Transverse intracavity stapler with compact structure

A compact structure and stapler technology, applied in the field of medical devices, can solve the problems of slow recovery, large wound, unsuitable laparoscopic surgery channel, etc., and achieve the effect of reducing radial size, simple assembly, and compact assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

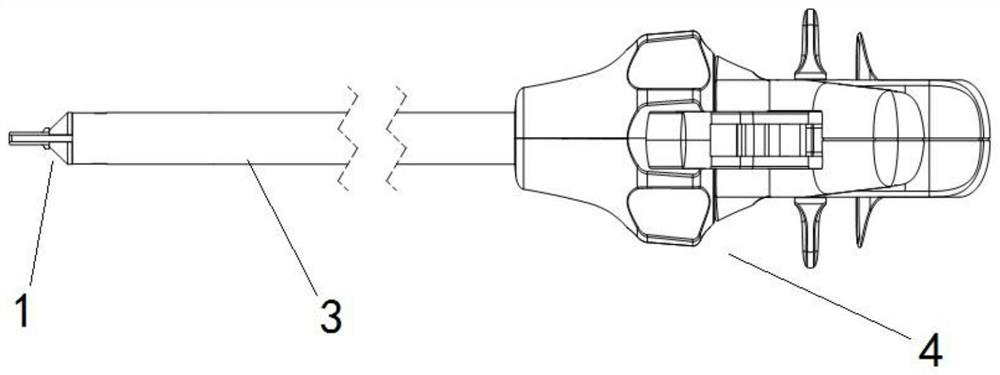

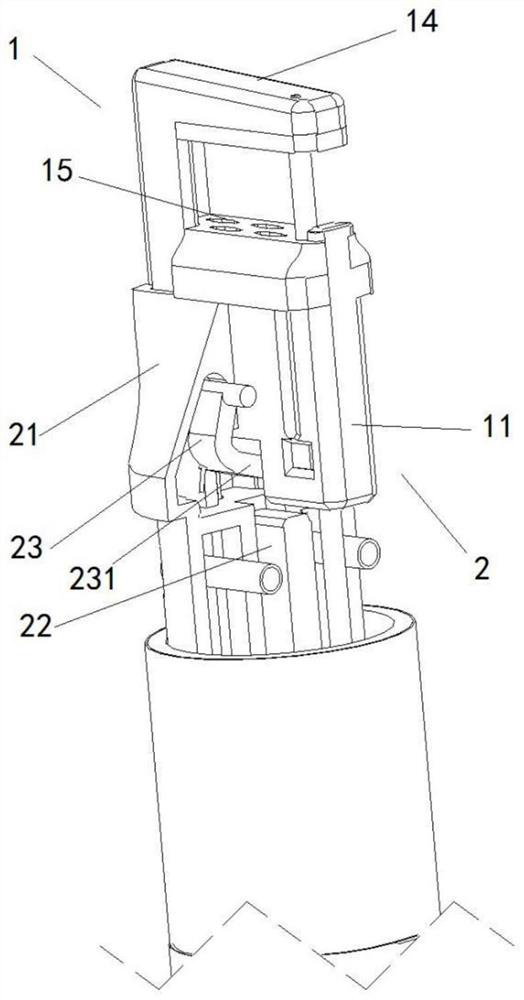

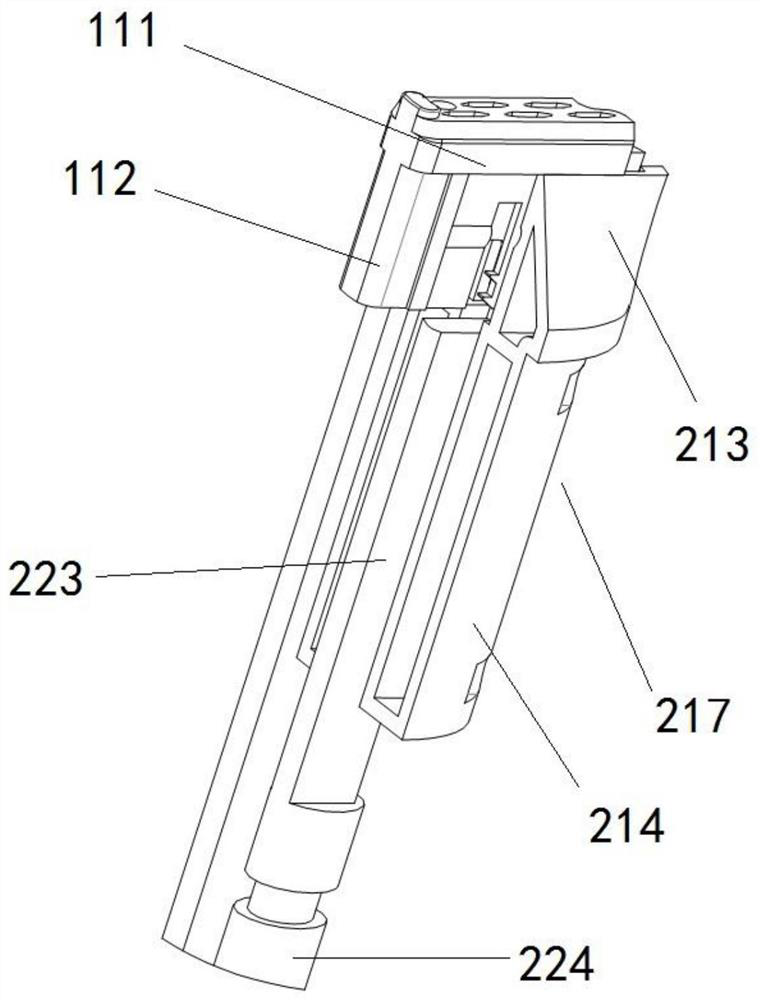

[0039] Such as Figure 1-17 As shown, the present embodiment provides a transverse endoluminal stapler with a compact structure. The surgical stapler includes an end effector 1, a drive assembly 2, a connecting outer tube 3 and a handle mechanism 4. The drive assembly 2 is used to drive When the end effector 1 performs suturing, the driving assembly 2 is at least partially arranged in the connecting outer tube 3, the end executing device is arranged at one end of the connecting outer tube 4, and the handle mechanism 4 is arranged at the other end of the end effector. The handle mechanism 4 It is connected to the drive assembly 2 in a transmission manner. For details, refer to the connection mode of the drive structure of the stapler in the prior art. By controlling the handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com