Construction method for earth pressure balance shield to pass through large-diameter sewage main pipe underground

An earth pressure balance shield and construction method technology, which is applied in the fields of earthwork drilling, underground chambers, utilization of re-radiation, etc., can solve the problems of difficult construction, high risk, economic loss, etc., so as to reduce construction difficulty and ensure Safe and control the effect of settlement and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

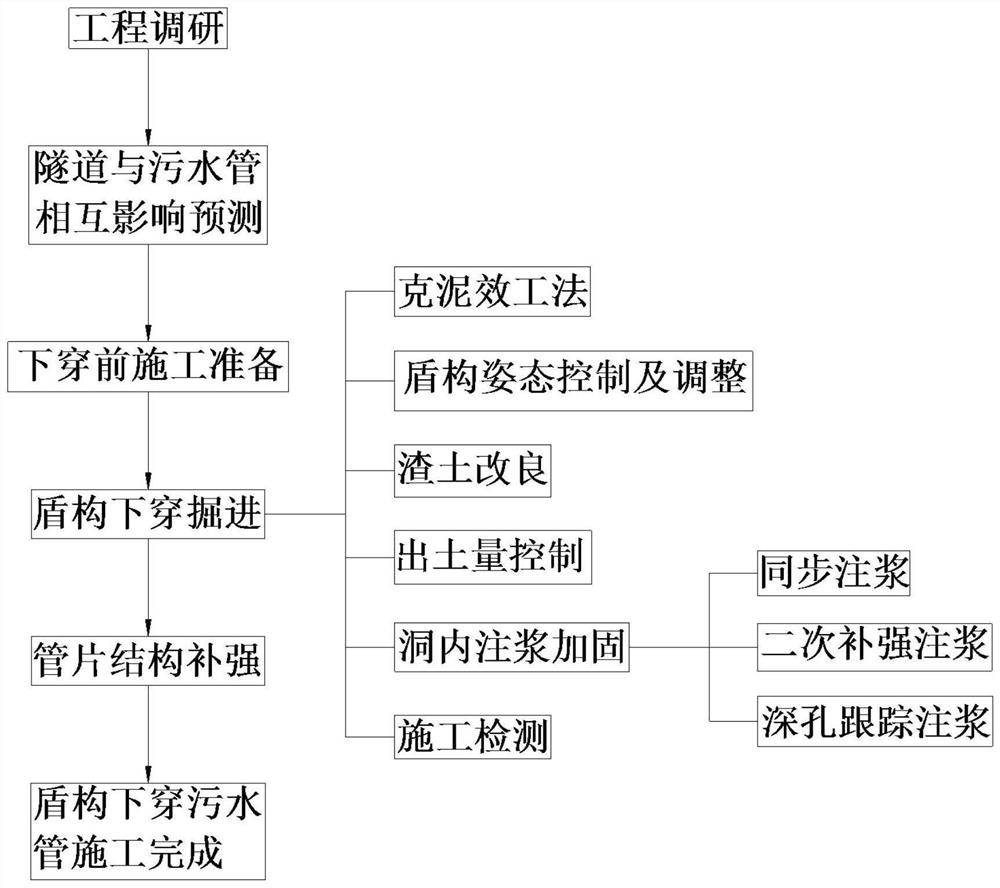

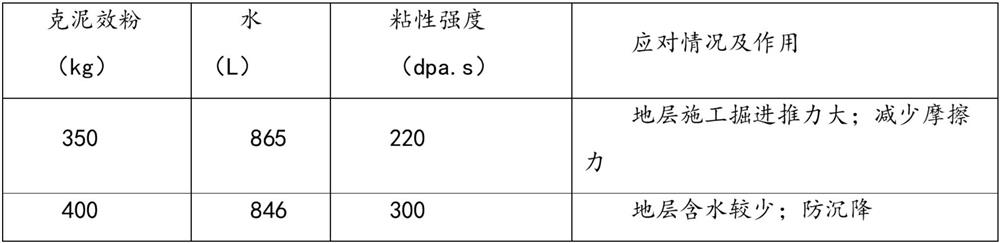

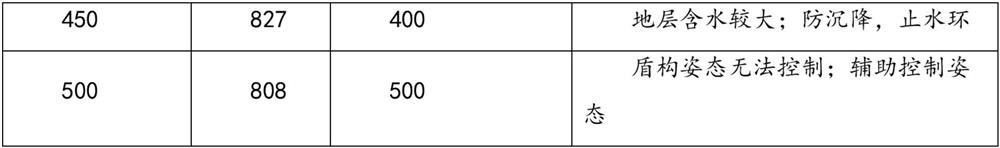

[0034] Such as figure 1 As shown, the construction method of earth pressure balance shield tunneling through large-diameter sewage main pipes. Before construction, a detailed investigation of the sewage pipes within the scope of influence of the shield construction is carried out, mainly including the completion data of the sewage pipes, the design data of the interval tunnel and the surrounding areas of the site. environment, in order to grasp the construction risk of the shield passing through the sewage pipe; considering that the settlement of the sewage pipe caused by construction is closely related to the stratum, the stratum-structure model is used for deformation analysis to simulate the stress and deformation of the sewage pipe, and theoretically determine the shield. The safety of tunneling through the sewage pipe of the structure; set up a 60m experimental section before the tunneling, comprehensive statistical analysis of earth pressure, speed, thrust, torque, grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com