Stratum deflecting property evaluation method

An evaluation method and stratum technology, applied in the direction of earthwork drilling and production, borehole/well components, etc., can solve the problems of instrument stress and calculation result deviation, inability to accurately judge stratum deflection, etc., so as to avoid operation failure and evaluate The method is simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the application clearer, the embodiments of the application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

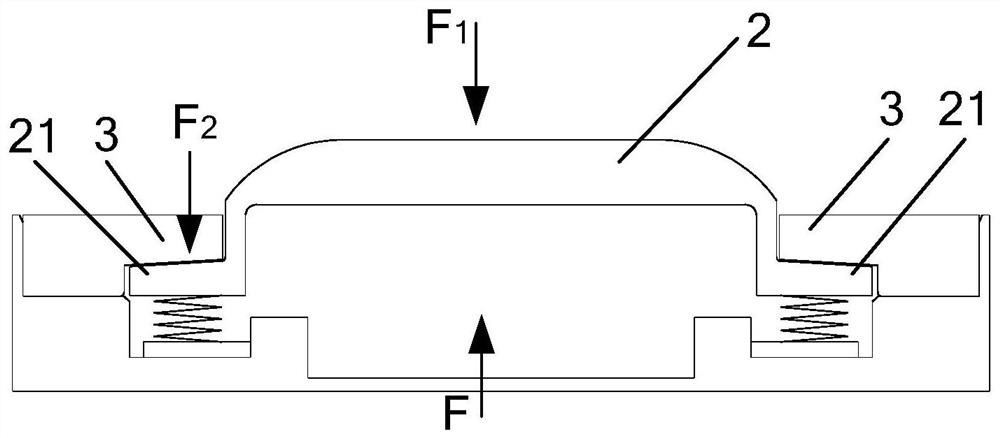

[0020] During the directional drilling process of the push-on rotary steerable drilling system, the on-site engineer corrects the pressure of the hydraulic system according to the deflection effect of the rotary steerable instrument in the formation (the change of the well deflection), thereby correcting the resultant steering force to achieve deflection deflection. Effect control. However, due to the different characteristics of the formation such as softness and hardness, the reaction force of the formation to the pushing rib is not necessarily 100% (that is, the reaction force of the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com