Auxiliary conveying mechanism of automatic metal round-link chain flash butt welder

A technology of automatic flashing and conveying mechanism, which is applied in the direction of metal processing equipment, welding equipment, resistance welding equipment, etc. It can solve the problems of failure of conveying action, unstable operation, and the failure of the drive rod to be inserted into the chain link correctly, so as to achieve stable operation, Accurate stop position and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

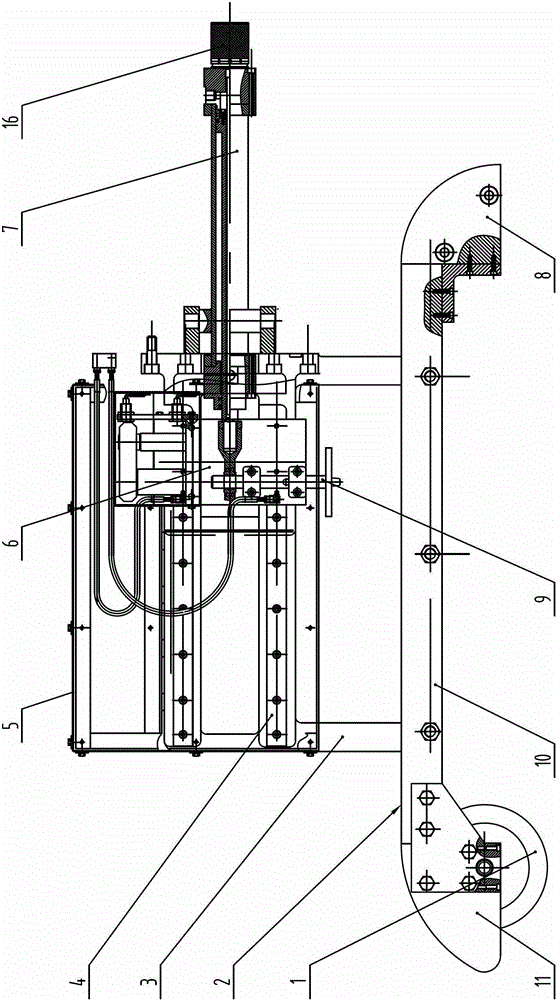

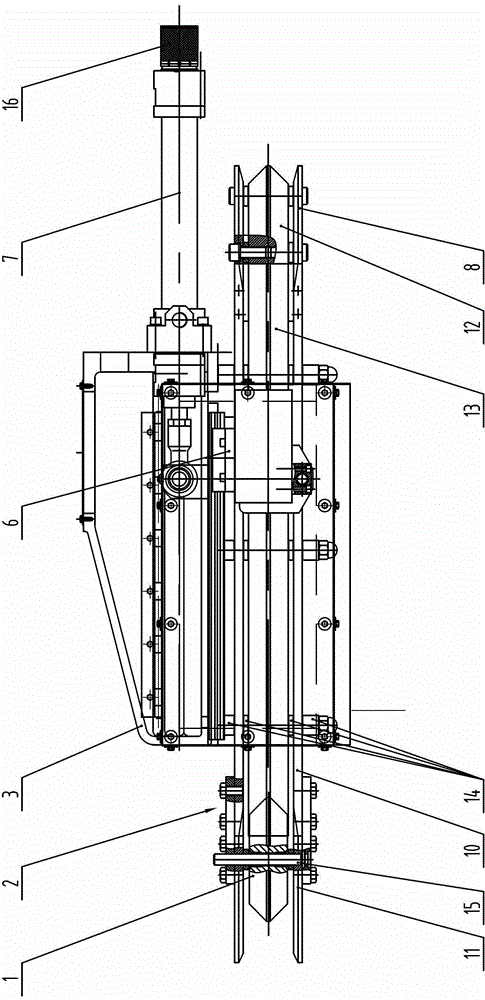

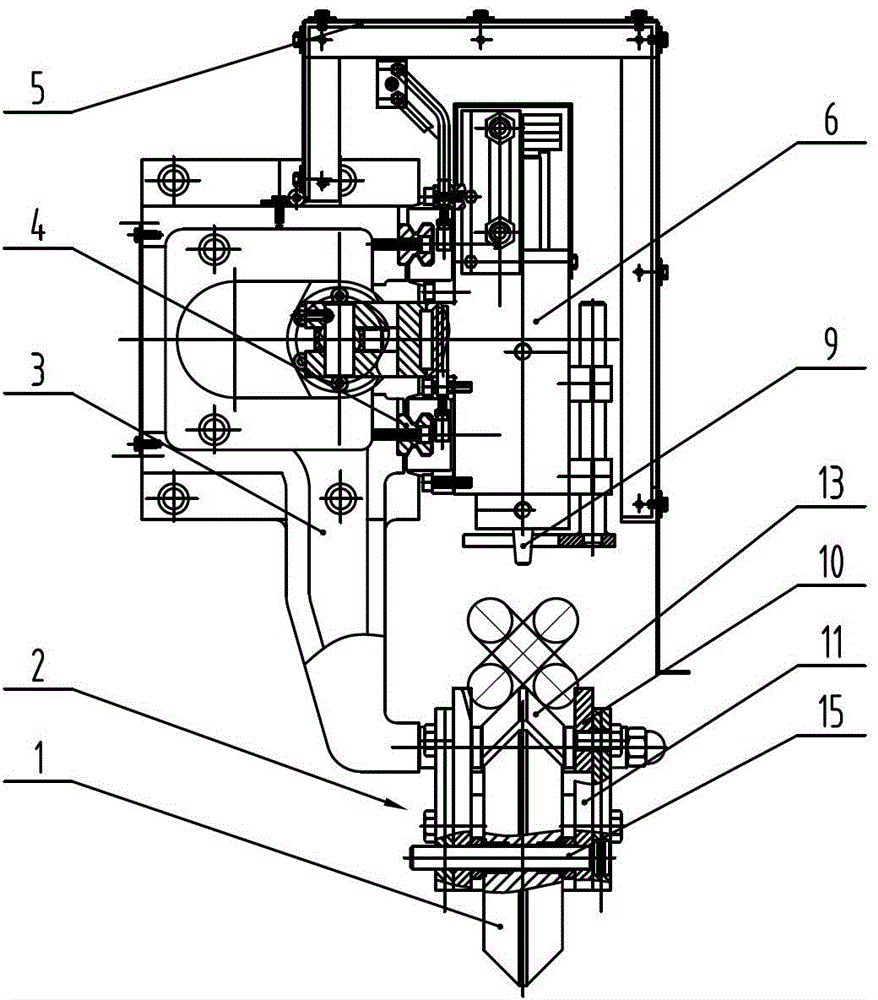

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Figure 1~Figure 3 Among them, including roller 1, sliding track 2, conveying slide body 3, linear guide rail 4, protective cover 5, vertical driving device 6, horizontal driving device 7, fan-shaped body side plate 8, driving rod 9, clip bar 10, roller side Plate 11, fan-shaped body 12, rhombic strip 13, spacer assembly 14, roller shaft 15, displacement sensor 16, etc.

[0016] Such as Figure 1~Figure 3 As shown, the present invention is an auxiliary conveying mechanism of a metal ring chain automatic flash butt welding machine, comprising a horizontal drive device 7 controlled by a displacement sensor 16, a vertical drive device 6 and a drive rod 9, and the drive rod 9 is fixed on the vertical drive On the device 6 , the vertical driving device 6 is fixed on the horizontal driving device 7 , and the horizontal driving device 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com