Virtual cathode arc propeller adopting dielectric barrier discharge

A dielectric barrier discharge and virtual cathode technology, applied in electrical components, thrust reversers, machines/engines, etc., can solve the problems of arc interruption, non-linear growth of lap resistance, and reduction of electric power of arc heating working fluid, etc. Practicality and the effect of prolonging on-orbit life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the content of the present invention, through which the content of the present invention will be further clarified. The following specific embodiments are described only to illustrate different aspects of the present invention and should not be construed as limiting the scope of the present invention.

[0025] The main idea of the present invention is that the tip discharge is replaced by a dielectric barrier discharge that has no ablation effect on the cathode, so that the problem of electrode ablation of the thruster can be avoided and the practicability of the arc thruster can be improved.

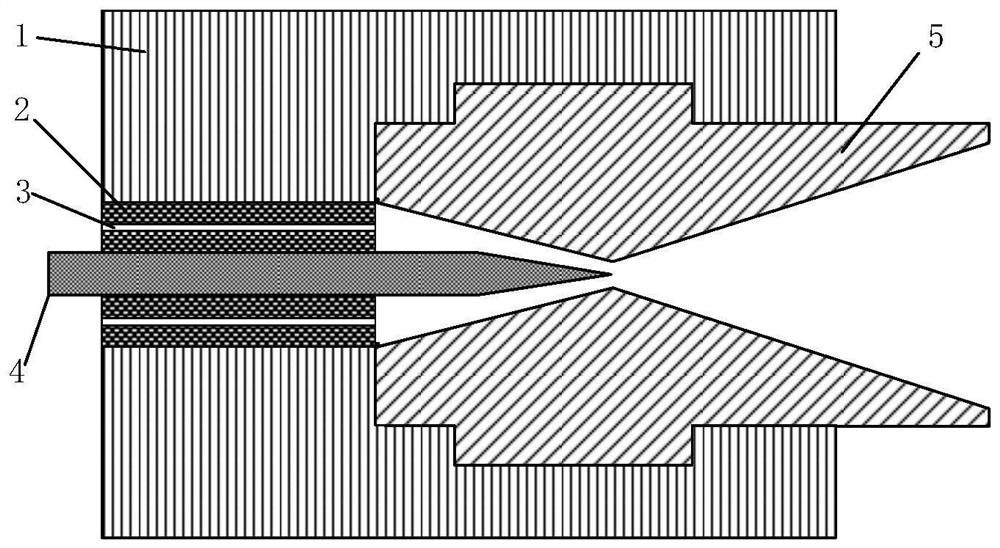

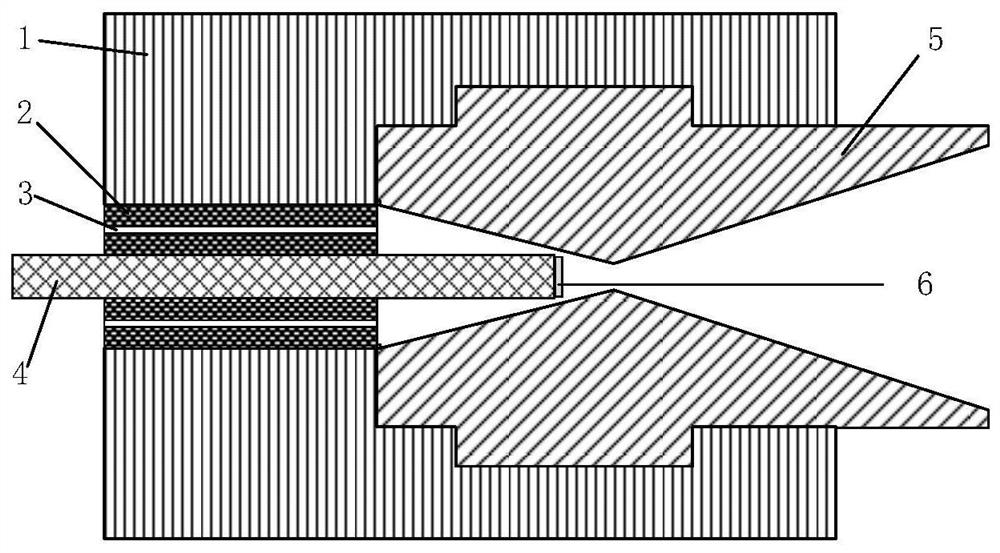

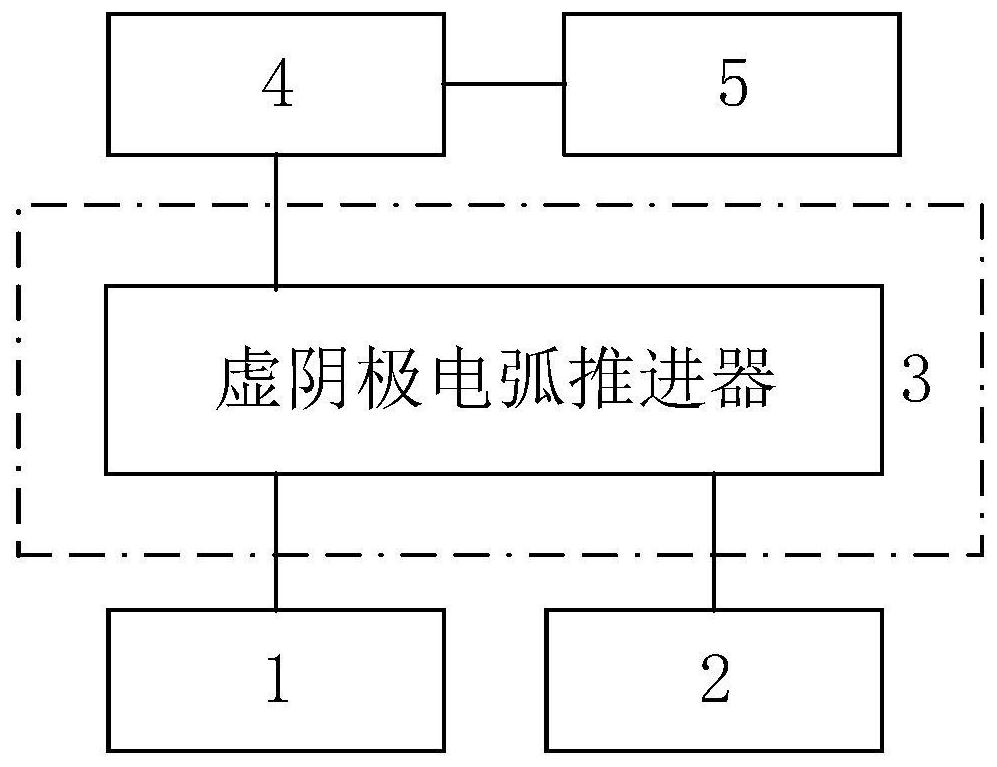

[0026] refer to figure 2 as shown, figure 2 It is a schematic cross-sectional view of a dielectric barrier discharge virtual cathode arc thruster in an embodiment of the present invention. The dielectric barrier discharge virtual cathode arc thruster in this embodiment includes a metal sleeve 1, a sealing member 2, an air inlet 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com