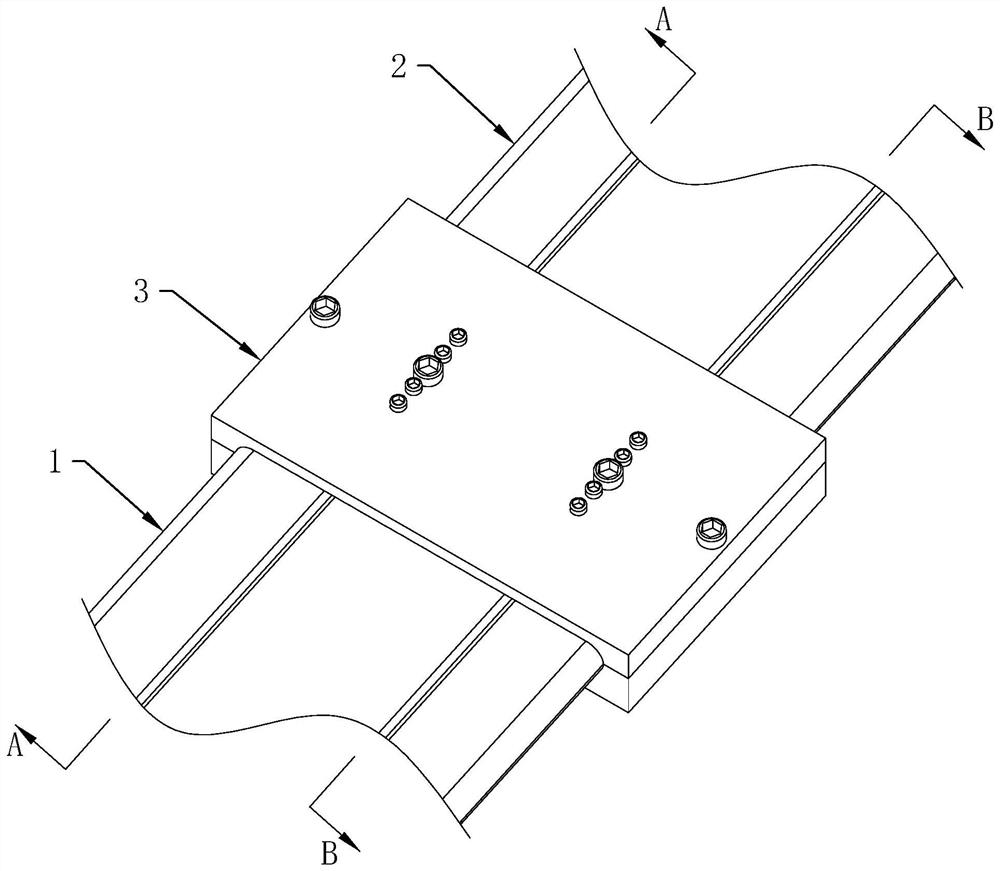

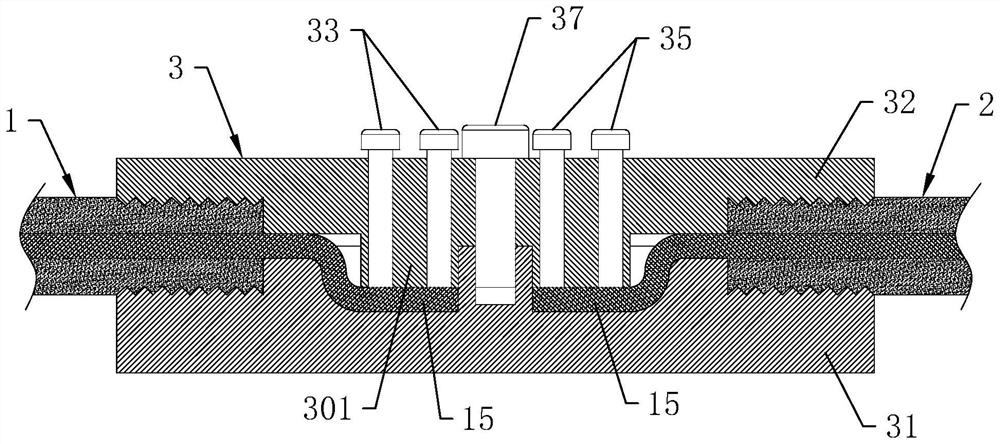

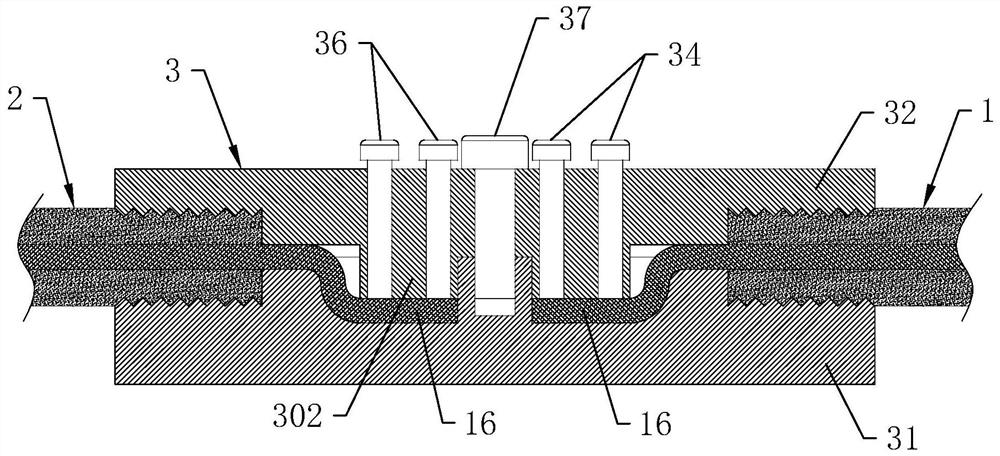

[0023] like figure 1 , Figure 5 and Figure 6 As shown, an elevator cable docking structure according to the present invention includes a first elevator cable 1 and a second elevator cable 2, and the first elevator cable 1 and the second elevator cable 2 include an insulating sheath 11 and a left wire group 12 , middle wire group 13, right wire group 14, left steel wire 15, right steel wire 16, described left wire group 12, middle wire group 13, right wire group 14 are arranged side by side, and described left steel wire 15 is arranged in left wire group 12, Between the middle wire group 13, said right steel wire 16 is arranged between the middle wire group 13, the right wire group 14, for realizing the purpose of the present invention, as Figure 1 to Figure 4 As shown, also includes docking assembly 3, wherein, as Figure 4 and Figure 7As shown, the splicing assembly 3 includes a limit seat 31, a limit cover 32, a first locking screw 33, a second locking screw 34, a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com