A multi-station synchronous processing equipment for aluminum alloy profiles

A technology of synchronous processing of aluminum alloy profiles, applied in the direction of metal processing equipment, metal processing, metal processing machinery parts, etc., can solve the problems of poor operation applicability, inconvenient use, waste of manpower, etc., and achieve labor saving, ease of use, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

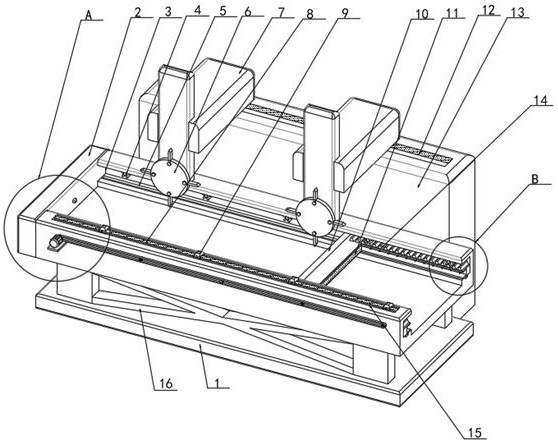

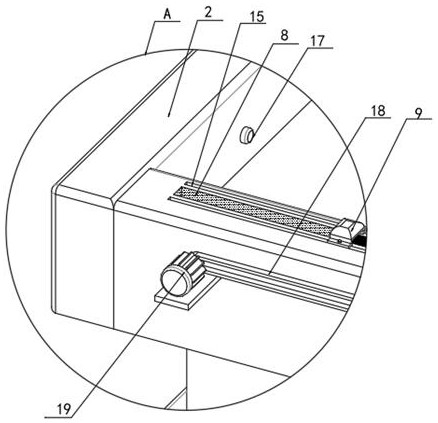

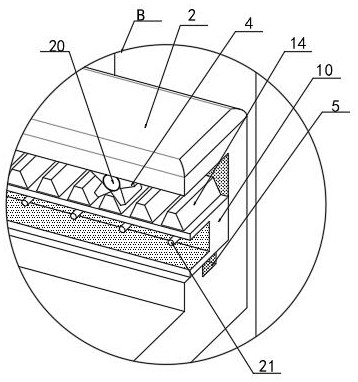

[0027] An embodiment of the present invention provides a multi-station synchronous processing equipment for aluminum alloy profiles, such as Figure 1-6 As shown, it includes a base 1, the top of the base 1 is fixedly connected with a support frame 16, the top of the support frame 16 is fixedly connected with a platform 2, the rear side of the platform 2 is fixedly provided with a support block 13, and the top of the support block 13 is provided with a plurality of processing equipment 7. The processing head 6 is fixed on the front side of the processing equipment 7, and the top of the support block 13 is provided with a second moving groove 12. Both ends of the two processing equipment 7 extend into the second moving groove 12 and are fixedly connected to the supporting block 13 by bolts , the inside of the platform 2 is provided with a first moving groove 3, the bottom of the first moving groove 3 is provided with a chute 5, the bottom of the fixed plate 10 extends into the i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap