Control terminal-based cab convenient for seat adjustment and used for engineering machinery

A technology for construction machinery and cabs, applied in the field of cabs, can solve problems such as difficulty in taking a good rest, and achieve the effect of reducing driving fatigue and simple and quick operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

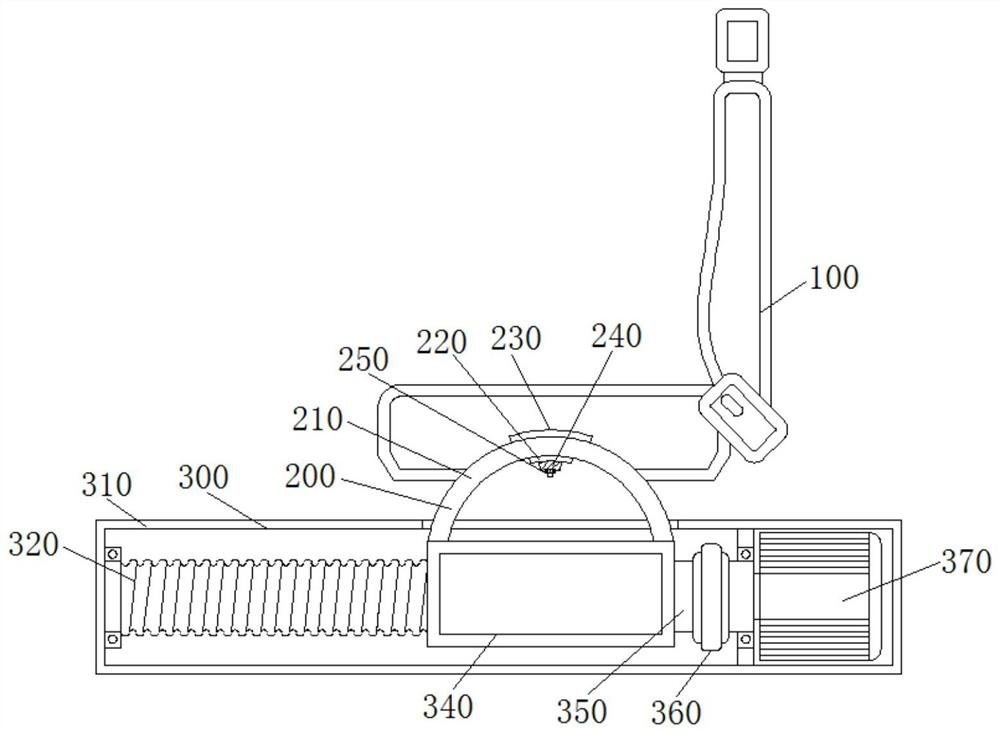

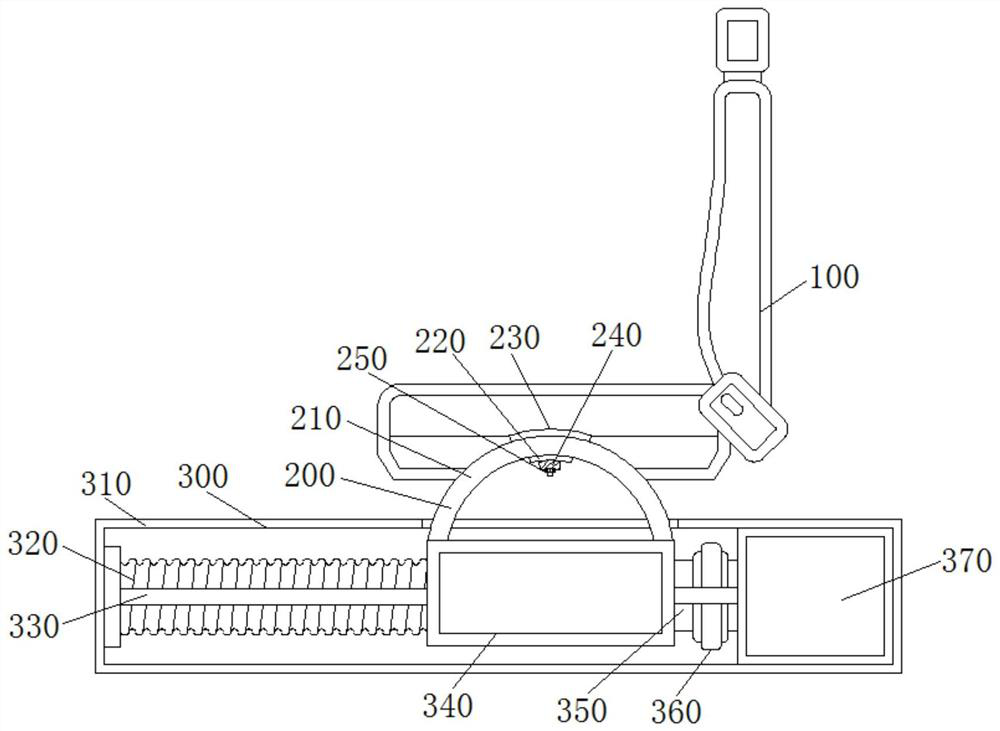

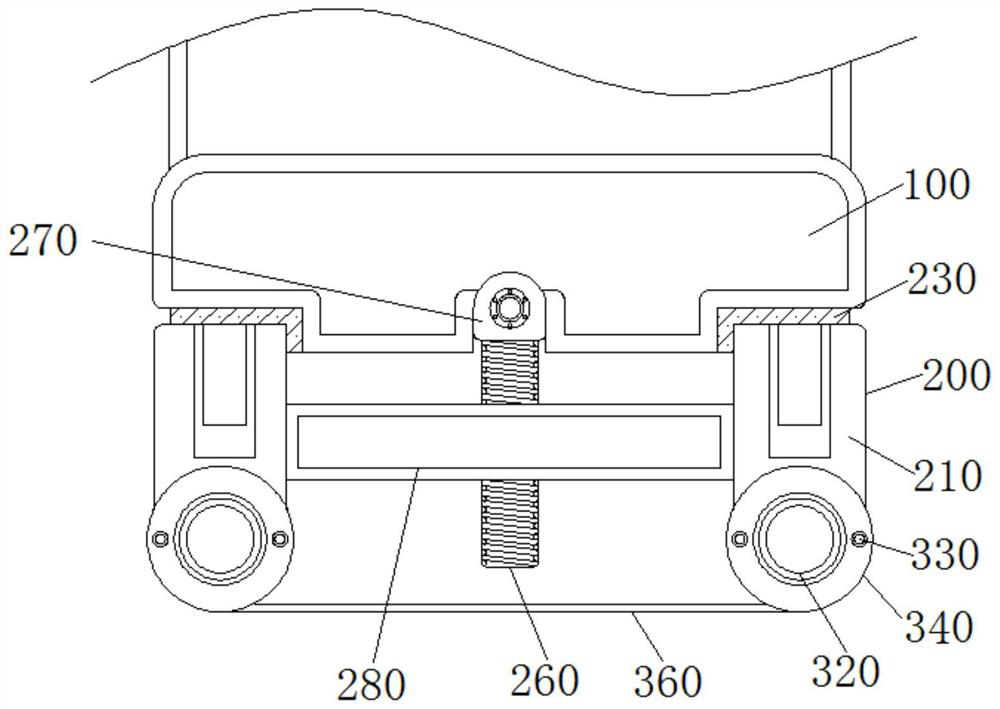

[0028] A driver's cab for construction machinery based on a control terminal to facilitate seat adjustment, including a seat body 100, the bottom end of the seat body 100 is connected with a corner mechanism 200, and the corner mechanism 200 includes a first fixing block 210, a first connecting block 220, The second connecting block 230, the third connecting block 240, the bolt 250, the worm wheel 260, the second fixing block 270, the first fixing rod 280, the first motor 290, the connecting shaft 2100, the second fixing rod 2110, the worm 2120 and the third Fixed rod 2130, the top of the first fixed block 210 is connected with the second connecting block 230, and the bottom end of the second connecting block 230 is fixed with the third fixed rod 2130, the first fixed block 210 is provided with two groups, and the first fixed The block 210 has a semicircular structure. The first fixed block 210 is symmetrically distributed under the seat body 100. A groove is opened inside the ...

Embodiment 2

[0033]Embodiment 2: A cab for construction machinery based on a control terminal to facilitate seat adjustment, including a seat body 100, the bottom end of the seat body 100 is connected with a corner mechanism 200, and the corner mechanism 200 includes a first fixed block 210, a first Connecting block 220, second connecting block 230, third connecting block 240, bolt 250, worm gear 260, second fixing block 270, first fixing rod 280, first motor 290, connecting shaft 2100, second fixing rod 2110, worm 2120 and the third fixed rod 2130, the top of the first fixed block 210 is connected with the second connecting block 230, and the bottom end of the second connecting block 230 is fixed with the third fixed rod 2130, the first fixed block 210 is provided with two groups, And the first fixed block 210 is a semicircular structure, the first fixed block 210 is symmetrically distributed under the seat body 100, the first fixed block 210 enables the seat body 100 to rotate at an overa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com