Maintenance equipment demand prediction and analysis system based on big data

A technology for maintenance equipment and demand forecasting, applied in the field of forecasting analysis, can solve the problems of considerable investment, prone to damage, failure, large interior space and load capacity, etc., so as to improve the voyage rate, reduce the burden, and improve the utilization of warehouse space. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

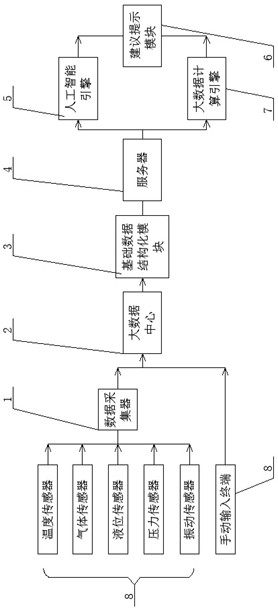

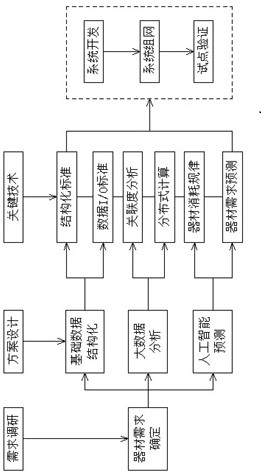

[0022] see Figures 1 to 3 It is a system structure diagram, flow chart, and neural network calculation schematic diagram of the present invention, a maintenance equipment demand prediction and analysis system based on big data, including a ship, and the prediction analysis system is set on the inside of the ship. Including server 4, server 4 is connected with artificial intelligence engine 5, server 4 is connected with big data calculation engine 7, artificial intelligence engine 5, big data calculation engine 7 are connected with suggestion prompt module 6, server 4 has basic data structure through network connection The basic data structuring module 3 is connected to the big data center 2 through the network, the big data center 2 is connected to the data collector 1, and the data collector 1 is connected to a sensor group through a wire, and the sensor group includes but not limited to a temperature sensor, Gas sensors, liquid level sensors, pressure sensors, vibration sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com