Mechanical high-efficiency transferring device based on intelligent manufacturing

An intelligent manufacturing and high-efficiency technology, applied in the field of high-efficiency mechanical transfer devices, can solve problems that affect the efficiency of workpiece processing and production, affect the accuracy of grasping, and the position is prone to deviation, so as to improve efficiency, ensure the effect, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

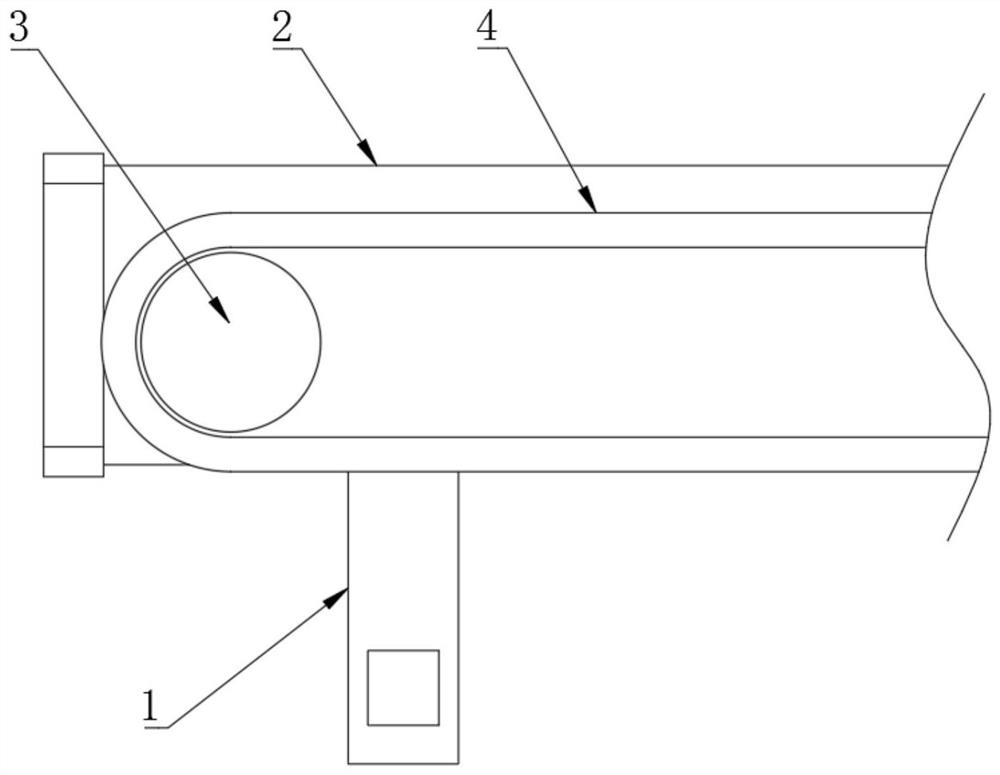

[0043] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a mechanical high-efficiency transfer device based on intelligent manufacturing, including a chassis 1, the top of the chassis 1 is fixedly connected to a fixed frame 2, and the adjacent end of the fixed frame 2 is symmetrically rotatably connected to a second One rotating shaft 3, the outer ends of the two first rotating shafts 3 are sleeved with the first transmission belt 4, one end of the fixed frame 2 is fixedly connected with the rotating motor 5 at the position corresponding to the first rotating shaft 3, and the output shaft of the rotating motor 5 is connected to the first One end of the rotating shaft 3 is fixedly connected, and the tops of the two fixed frames 2 are symmetrically fixedly connected with a material guide mechanism 6. The material guide mechanism 6 includes a mounting seat 601, a notch 602, a positioning pin 603, a material guide plate 604, an embedded gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com