T-shaped bolt with tenons

A mortise and bolt technology, applied in the direction of bolts, screws, nuts, etc., can solve the problems of bolts falling out of groove, T-shaped bolts can not fully meet the anti-loosening and anti-slip requirements, and affect operational safety, etc., to achieve increased friction, enhanced strength, Avoid the effect of bolt degrooving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

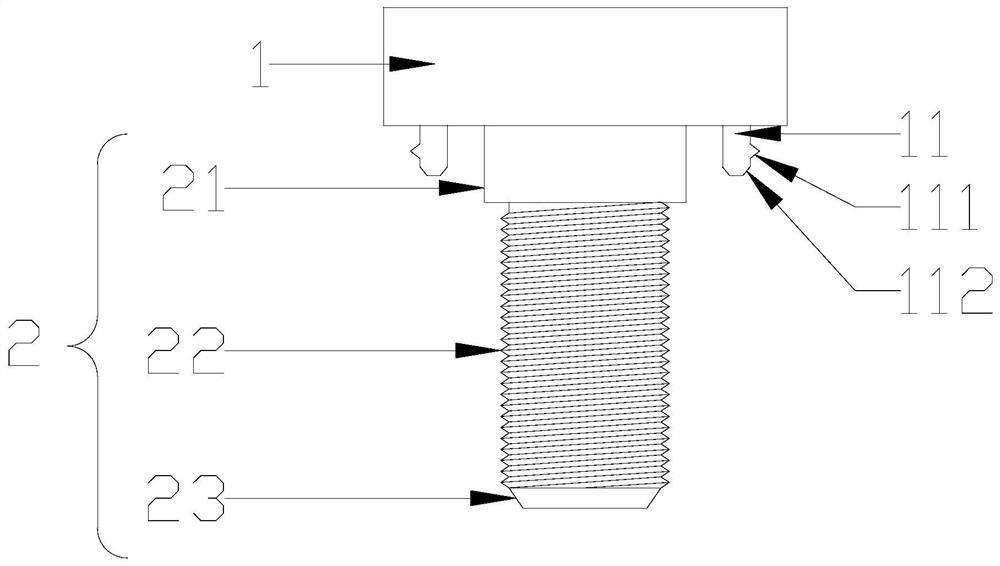

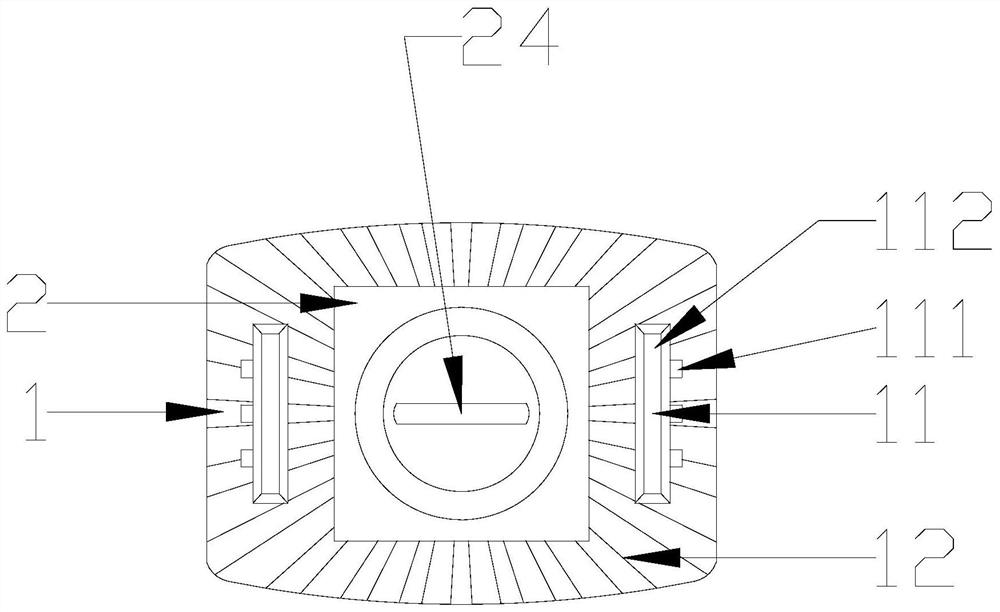

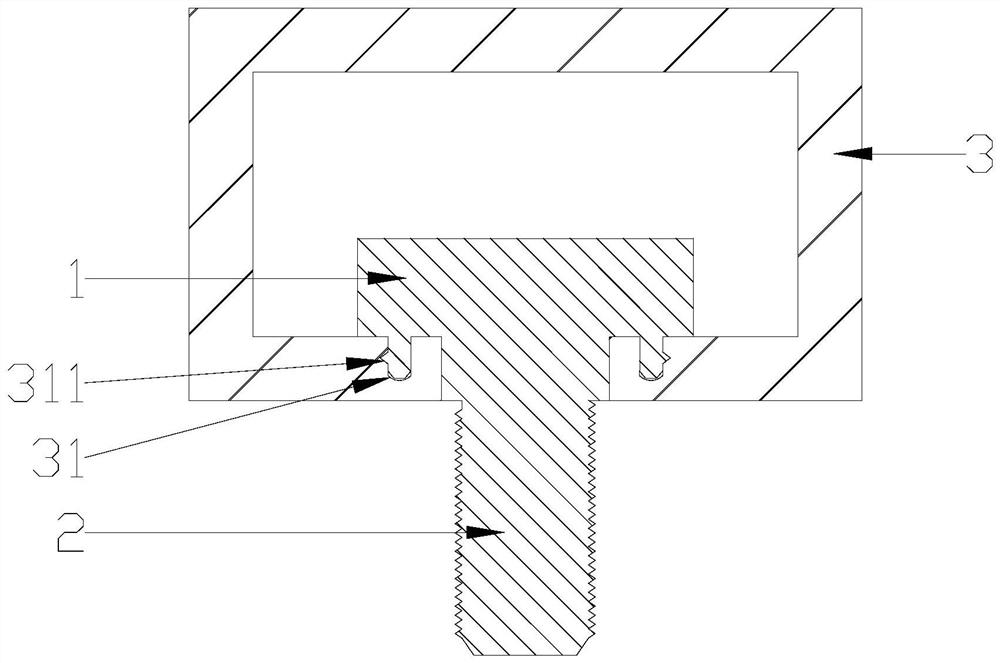

[0018] refer to Figure 1 to Figure 3 , the present invention is a T-shaped bolt with tenons, including a screw head 1 and a screw rod 2, and the screw rod 2 includes a square anti-rotation neck section 21 and a threaded section 22 provided with external threads, the screw head 1 and the screw rod 2 The threaded sections 22 are respectively located at both ends of the anti-rotation neck section 21. The screw head 1 is rectangular and has several tenons 11 on the side close to the screw rod 2. The long side of the rectangular screw head 1 protrudes outwards to form an arc Shape, the side of the screw head 1 close to the screw rod 2 is provided with several ribs 12, the tenon 11 is located near the short side of the rectangle of the screw head 1, and the side of the tenon 11 is provided with several pointed protrusions 111, so The end of the tenon 11 is provided with a first guide section 112, the first guide section 112 is truncated, and the cross-sectional area of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com