Water-soluble coenzyme Q10 beverage and production method thereof

A water-soluble, coenzyme technology, applied in the field of food processing, can solve the problems of low bioavailability, poor water solubility, instability, etc., and achieve the effects of high solubility, fast dissolution speed, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

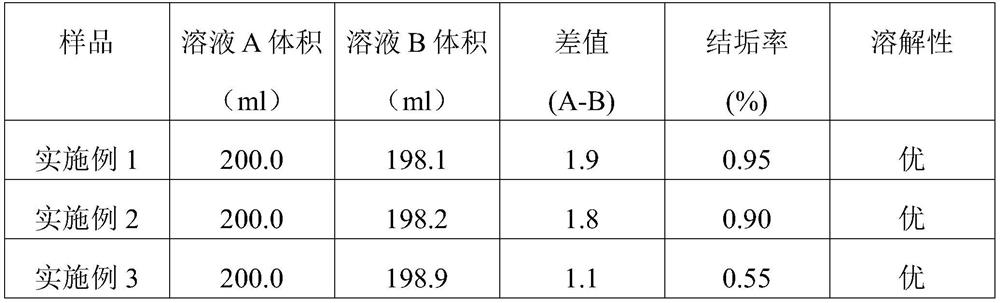

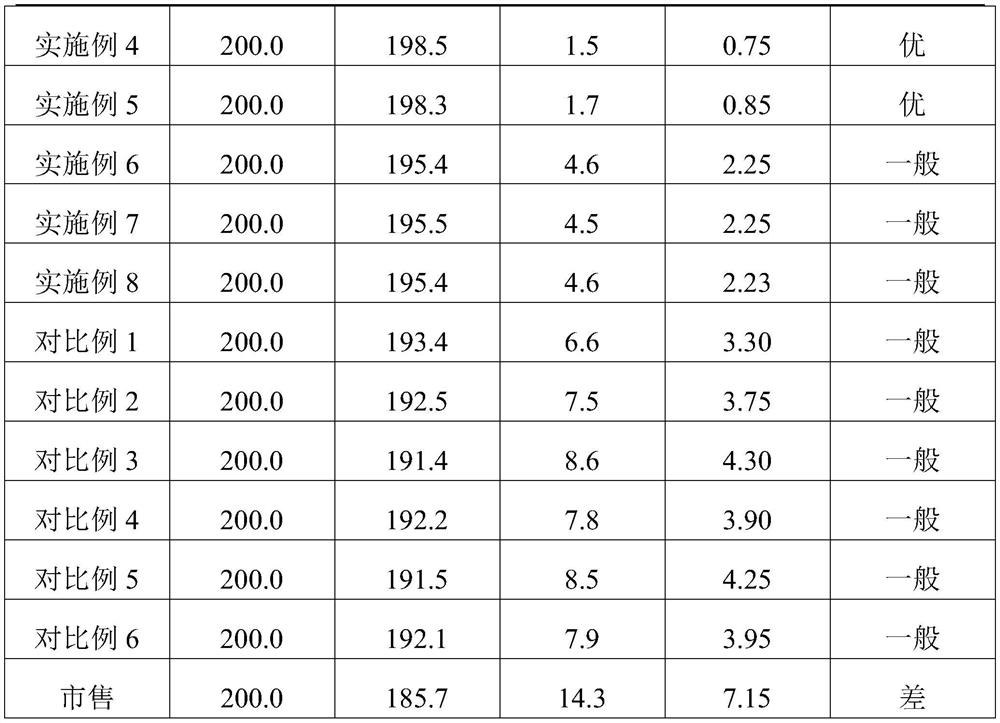

Embodiment 1

[0023] A water-soluble coenzyme Q 10 Beverage, including the following ingredients by weight: Coenzyme Q 10 5 parts, 0.3 parts of emulsifier, 1 part of stabilizer, 1 part of oligoisomaltose, 3 parts of vitamin B2, 2 parts of piperonic acid;

[0024] The emulsifier is prepared from myristic fatty acid ester, sucrose fatty acid ester, ascorbyl palmitate, and poloxamer 407, and the weight ratio is 1:0.3:1.1:0.03;

[0025] The stabilizer is made of acrylate, ethylenediaminetetraacetate, and rice germ oil, and the weight ratio is 0.3:0.1:1;

[0026] In the emulsifier, the HLB value of myristic fatty acid ester is 10, the HLB value of sucrose fatty acid ester is 13, the HLB value of ascorbyl palmitate is 8, and the HLB value of poloxamer 407 is 13.

Embodiment 2

[0028] A water-soluble coenzyme Q 10 Beverage, including the following ingredients by weight: Coenzyme Q 10 30 parts, 11 parts of emulsifier, 8 parts of stabilizer, 10 parts of oligoisomaltose, 6 parts of vitamin B2, 4 parts of piperonic acid;

[0029] The emulsifier is composed of myristic fatty acid ester, sucrose fatty acid ester, ascorbyl palmitate, and poloxamer 407, in a weight ratio of 3:2:4:0.05;

[0030] The stabilizer is composed of acrylate, ethylenediaminetetraacetate, and rice germ oil, and the weight ratio is 2:0.6:4.

[0031] In the emulsifier, the HLB value of myristate fatty acid ester is 15, the HLB value of sucrose fatty acid ester is 18, the HLB value of ascorbyl palmitate is 12, and the HLB value of poloxamer 407 is 18.

Embodiment 3

[0033] A water-soluble coenzyme Q 10 Beverage, including the following ingredients by weight: Coenzyme Q 10 18 parts, 5.5 parts of emulsifier, 6 parts of stabilizer, 4 parts of oligoisomaltose, 4 parts of vitamin B2, 3 parts of piperine;

[0034] The emulsifier is prepared from myristic fatty acid ester, sucrose fatty acid ester, and ascorbyl palmitate, Poloxamer 407, with a weight ratio of 2:1.2:2.6:0.04;

[0035] The stabilizer is made of acrylate, ethylenediaminetetraacetate and rice germ oil, and the weight ratio is 1.6:0.3:3;

[0036] In the emulsifier, the HLB value of myristate fatty acid ester is 13, the HLB value of sucrose fatty acid ester is 15, the HLB value of ascorbyl palmitate is 10, and the HLB value of poloxamer 407 is 15.

[0037] The water-soluble coenzyme Q of Examples 1 to 3 above 10 Drinks, using the following preparation methods:

[0038] S1. Emulsifier dissolution: According to the above weight parts of raw materials, the emulsifier and ethanol are mixed and dil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com